Bitter gourd dry product with high vitamin C content and preparation method thereof

A vitamin and bitter gourd technology, applied in the field of preparation of dried bitter gourd products, can solve the problems of high production cost, low economic benefit, long duration, etc., and achieve the effects of improving efficiency, high taste preference, and high retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

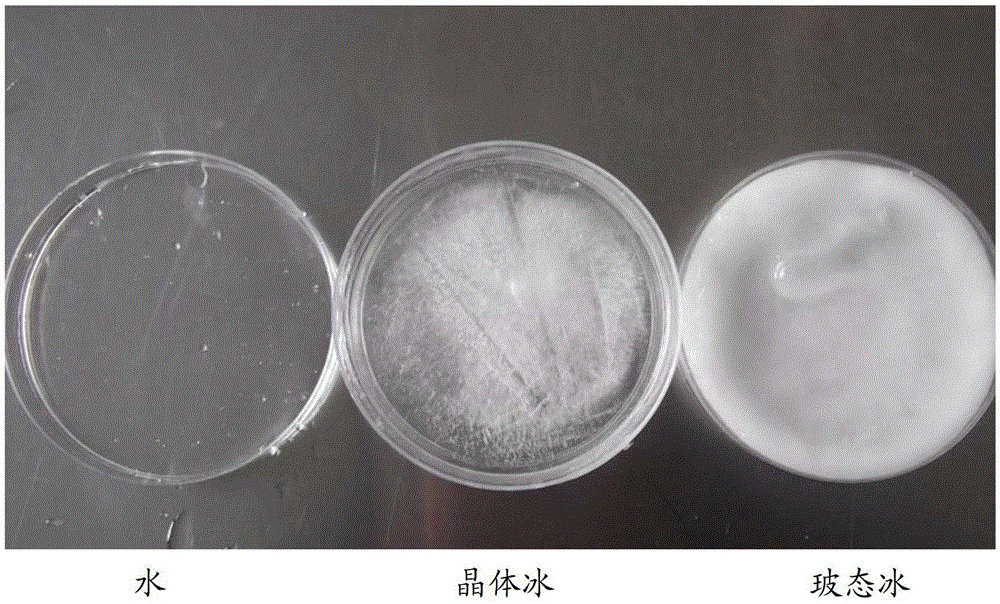

[0079] In a specific embodiment herein, a method for preparing dry bitter gourd with high vitamin C content is provided, the method includes the step of providing fresh bitter gourd at first, and cooling the fresh bitter gourd by an average of more than 20°C per minute, preferably 30°C More than °C, preferably more than 40°C, preferably more than 60°C, preferably more than 90°C, the step of cooling at a cooling rate; and the sublimation step of sublimating the fresh balsam pear through the cooling step.

[0080] According to the above description, the fresh bitter gourd is physically treated fresh bitter gourd. The step of providing fresh bitter gourd is to obtain fresh bitter gourd raw materials, or perform simple pretreatment on fresh bitter gourd raw materials, such as washing, slicing or granulating, etc., to obtain fresh bitter gourd slices or granules of bitter gourd with a certain shape and size .

[0081]Herein, there is no need to carry out other pretreatment steps o...

