Preparation method of high-purity levorotatory borneol

A high-purity levoborneol technology, applied in the field of pharmacy, can solve the problems that do not meet the purity requirements of moxa tablets, low levoborneol content, and has not been seen yet, and achieve the effects of low cost, high production efficiency, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

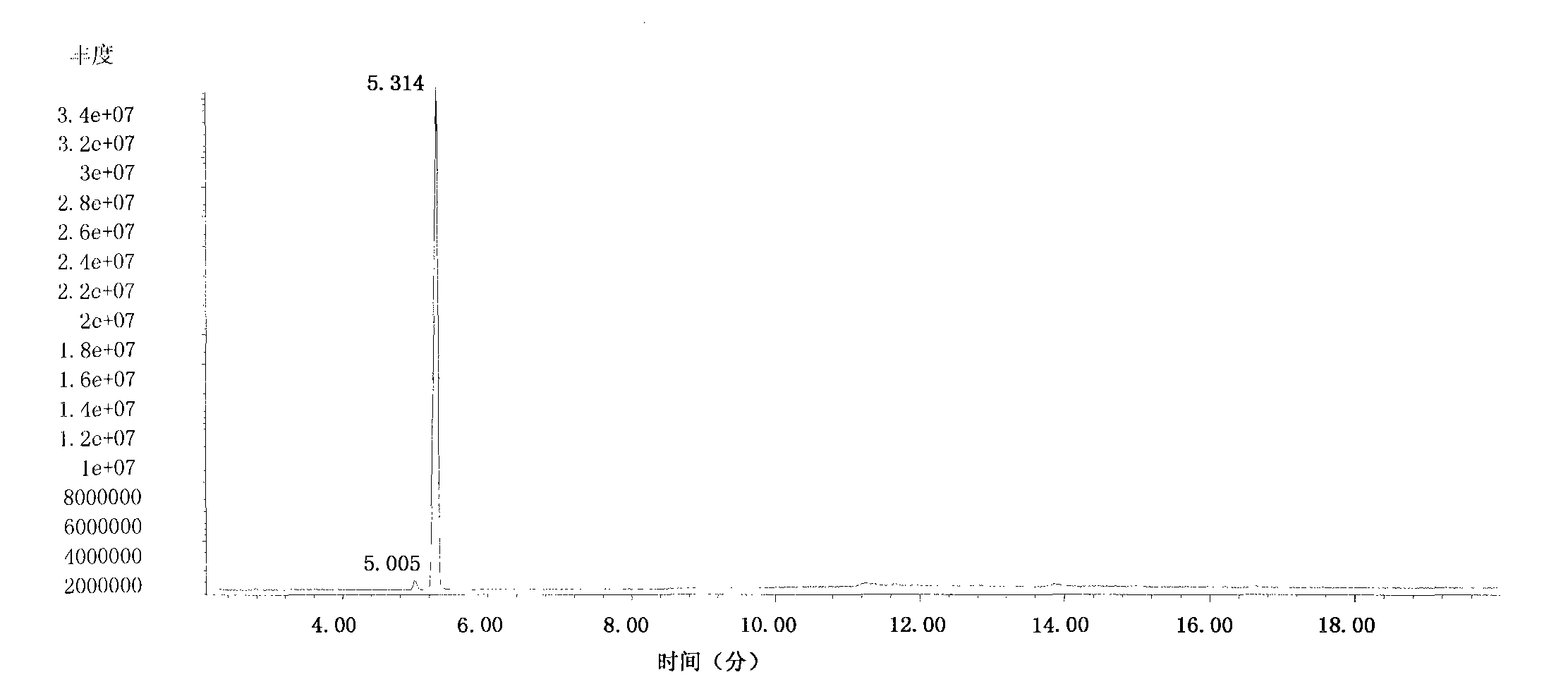

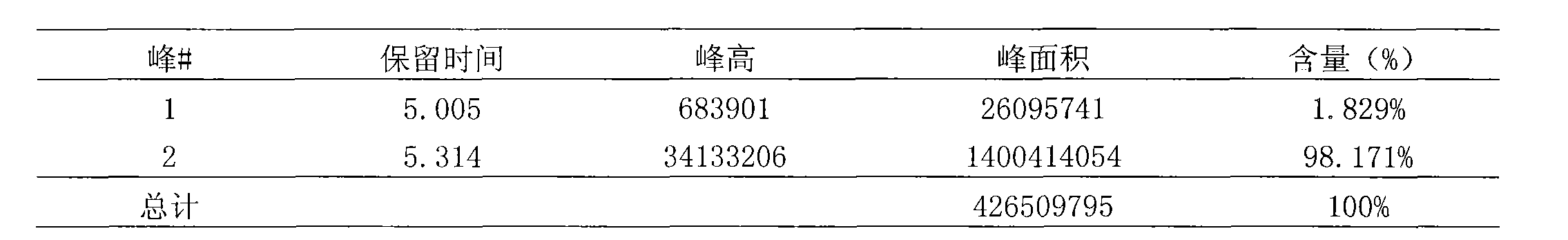

Image

Examples

Embodiment 1

[0031] Step 1, take the commercially available crude product L-borneol (the content of L-borneol is 66.3%), centrifuge and dry it and then dry it.

[0032] Step 2, the above solid is dissolved in 2 times the amount (relative to the weight of the crude product L-borneol) in absolute ethanol.

[0033] Step 3: Add 0.02 times (relative to the weight of crude L-borneol) sodium metal in batches to the above solution under cooling conditions, and react at 0° C. for 5 hours after the addition is complete.

[0034] Step 4: Pour the above reaction solution into 4 times the amount (relative to the weight of crude L-borneol) of water, let it stand for 2 hours, and filter under reduced pressure.

[0035] Step 5, the obtained filter cake is added to 2 times the amount (relative to the weight of the crude product L-borneol) of petroleum ether, heated to 50°C, and the lower aqueous phase is separated, and the organic phase is cooled to -20°C, and a large number of flaky crystals appear. Filt...

Embodiment 2

[0037] Step 1, take the commercially available crude product L-borneol (the content of L-borneol is 66.3%), centrifuge and dry it and then dry it.

[0038] Step 2, dissolve the solid in 4 times the amount (relative to the weight of the crude product L-borneol) in absolute ethanol.

