Spouted fluidized bed reactor and polymer preparation method

A technology of spouted fluidized bed and reactor, applied in the direction of chemical instruments and methods, chemical/physical processes, etc., can solve problems such as aggravation of agglomeration, defluidization, enhancement, etc., to achieve enhanced movement activity and enhanced crushing Effect, strengthen the effect of impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

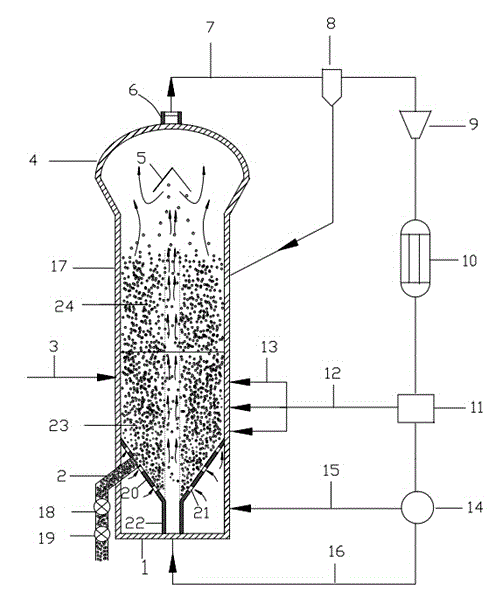

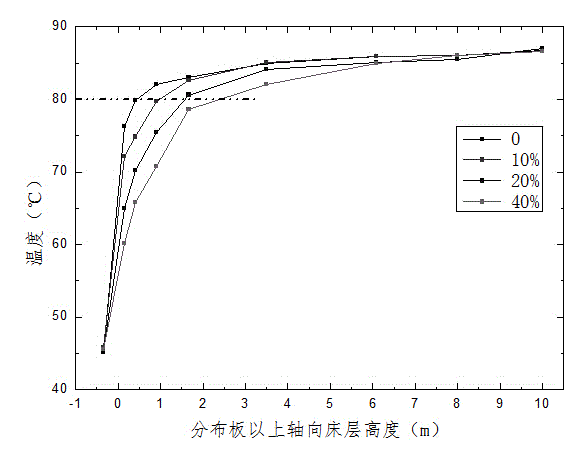

[0038] The reaction cycle gas flows out from the gas outlet 6 at the top of the reactor, and the entrained fine powder particles are separated by the cyclone separator 8, and the cycle gas has a sufficient pressure head through the compressor 9, and then the cycle gas is cooled by the heat exchanger 10, and the cooling The gas-liquid mixed stream at the outlet of the device is divided into two parts, the liquid phase stream and the gas phase stream, through the gas-liquid separator 11, and the liquid phase stream passes through the pipeline 12 and the liquid injector 13 arranged at the lower position of the spouted fluidized bed Two reaction zones are formed in the reactor bed, the bottom is the G-L-S three-phase fluidized zone with liquid phase, and the upper part is the G-S two-phase fluidized zone with no liquid phase. The gaseous phase stream is divided into a jet gas stream 16 and an auxiliary gas stream 15 by a splitter 14, the stream 16 enters the injection zone thro...

Embodiment 2

[0041] The same spouted fluidized bed polymerization reactor as in Example 1 was used to prepare polyolefin. It is mainly to change the following conditions to realize the regulation and control of the molecular weight distribution of the product. By adjusting the temperature at the outlet of the heat exchanger, the mass fraction of the liquid phase in the gas-liquid mixture was controlled at 60%. Combined with controlling the amount of catalyst added, the average temperature of the bottom G-L-S three-phase region was maintained at 70°C, while the average temperature of the upper G-S three-phase region was maintained at 88°C. The pressure in the reaction zone was adjusted to 2.1 MPa.

[0042] After the above reaction process was carried out for 6 hours, the polyethylene particles were taken out through the pipeline 2, and the obtained polyethylene particles were analyzed through a gel permeation chromatography column, and the results are shown in Table 1.

Embodiment 3

[0044] The same spouted fluidized bed polymerization reactor as in Example 1 was used to prepare polyolefin. By adjusting the temperature at the outlet of the heat exchanger, the mass fraction of the liquid phase in the gas-liquid mixture is controlled at 70%. Combined with controlling the amount of catalyst added, the average temperature of the bottom G-L-S three-phase region was maintained at 67°C, while the average temperature of the upper G-S three-phase region was maintained at 90°C. The pressure in the reaction zone was adjusted to 2.1 MPa.

[0045] After the above reaction process was carried out for 6 hours, the polyethylene particles were taken out through the pipeline 2, and the obtained polyethylene particles were analyzed through a gel permeation chromatography column, and the results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com