Rare earth-containing high-strength atmospheric corrosion-resistant seamless steel pipe and production method thereof

An atmospheric corrosion-resistant, seamless steel pipe technology, applied in the direction of pipes, rigid pipes, pipes/pipe joints/fittings, etc. problem, to achieve the effect of excellent atmospheric corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

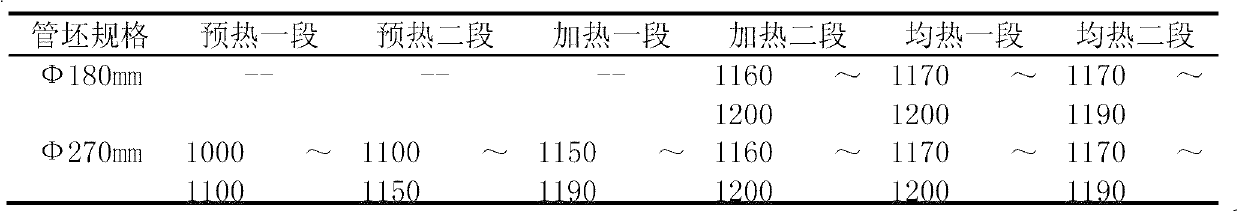

Examples

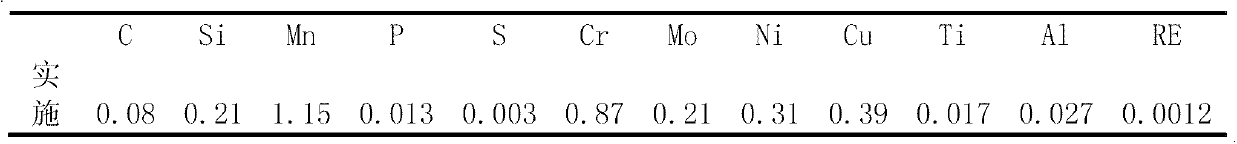

Embodiment 1

[0041] Raw materials by weight percentage are: 90% of blast furnace molten iron and 10% of high-quality steel scrap.

[0042] The sequence of the production process is: molten iron pretreatment→top-bottom double-blowing converter smelting→LF furnace refining→VD vacuum treatment→circular casting→cutting→pipe heating→piercing→continuous rolling→reheating→sizing→cooling→sawing Cutting→heat treatment→straightening→flaw detection.

[0043] The specific production process is briefly described as follows:

[0044] 90 tons of blast furnace molten iron was pretreated with "metal magnesium powder" for desulfurization and deoxidation, so that the S content in the molten iron was reduced to (weight percent) below 0.010%;

[0045] Mix the 90 tons of pretreated molten iron into a 100-ton top-bottom combined blown converter, add 10 tons of high-quality steel scrap, and then use the single slag process for smelting. The final slag basicity is controlled at 3.0, and silicon Manganese, ferrom...

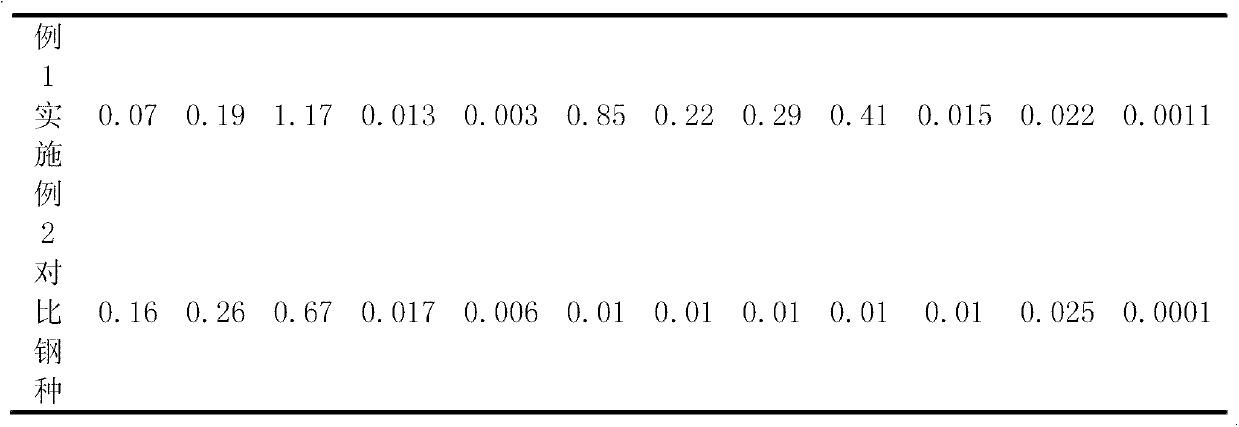

Embodiment 2

[0064] The ratio of raw materials, production process, etc. and other technical indicators of Example 2 are the same as those of Example 1, the difference is the chemical composition content and straightening temperature of the tube failure, and the chemical composition test results (weight %) are shown in Table 2 :

[0065] The straightening temperature of the steel pipe is 522°C, and the residual stress of the steel pipe measured by the circumcision method is 21MPa

PUM

| Property | Measurement | Unit |

|---|---|---|

| Residual stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com