Through-hole-priority dual damascene copper interconnection method for reducing coupling capacitance of redundant metal

A redundant metal, through-hole priority technology, applied in the direction of circuit, electrical components, pattern surface photolithography, etc., to achieve the effect of reducing production costs, increasing production capacity, and reducing etching steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to make the content of the present invention clearer and easier to understand, the content of the present invention will be described in detail below in conjunction with specific embodiments and accompanying drawings.

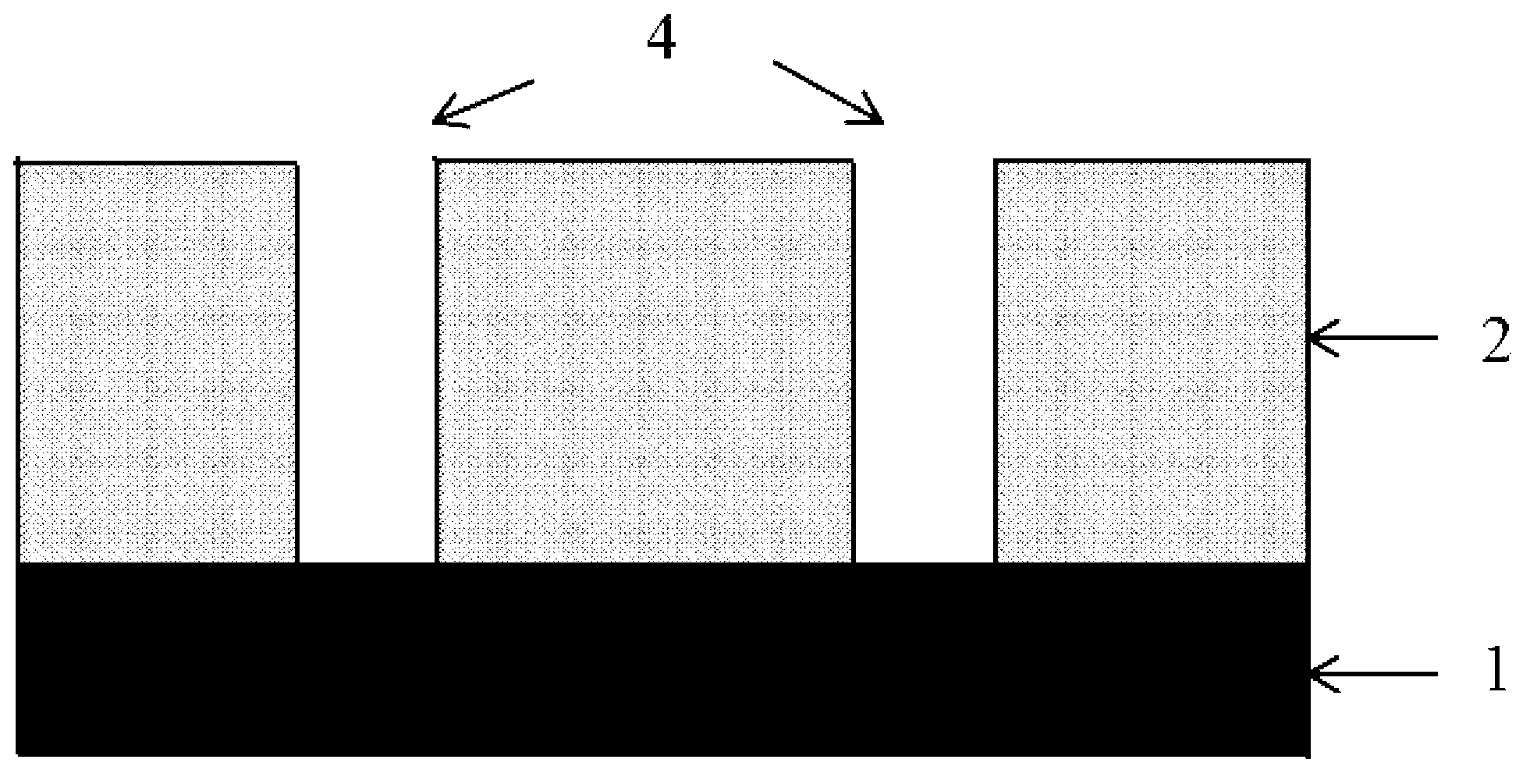

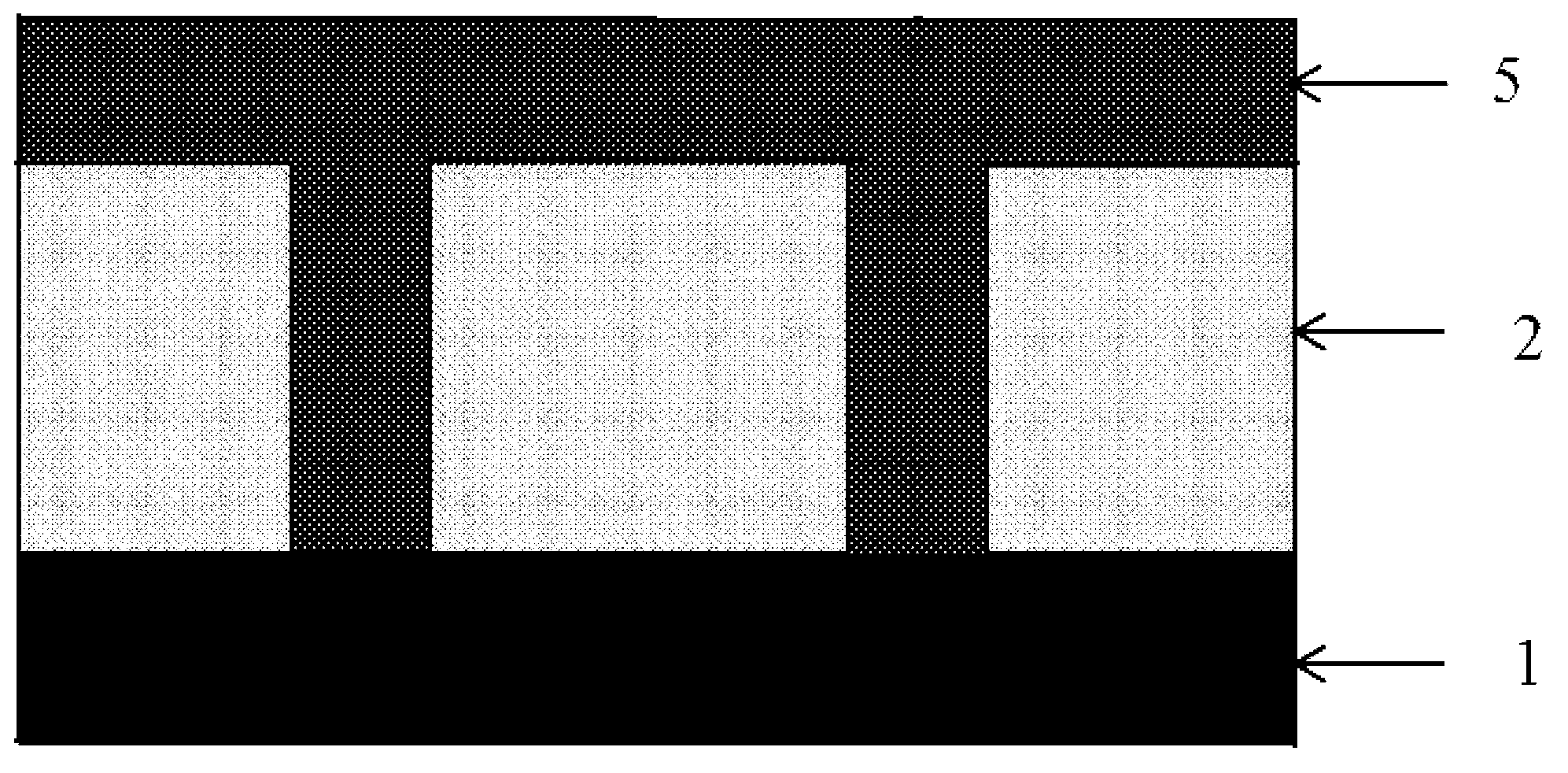

[0035] Figure 3A to Figure 3IA cross-sectional view schematically shows various steps of a via-first dual damascene copper interconnection method for reducing redundant metal coupling capacitance according to a preferred embodiment of the present invention. The via-first dual damascene copper interconnect method utilizes double exposure technology and formable hard film photoresist to reduce redundant metal coupling capacitance.