[0039] Step 3, add 0.1 times the amount (relative to the weight of crude L-borneol) of sodium metal in batches to the above solution under cooling conditions, and react at 0° C. for 2 hours after the addition is complete.

[0040] Step 4: Pour the above reaction solution into 10 times the amount (relative to the weight of crude L-borneol) of water, let it stand for 1 hour, and filter under reduced pressure.

[0041] Step 5, the obtained solid was added to 1 times the amount (relative to the weight of crude L-borneol) of petroleum ether, heated to 60°C, the lower aqueous phase was separated, and the organic phase was cooled to -5°C, a large number of crystals appeared. Filter and dry to obtain whit...

Embodiment 3

[0043] Step 1, take the commercially available crude product L-borneol (the content of L-borneol is 66.3%), and spin dry by centrifugation.

[0044] Step 2, the above solid is dissolved in 1 times the amount (relative to the weight of the crude product L-borneol) in methanol.

[0045] Step 3, adding 0.05 times the amount (relative to the weight of the crude product L-borneol) of sodium borohydride in batches to the above solution, after the addition, keep the temperature at 60°C and continue the reaction for 2 hours.

[0046] Step 4: Pour the above reaction solution into 4 times the amount (relative to the weight of crude L-borneol) of water, let it stand for 2 hours, and filter under reduced pressure.

[0047] Step 5, add the obtained solid to 1 times the amount (relative to the weight of the crude product L-borneol) of ethanol, add 0.3 times the amount (relative to the weight of the crude product L-borneol) of water, heat to 60 ° C, and all the solids are dissolved. The tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com