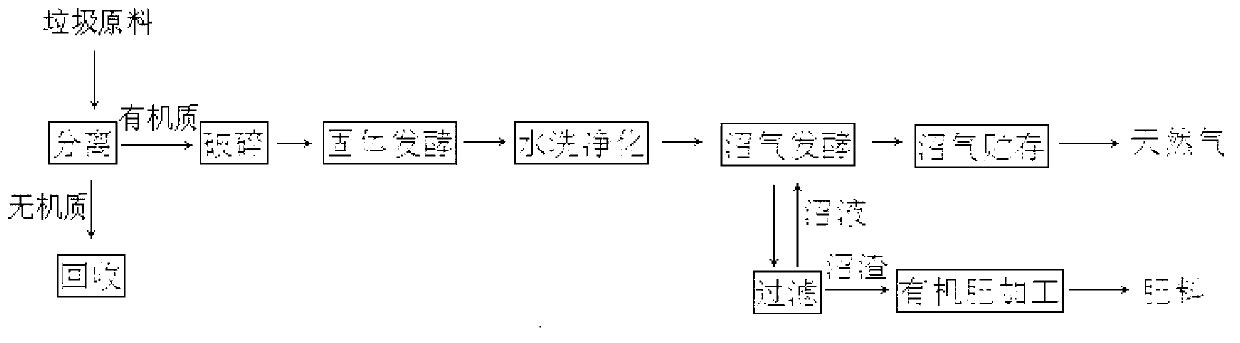

Urban living garbage treatment method

A technology of municipal solid waste and treatment method, which is applied in the field of waste treatment to achieve the effects of strong comprehensive performance, improved environmental protection effect and uniform particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