[0036] Specifically, as Figure 3A to Figure 3I As shown, according to the preferred embodiment of the present invention, the via-first dual damascene copper interconnection method for reducing redundant metal coupling capacitance includes:

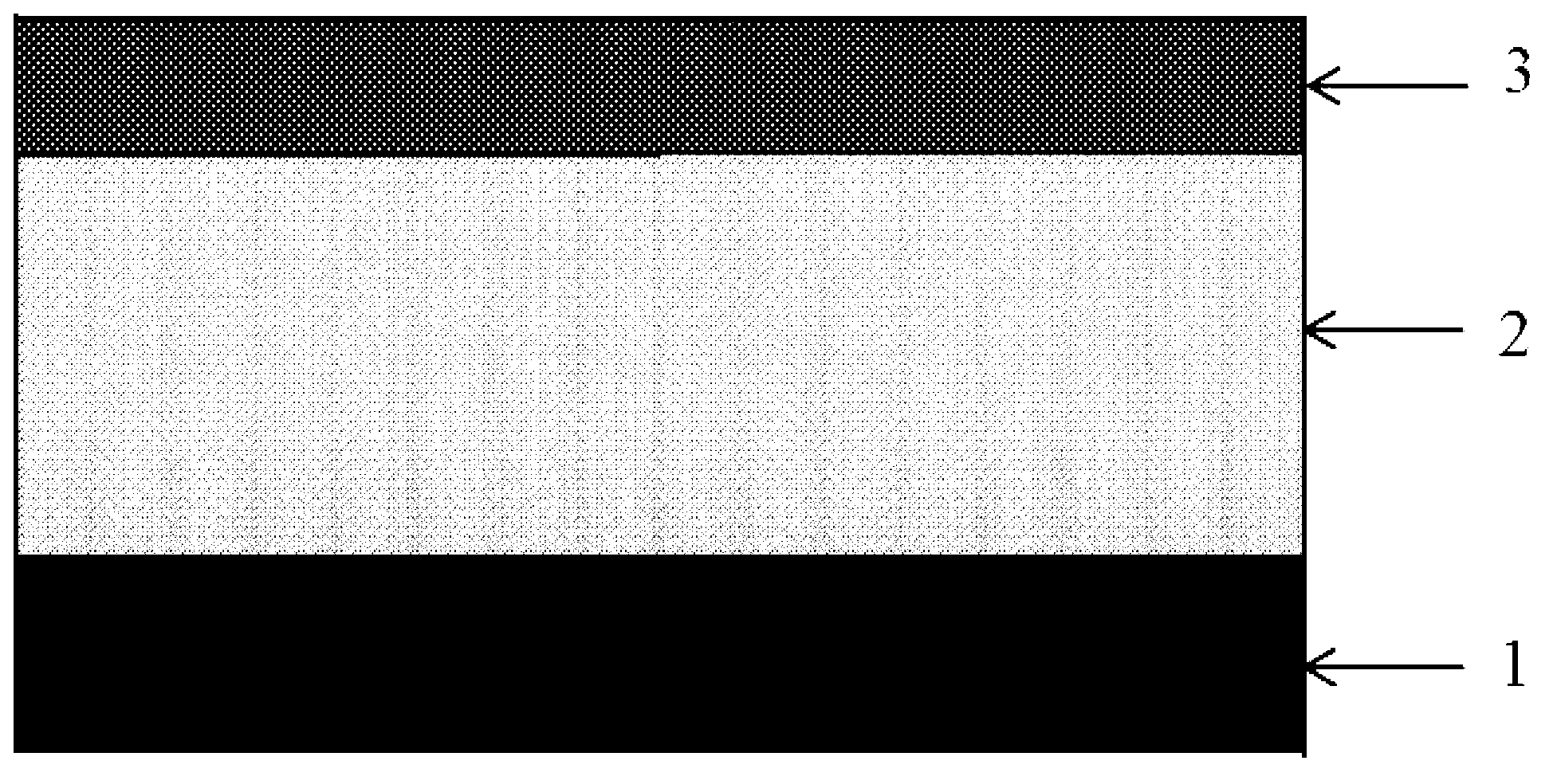

[0037] The first step: first deposit a dielectric layer 2 on the substrate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com