Embodiment 1

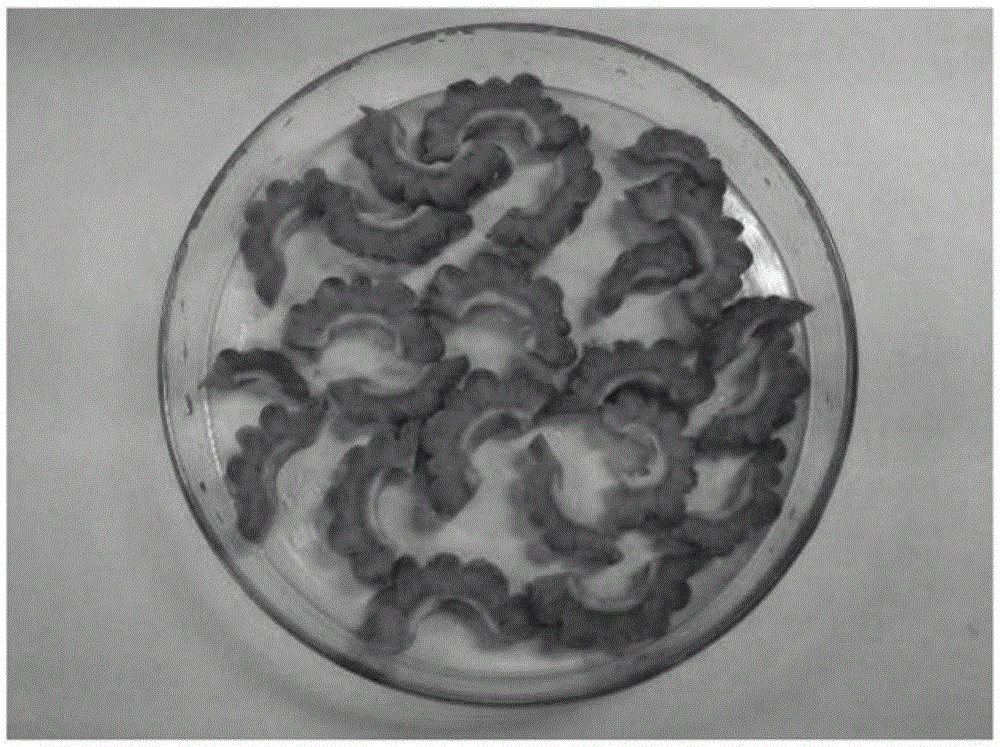

[0158] Embodiment 1 prepares balsam pear dry product 1

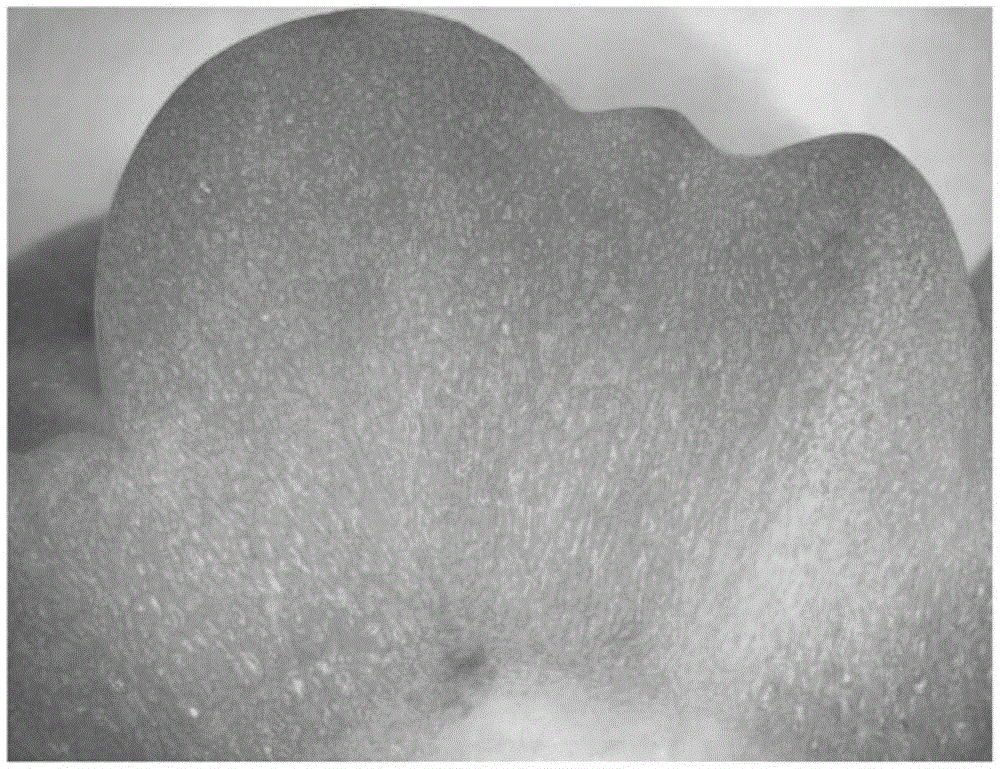

[0159] Choose fresh bitter gourd purchased from supermarkets as the raw material for dry products. Wash and drain the fresh bitter gourd and cut into slices. Each slice of bitter gourd is about 0.5cm thick and 3~5cm long. The photos of the obtained bitter gourd slices are as follows figure 1 shown. Then immediately put it in a plastic jar, about two-thirds full. Carefully put the plastic tank into the bucket of the liquid nitrogen tank, let the bucket slowly enter the liquid nitrogen, wait for 5 minutes after being completely filled with liquid nitrogen, then take it out and put it into a freeze dryer (LGJ-10 freeze dryer, Beijing Songyuan Huaxing Technology Development Co., Ltd.) drying, drying more than 60 hours. After drying, the dried bitter gourd was taken out to obtain the dried bitter gourd shown in FIG. 3 .

Embodiment 2

[0160] Embodiment 2 prepares balsam pear dry product 2

[0161] Choose fresh bitter gourd purchased from supermarkets as the raw material for dry products. Wash and drain the fresh bitter gourd and cut into slices, each slice is about 0.5cm thick and 3~5cm long. Then spray liquid nitrogen to the balsam pear slices, spray for 5 minutes, put the balsam pear slices into a freeze dryer (LGJ-10 freeze dryer, Beijing Songyuan Huaxing Technology Development Co., Ltd.) after spraying and dry for more than 60 hours . After drying, the dried bitter gourd was taken out to obtain the dried bitter gourd shown in FIG. 5 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com