Biodegradable lubricating grease

A biodegradable and lubricating grease technology, used in lubricating compositions, petroleum industry, etc., can solve the problems of poor biodegradability of mineral base oil, endanger human health, and be difficult to biodegrade, and achieve improved anti-wear performance and high-temperature oxidation stability. performance, reduce mechanical noise, and outstanding wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

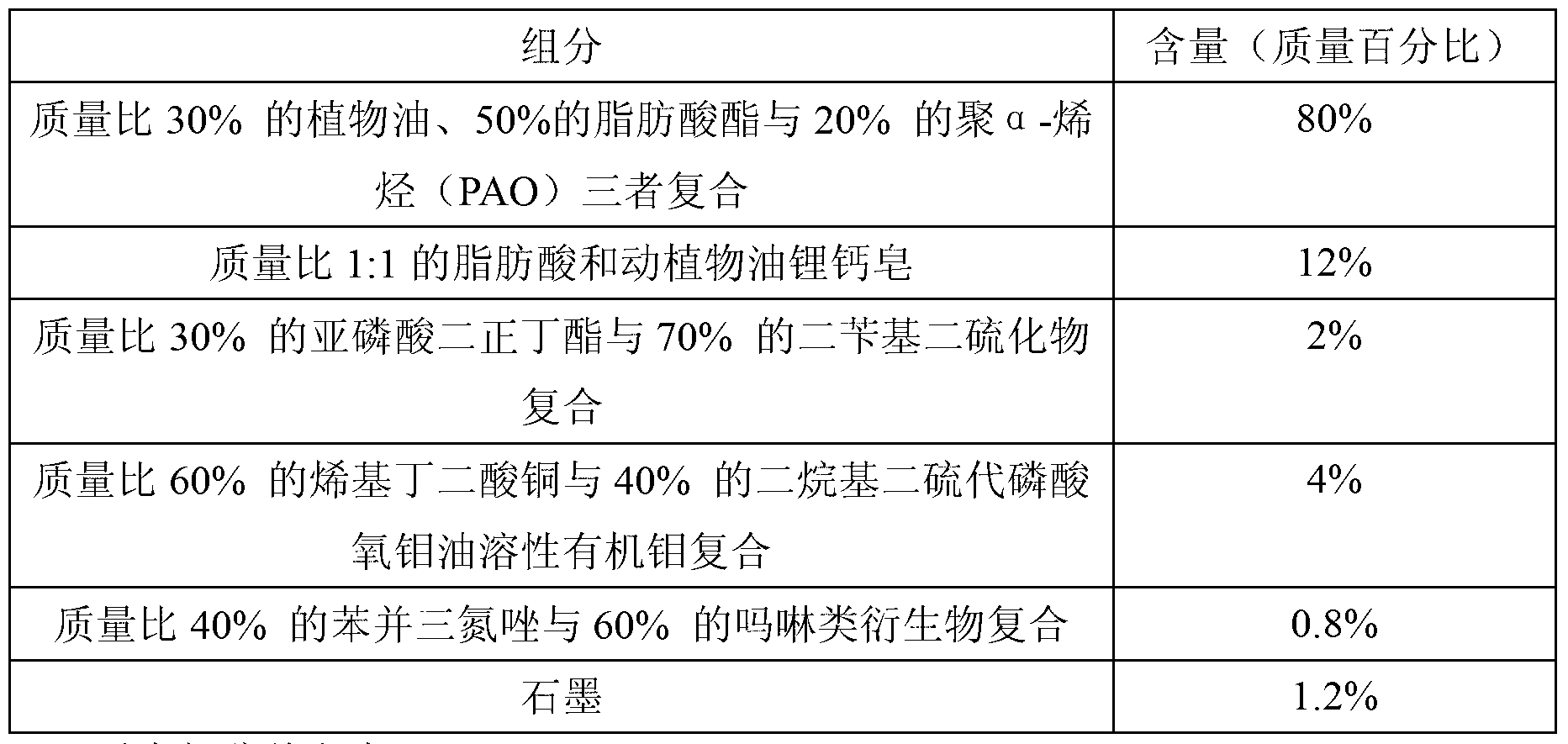

Embodiment 1

[0020] It is prepared by blending the following components in mass percentage:

[0021]

[0022] The sum of the above components is 100%.