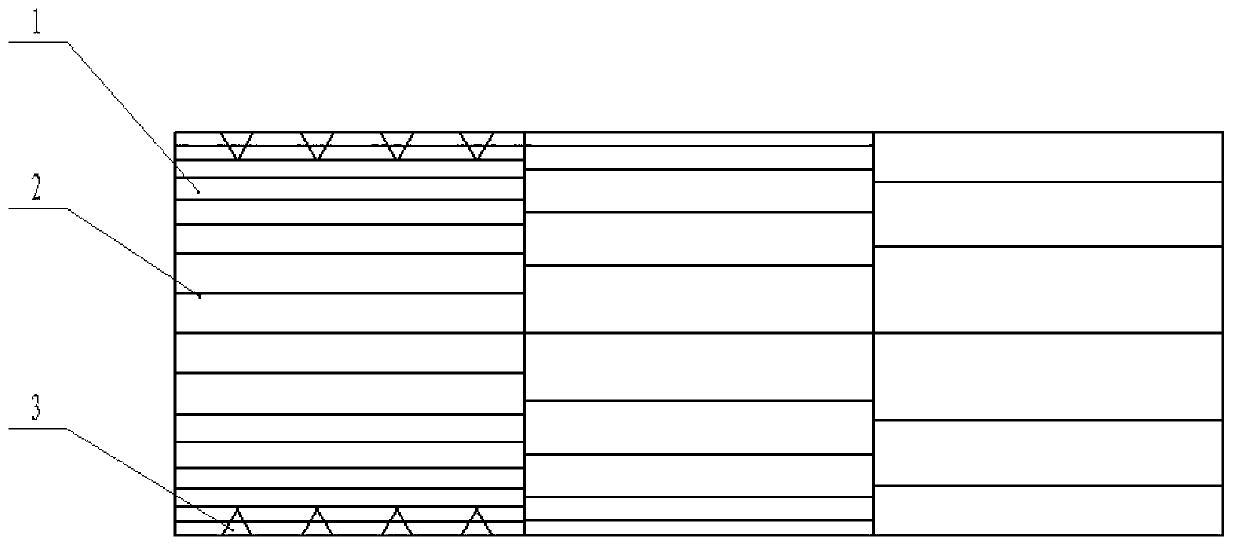

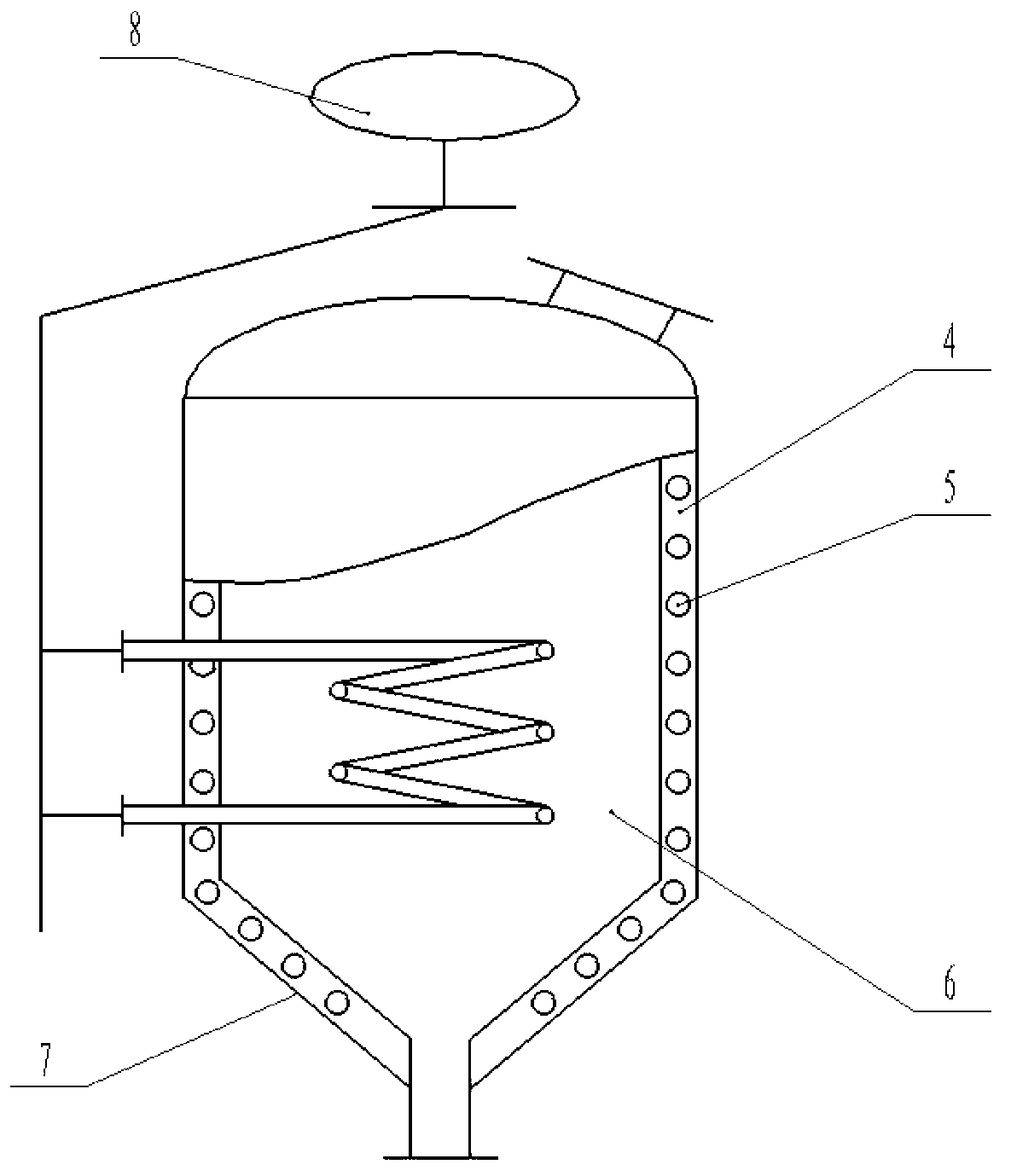

[0031] Municipal solid waste is transported in by a transport vehicle, and the transport vehicle unloads the waste on the drum sorter 1 . When the drum sorter 1 is working, the rotating speed is 8r / min, and the waste materials can be sorted into fermentable organic matter and non-fermentable inorganic matter. The barrel of the drum-shaped sorting machine 1 is squirrel-cage-shaped welded by steel bars 2. It is a three-stage sorting machine, and the gap between the steel bars 2 increases step by step. The gap between the steel bars 2 of the first-stage sorting machine is 6cm, and the blade 3 is set inside, which can effectively disassemble the garbage packaging bags during the sorting process, and sort out non-fermentable dusty garbage, waste batteries, and small pieces of waste. Glass and paper; the gap between the steel bars 2 of the second-stage sorting machine is 10cm, which can sort out waste plastics and shoes; the gap between the steel bars 2 of the third-stage sorting ma...

Embodiment 2

[0033] Municipal solid waste is transported in by a transport vehicle, and the transport vehicle unloads the waste on the drum sorter 1 . When the drum sorter 1 is working, the rotating speed is 10r / min, and the waste materials can be sorted into fermentable organic matter and non-fermentable inorganic matter. The barrel of the drum-shaped sorting machine 1 is squirrel-cage-shaped welded by steel bars 2. It is a three-stage sorting machine, and the gap between the steel bars 2 increases step by step. Drum sorting machine 1 steel bar 2 with a gap of 5cm, internally equipped with blade 3, which can effectively disassemble garbage packaging bags during the sorting process, and sort out non-fermentable dusty garbage, waste batteries, and small pieces of waste glass and paper; the second-stage steel bar 2 gap of the drum sorter 1 is 8cm, which can sort waste plastics and shoes; the third-stage steel bar 2 gap of the drum sorter 1 is 18cm, which can sort out Large pieces of waste g...

Embodiment 3

[0035]Municipal solid waste is transported in by a transport vehicle, and the transport vehicle unloads the waste on the drum sorter 1 . When the drum sorter 1 works, the rotating speed is 12r / min, and the waste materials can be sorted into fermentable organic matter and non-fermentable inorganic matter. The barrel of the drum-shaped sorting machine 1 is squirrel-cage-shaped welded by steel bars 2. It is a three-stage sorting machine, and the gap between the steel bars 2 increases step by step. The gap between the steel bars 2 of the first stage of the drum sorter 1 is 8cm, and the blade 3 is set inside, which can effectively disassemble the garbage packaging bags during the sorting process, and sort out non-fermentable dust garbage, waste batteries, Small pieces of waste glass and paper; the gap between the steel bars 2 of the second stage of the drum sorter 1 is 10cm, which can sort waste plastics and shoes; the gap between the 2 steel bars of the third pole of the drum sort...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com