Compatibility and production method of pholiota nameko cultivation material

The technology of cultivation material and cultivation material for the mushroom is applied in the directions of fertilizer mixture, fertilization device, application, etc., which can solve the problems of waste of biomass resources, low utilization rate, large output of tea residue, etc., and achieves widening raw material channels, nutrient balance, high yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

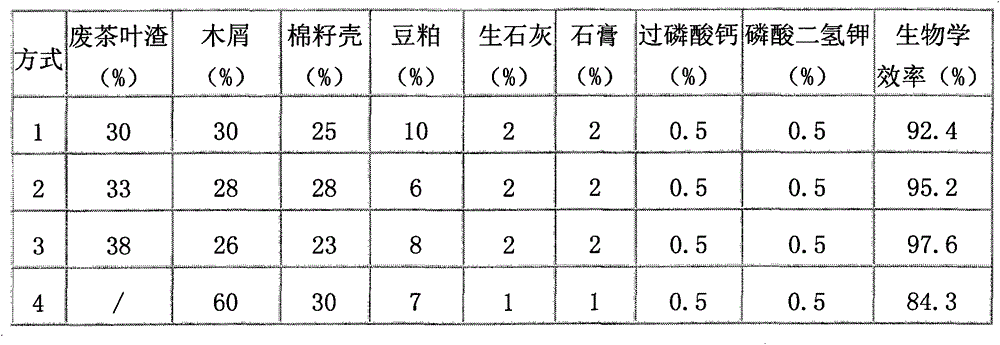

[0023] Method 1: In this embodiment, the mushroom cultivation material includes the following components and mass ratios: 30% of waste tea leaves, 30% of wood chips, 25% of cottonseed husks, 10% of soybean meal, 2% of quicklime powder, 2% of gypsum, and superphosphoric acid. Calcium 0.5%, potassium dihydrogen phosphate 0.5%, all are the mass of dry matter, and the sum of the proportions is 100%.

[0024] Production Method:

[0025] ①Pre-wetting: Mix the waste tea residue, sawdust, and cottonseed husk dry material, and pre-wet it with 2% lime water solution for 2 hours to keep the water content of the mixture at 50%-55%;

[0026] ②Mixing materials: Mix soybean meal, gypsum, and calcium superphosphate dry materials evenly, add them to the pre-wetted mixture, and then slowly add potassium dihydrogen phosphate aqueous solution, stir while adding, and stir well to make the content of the cultivation material The water volume is kept at 65%;

[0027] ③Bagging: Use a high-pressure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com