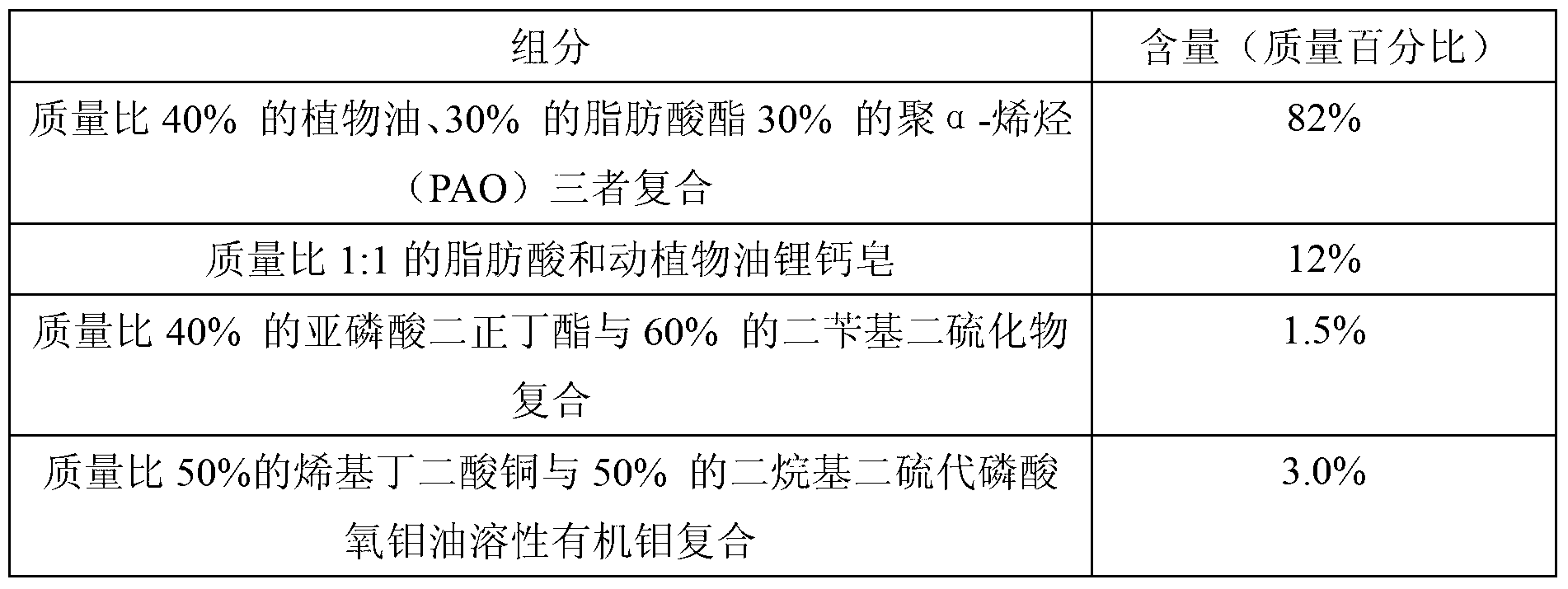

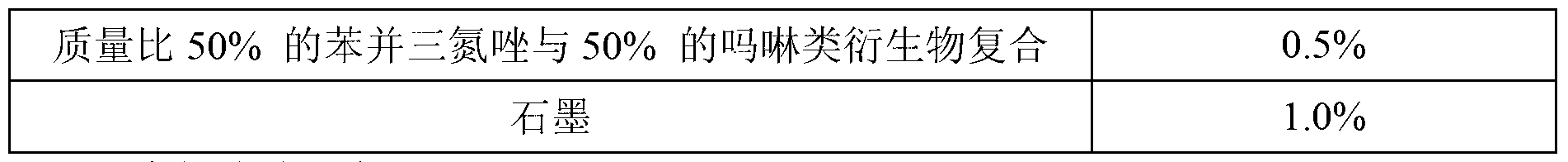

Embodiment 2

[0024] It is prepared by blending the following components in mass percentage:

[0025]

[0026]

[0027] The sum of the above components is 100%.

Embodiment 3

[0029] It is prepared by blending the following components in mass percentage:

[0030]

[0031] The sum of the above components is 100%.

[0032] Measure through provincial technical supervision department, every physicochemical index of product of the present invention all reaches service requirement, and table 1 is every typical physicochemical index of embodiment 3:

[0033] Table 1 Typical physical and chemical indicators of biodegradable grease

[0034]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com