High temperature resistance and low dielectric glass cloth honeycomb sandwich adhesive and preparation method thereof

A technology of glass cloth and low dielectric, applied in the direction of adhesives, non-polymer adhesive additives, adhesive types, etc., can solve the problems of unsatisfactory process performance and low temperature resistance level of sandwich adhesives

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

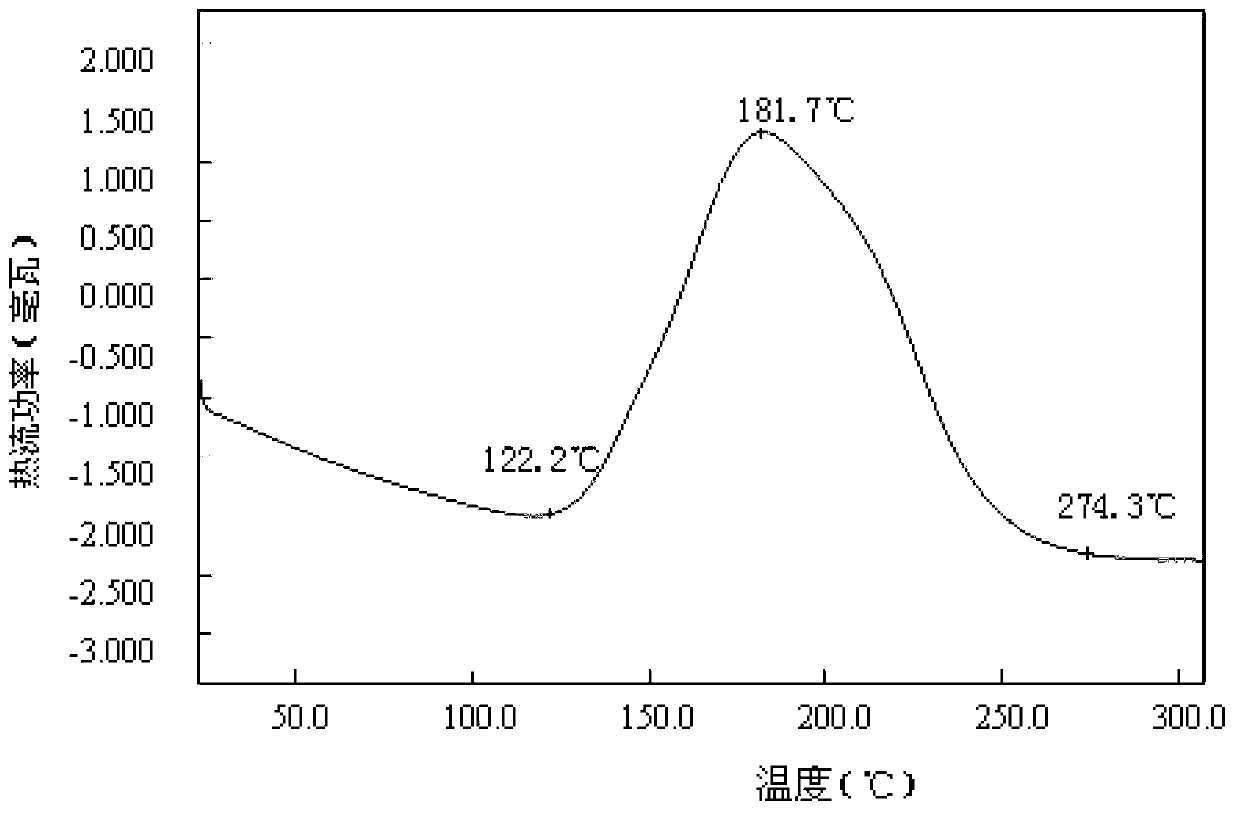

Image

Examples

specific Embodiment approach 2

[0023] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the high temperature resistant low dielectric glass cloth honeycomb sandwich adhesive consists of 100 parts by mass of main resin, 20-25 parts of modified resin, 25-25 parts It is prepared by 30 parts of rubber elastic toughening agent, 3-5 parts of inorganic filler, 2-3 parts of silane coupling agent and 220-240 parts of solvent. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0024] Specific embodiment three: what this embodiment is different from specific embodiment one or two is: main body resin is made of novolak type cyanate, bisphenol A type cyanate and bisphenol E type cyanate, wherein novolak type cyanate The mass ratio of ester, bisphenol A cyanate and bisphenol E cyanate is 5:4:1. Others are the same as in the first or second embodiment.

specific Embodiment approach 4

[0025] Specific embodiment four: what this embodiment is different from specific embodiment one or two is: modified resin is prepared by prepolymerization method by double horse resin and modifier, and wherein the mass ratio of double horse resin and modifier is 4: 3; and the double horse resin is composed of 4,4'-diaminodiphenylmethane type double horse resin and BMT type double horse resin, 4,4'-diaminodiphenylmethane type double horse resin and BMT type double horse resin The mass ratio is 2:1; the modifier consists of allyl bisphenol A, allyl ether novolac resin and vinyl nitrile rubber, allyl bisphenol A, allyl ether novolac resin and vinyl The mass ratio of nitrile rubber is 5:3:2. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Normal temperature shear strength | aaaaa | aaaaa |

| Shear strength | aaaaa | aaaaa |

| Shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com