Glutamic acid synergistic high-tower compound fertilizer and production method thereof

A glutamic acid and compound fertilizer technology, applied in fertilization equipment, fertilizer mixture, application, etc., can solve the problems of difficult large-scale promotion and application, high production cost, high price, etc., and achieve the effect of simple and diverse methods of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

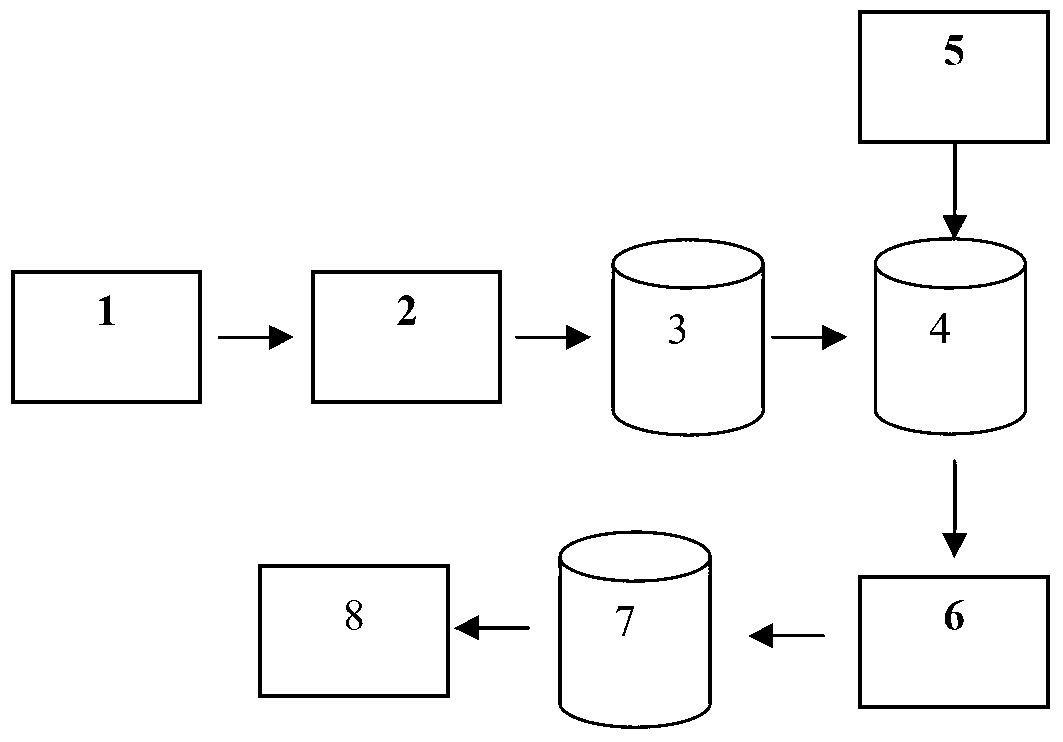

Method used

Image

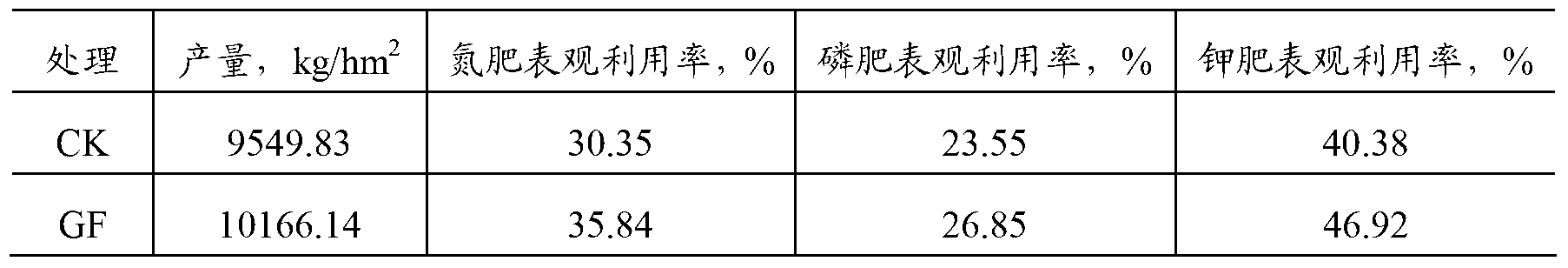

Examples

Embodiment 1

[0108] Example 1: Production of glutamic acid synergistic high-tower compound fertilizer of the present invention

[0109] The implementation steps of this embodiment are as follows:

[0110] A. Preparation of glutamic acid synergist:

[0111] Prepare 20% sodium glutamate solution with a concentration by weight, which is glutamate synergist A;

[0112] B. Preparation of glutamic acid-urea melt

[0113] Using the metering pump sold by Changzhou Xiaoyuan Machinery Co., Ltd. under the trade name JYM-I metering pump, add the glutamic acid synergist A and urea obtained in step A to the conventional urea production process at a weight ratio of 2:65. In the urea melting tank on the pellet tower, it is fully melted at a temperature of 125°C to obtain a glutamic acid-urea melt;

[0114] C. Other fertilizer pretreatment

[0115] Diammonium phosphate, potassium sulfate and calcium carbonate powder are respectively pulverized to a fineness of 30 mesh or more, and then preheated to a temperature of 1...

Embodiment 2

[0120] Example 2: Production of glutamic acid synergistic high-tower compound fertilizer of the present invention

[0121] The implementation steps of this embodiment are as follows:

[0122] A. Preparation of glutamic acid synergist:

[0123] Mix 10% sodium hydroxide solution by weight with glutamic acid in a weight ratio of 1.8:1, and the resulting solution is glutamic acid synergist B;

[0124] B. Preparation of glutamic acid-urea melt

[0125] Using the metering pump sold by Changzhou Xiaoyuan Machinery Co., Ltd. under the trade name JYM-II metering pump, add the glutamate synergist B obtained in step A to urea in a weight ratio of 5:50 to the conventional urea production process. In the urea melting tank on the pellet tower, it is fully melted at a temperature of 115°C to obtain a glutamic acid-urea melt;

[0126] C. Other fertilizer pretreatment

[0127] Crush the monoammonium phosphate, potassium chloride and dolomite to a fineness of more than 30 mesh, and then preheat to a tempe...

Embodiment 3

[0132] Example 3: Production of glutamic acid synergistic high-tower compound fertilizer of the present invention

[0133] The implementation steps of this embodiment are as follows:

[0134] A. Preparation of glutamic acid synergist:

[0135] Prepare a 10% sodium glutamate solution with a concentration by weight, which is glutamate synergist A;

[0136] B. Preparation of glutamic acid-urea melt

[0137] Using the metering pump sold by Changzhou Xiaoyuan Machinery Co., Ltd. under the trade name JJM-II plunger metering pump, add the glutamic acid synergist A obtained in step A to urea in a weight ratio of 3:70 In the urea melting tank located on the prilling tower of the conventional urea production process, it is fully melted at a temperature of 105°C to obtain a glutamic acid-urea melt;

[0138] C. Other fertilizer pretreatment

[0139] Diammonium phosphate, potassium chloride and calcium carbonate are respectively pulverized to a fineness of 30 mesh or more, and then preheated to a tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com