Synchronizer combination toothed ring machining method and special die thereof

A processing method and technology of combining teeth, applied in forming tools, manufacturing tools, metal processing equipment, etc., can solve problems such as affecting processing accuracy, large equipment investment, operation errors, etc., to improve production efficiency and product accuracy, and solve production costs. , the effect of simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

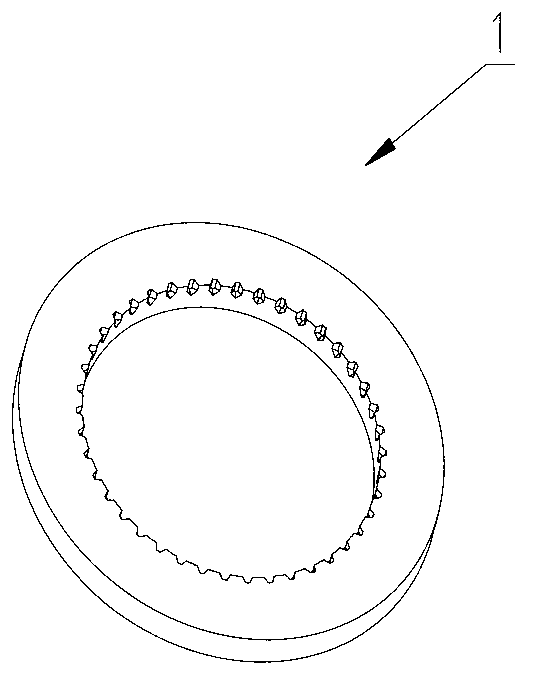

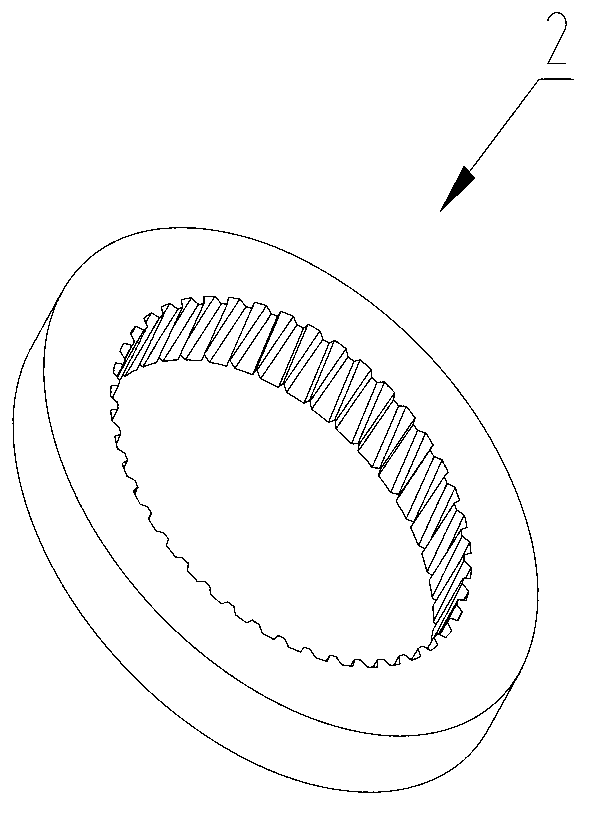

[0026] The core of the present invention is to provide a method for processing a synchronizer combined with a gear ring, which can improve the processing efficiency of a combined gear ring while meeting product design requirements and manufacturing capabilities, and the processing process is relatively simple, and the cost of processing equipment is relatively low. Low. Another core of the present invention is to provide a special mold for the above processing method.

[0027] In order to enable those skilled in the art to better understand the solution of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

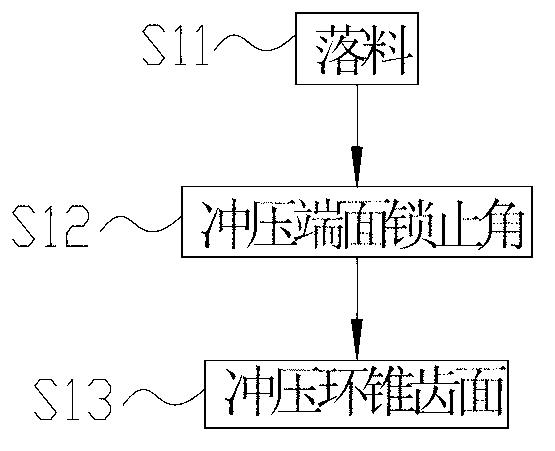

[0028] Please refer to figure 1 , figure 1 It is a flow chart of a specific embodiment of the method for processing a synchronizer combined with a ring gear provided by the present invention.

[0029] The present invention provides a method for processing a synchr...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap