Method for analogue measuring cementing strength and anti-fluid channeling capacity of oil well cement

A cementing strength, oil well cement technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of neglecting the interface hydraulic cementation, not taking into account the weight loss of the cement slurry, large evaluation errors, etc., and achieving the effect of convenient and easy-to-learn operation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Further illustrate the present invention below in conjunction with accompanying drawing.

[0025] The method for simulating and measuring the bonding strength and anti-channeling ability of the oil well cement sheath includes the following steps in sequence:

[0026] (1) Process the simulated rock sample or the real rock sample taken from the formation to make a core that meets the test size requirements, and drill a "channel (narrow slot)" with a certain height and diameter in the middle of the core. "Simulate the seepage channel of formation fluid;

[0027] (2) Install the cement stone test mold, inject cement slurry into the cement stone test mold and the annulus of the core, and put it into the curing kettle for heating and pressure curing;

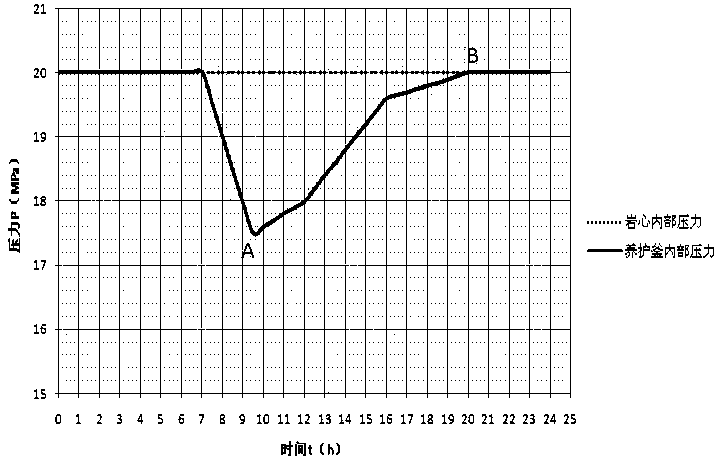

[0028] (3) Assuming that the pressure of the simulated formation is 20MPa, the initial pressure of the cement slurry column after injecting the cement slurry is 20MPa, that is, the cement slurry is cured in the high-temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com