Coal fuel sulfur-fixation burning accelerant and preparation method thereof

A combustion aid and sulfur-fixing agent technology, applied in the field of environmental protection, can solve the problems of high cost, single component, unfriendly environment, etc., and achieve the effect of low corrosion of equipment, high degree of dispersion, and simple and cheap raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Weigh potassium nitrate 1.5kg, potassium bromate 0.5kg, manganese dioxide 0.5kg, iron red 0.2kg, cerium nitrate 0.1kg, nickel sulfate 0.1kg, potassium permanganate 0.5kg, borax 0.5kg, slaked lime 1.0kg, bentonite 5.1kg . Grind to 80-100μm respectively, then mix and stir evenly. Dissolve in water at a weight ratio of 2.5:10, and evenly spray on 4000 kg of low-quality coal. Then burn in the furnace.

Embodiment 2

[0031] Example 2 Research on the application performance of sulfur-fixed combustion accelerant

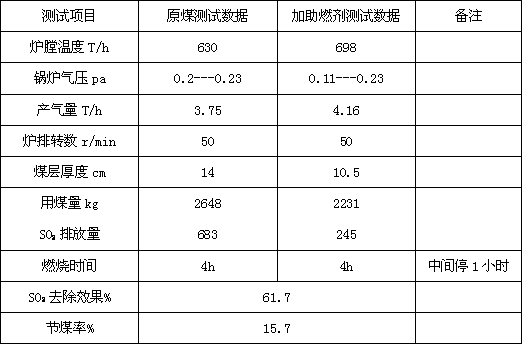

[0032] The sulfur-fixing combustion accelerant prepared in embodiment 1 is joined in plate furnace, carries out combustion test, and data is as follows:

[0033] The performance of the sulfur-fixed combustion accelerant prepared by the embodiment 1 of table 1

[0034]

[0035] From the data in Table 1, it can be seen that after adding high-efficiency sulfur-fixing combustion accelerant, SO 2 Emissions are 61.7%. The comprehensive coal saving rate is 15.7%. Therefore, the high-efficiency sulfur-fixing combustion accelerant of the present invention has easy-to-obtain raw materials, simple processing, no emission, little corrosion, strong operability and obvious effect. Show great industrial application value.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com