Method for producing lightweight partition board by sulfur fixation fly ash

A technology of lightweight partition board and fly ash, which is applied in the direction of solid waste management, sustainable waste treatment, climate change adaptation, etc., can solve problems such as environmental pollution and large land occupation, and achieve significant economic benefits and simple production equipment , Huge economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

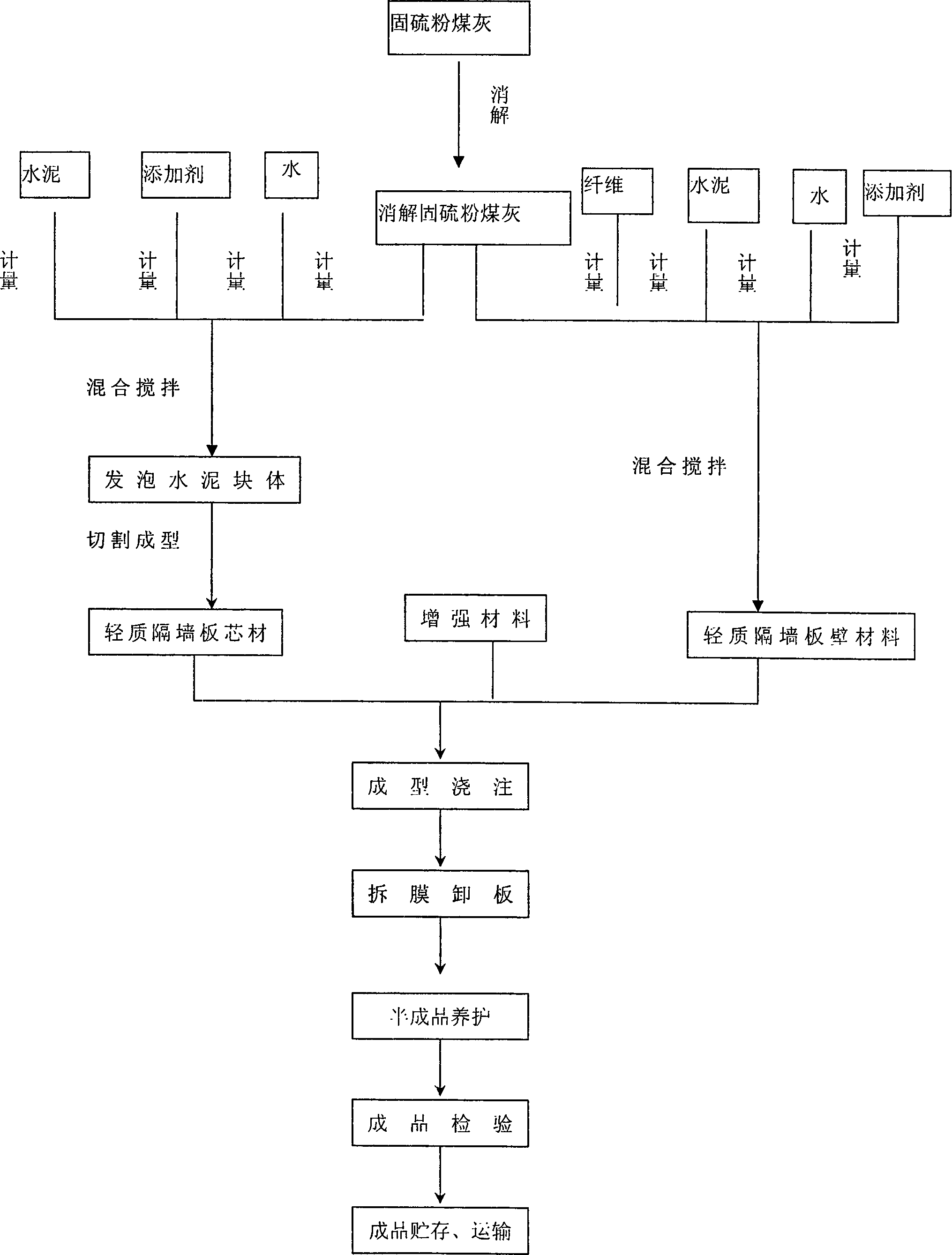

Method used

Image

Examples

Embodiment 1

[0025] Take 120 kg of sulfur-fixed fly ash for natural digestion. Then 20 kg of digested sulfur-fixed fly ash is mixed with 20 kg of cement, appropriate amount of water, and additives to prepare a foamed cement block, which is dried and cut into a lightweight partition board core material. Mix and stir 80 kg of digested sulfur-fixed fly ash, 50 kg of cement, appropriate amount of water, 15 kg of plant fiber and additives. After 20 minutes, the core material and wall material of the lightweight partition board are molded and casted in the lightweight partition board machine and mold. During molding, steel wire is added to the wall material as a reinforcing material, and the film and board are removed within 3 days.

Embodiment 2

[0027] Get 80 kg of sulfur-fixed fly ash for water spray digestion. Then mix and stir with 60 kilograms of cement, appropriate amount of water, 12 kilograms of plant fibers and additives. After 20 minutes, the polystyrene foam board core material and the above-mentioned mixture are molded and casted in a lightweight partition board machine and mold. During molding, steel wire mesh is added to the wall material as a reinforcing material, and the film and board are removed within 3 days.

Embodiment 3

[0029] Get 120 kg of sulfur-fixed fly ash for water spray digestion. Then 20 kg of digested sulfur-fixed fly ash is mixed with 20 kg of cement, appropriate amount of water, and additives to prepare a foamed cement block, which is dried and cut into a lightweight partition board core material. Mix and stir 90 kg of digested sulfur-fixed fly ash, 70 kg of cement, appropriate amount of water, 10 kg of plant fiber, 1 kg of PP fiber, 2 kg of glass fiber and additives. After 20 minutes, the core material and wall material of the lightweight partition board are molded and casted in the lightweight partition board machine and mould. During molding, glass fiber mesh and steel wire mesh are added to the wall material as reinforcement materials, and the film and board are removed within 3 days .

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com