Preparation method of self-color-developing dosemeter for individual dose monitoring

A dosimeter and self-display technology, which is applied in the field of preparation of self-color dosimeters, can solve the problems that it cannot be used as a personal dosimeter, and achieve the effect of low detection limit and optimized preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] A preparation method for a self-color dosimeter for personal dose monitoring, the method comprises the following steps:

[0029] (1) Dissolve the base material completely with a diluent; (2) Dissolve the color-changing dye with a diluent and filter out the insoluble matter; (3) Mix and stir the solutions obtained in steps (1) and (2) evenly; (4) Use The film is made by casting method; the color-changing dye used is a diacetylene-like compound, and the ratio of the color-changing dye to the base material is 1:10~2:1.

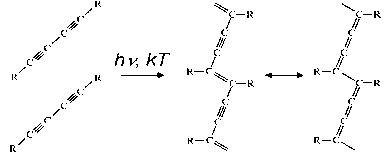

[0030] The color-changing dye is diacetylenoid compound 344 (R, R' is (CH 2 ) 3 OCONH(CH 2 ) 3 CH 3 ), diacetylene-like compound 166 (R, R' is OCONH (CH 2 ) 5 CH 3 ), butadiyne-like compound 156 (R is CH 2 OCONH (CH 2 ) 5 CH 3 , R' is CH 2 OCONH (CH 2 ) 4 CH 3 ), any one of pentadecanediyne carboxylic acid PCDA, tricosanediyne carboxylic acid TCDA or a mixture thereof.

[0031] The base material is PVA, PVB, PVC or nylon.

[0032] The dilu...

Embodiment 1

[0037] Weigh 40 parts of PVC base material, add it into THF diluent, stir for 2 hours to dissolve it, and make the solute content 0.05g / mL at the same time, so that it has a suitable viscosity. Another 20 parts of PCDA color-changing dye was weighed, dissolved in tetrahydrofuran as a diluent, and prepared into a 0.01 g / mL solution, and the insoluble matter was filtered off. The above two solutions were mixed, and the dosimeter film was prepared by casting method, and the measured film thickness was about 180 μm.

[0038] In order to investigate the background difference of the prepared dosimeter, the middle part of the film was selected, and 5 pieces of 1cm×1cm film were cut to measure the background absorbance. As shown in Table 1 below, the relative standard deviation of the background measurement is about 1%.

[0039]

[0040] Table 1 Background absorbance measurement

[0041]

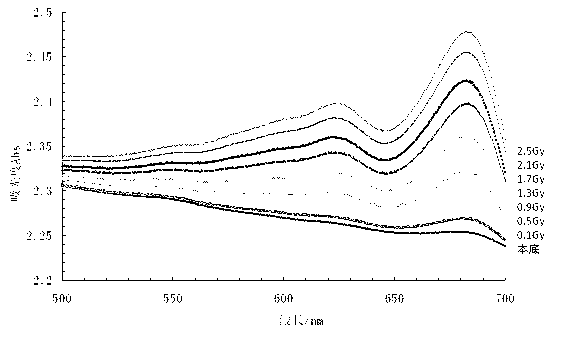

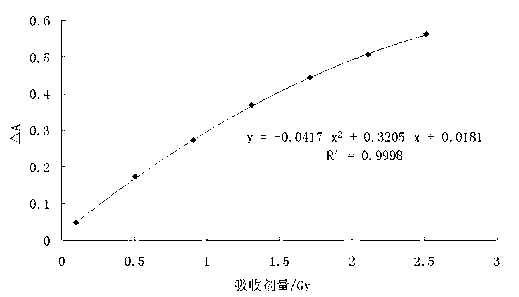

[0042] In order to investigate the radiation dosimetry performance of the dosimeter, an irr...

Embodiment 2

[0046] The steps and method are the same as in Example 1. The difference is that the number of parts of the base material and color-changing dye added is different, and when dissolving the color-changing dye and base material, the dissolution temperature is controlled to be 50 ° C, and the temperature of the mixed solution is cooled to room temperature. The casting method is used to make the film, as shown in the table below:

[0047] Table 2 The number of parts of color-changing dye and matrix material added

[0048] Color changing dye (parts) Base material (parts) 1 20 200 2 20 80 3 20 20 4 20 10

[0049] The dosimeter prepared according to the number of parts of the color-changing dye and the base material listed in the above table is irradiated in the gamma irradiation standard device. When the irradiation dose changes from 0.1Gy to 3Gy, the color of the dosimeter changes from white to for blue.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com