Medical digital ink-jet printing paper

A digital inkjet and photographic paper technology, applied in the field of medical consumables, can solve the problems of difficult natural degradation, low clarity and gray scale, and high energy consumption, and reduce the use of precious metals and silver, clarity and gray scale. The effect of improving the speed and quickly stabilizing the image

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

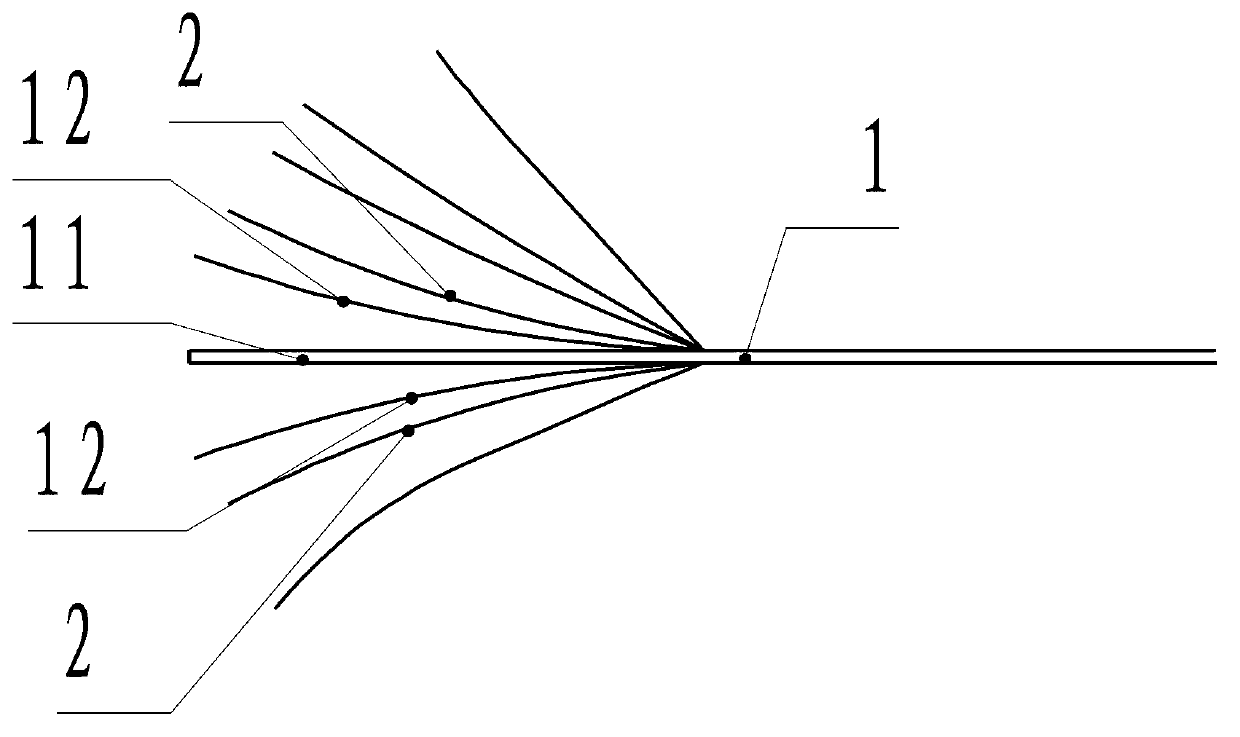

[0015] A kind of medical digital ink-jet photographic paper, comprising double-sided plastic-coated film-coated photographic paper backing paper 1, the surface of described backing paper is coated with paint coating 2, and described backing paper comprises base paper 11 of middle layer and coated The polyethylene coating 12 molded on the base paper surface, the thickness of the polyethylene coating on the front is 25 μm, the thickness of the polyethylene coating on the back is 10 μm, and the paint coating 2 on the front side of the base paper has 4 layers, with a total thickness of 45 μm , the paint coating on the reverse side has a total thickness of 10 μm. Described polyethylene film comprises 20 parts of polyethylenes by weight, the dicumyl oxide of 0.5 parts, the TiO of 0.5 parts 2 , the paint coating includes 20 parts by weight of nano-sized SiO 2 , 20 parts nanoscale CaCO 3 , 20 parts nanoscale TiO 2 , 20 parts nanoscale Al 2 o 3 , 1 part of PVA, 0.5 part of polyacr...

Embodiment 2

[0017] A kind of medical digital ink-jet photographic paper, comprising double-sided plastic-coated film-coated photographic paper backing paper 1, the surface of described backing paper is coated with paint coating 2, and described backing paper comprises base paper 11 of middle layer and coated The polyethylene coating 12 molded on the base paper surface, the thickness of the polyethylene coating on the front is 40 μm, the thickness of the polyethylene coating on the back is 30 μm, the paint coating 2 on the front side of the base paper has 3 layers, and the total thickness is 30 μm , the paint coating on the reverse side has 3 layers with a total thickness of 28 μm. Described polyethylene film comprises the polyethylene of 25 parts by weight, the dicumyl oxide of 0.8 part, the TiO of 1.5 parts 2 , the paint coating includes 25 parts by weight of nano-sized SiO 2 , 25 parts nanoscale CaCO 3 , 25 parts nanoscale TiO 2 , 25 parts nanoscale Al 2 o 3 , 2 parts of PVA, 1 par...

Embodiment 3

[0019] A kind of medical digital ink-jet photographic paper, comprising double-sided plastic-coated film-coated photographic paper backing paper 1, the surface of described backing paper is coated with paint coating 2, and described backing paper comprises base paper 11 of middle layer and coated The polyethylene coating 12 molded on the base paper surface, the thickness of the polyethylene coating on the front is 30 μm, the thickness of the polyethylene coating on the back is 20 μm, the paint coating 2 on the front side of the base paper has 2 layers, and the total thickness is 35 μm , the paint coating on the reverse side has a layer thickness of 10 μm. Described polyethylene film comprises the polyethylene of 22 parts by weight, the dicumyl oxide of 0.6 part, the TiO of 1 part 2 , the paint coating includes 22 parts by weight of nano-scale SiO 2 , 22 parts nanoscale CaCO 3 , 22 parts nanoscale TiO 2 , 22 parts of nanoscale Al 2 o 3 , 1.5 parts of PVA, 0.8 parts of poly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com