Rapid synthetic method of polycrystalline raw materials of gallium selenide and doped series of gallium selenide

A synthesis method and technology of gallium selenide are applied in the field of rapid synthesis of gallium selenide and its doped series polycrystalline raw materials, and can solve the problems of high vapor pressure of selenium element, slow heating process, easy to exceed pressure resistance, etc. The effect of good uniformity, fast synthesis rate and large amount of single synthesis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1: The synthesis of gallium selenide polycrystalline raw material is carried out according to the following steps:

[0034] ①Clean and dry the synthetic crucible made of quartz with deionized water, and coat the surface of the crucible with a suitable carbon film layer;

[0035] ②Choose gallium and selenium with a purity of 99.999%, and mix them according to the ratio of 1:1, totaling 400g, put the reaction raw materials into a quartz crucible, and evacuate to 10 -2 Pa sealed;

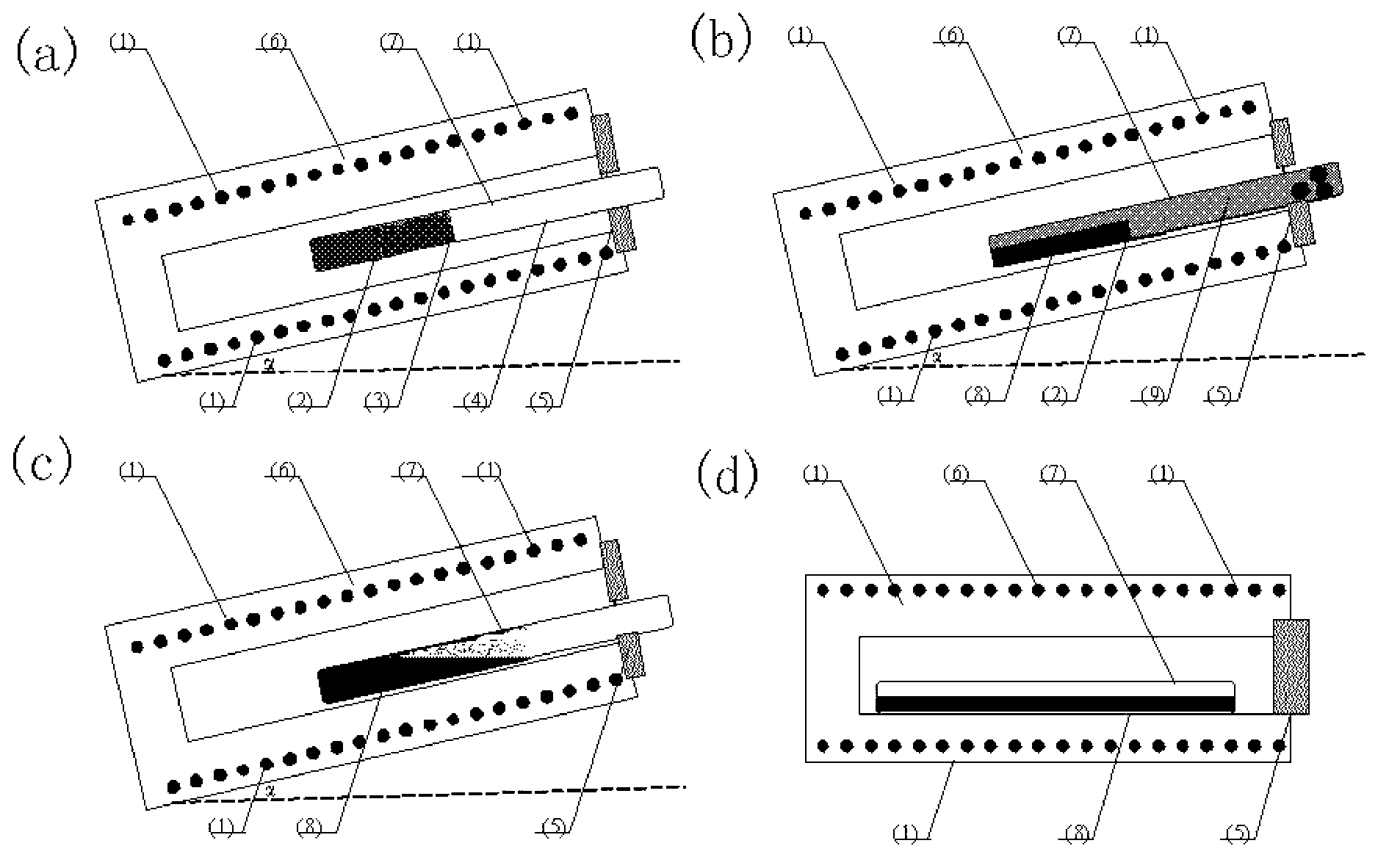

[0036] ③Put 80% of the sealed quartz crucible into the resistance synthesis furnace, plug the contact part of the furnace mouth with high-temperature refractory cotton above 1200°C, and expose the remaining part at the outer end of the synthesis furnace. The angle between the other end of the furnace body and the ground is 15°, as shown in the schematic diagram figure 1 as shown in a;

[0037] ④Quickly raise the temperature of the synthesis furnace to 880°C, and then raise the fina...

Embodiment 2

[0040] Embodiment 2: The synthesis of gallium selenide polycrystalline raw material is carried out as follows:

[0041] ①Clean and dry the synthetic crucible made of quartz with deionized water, and coat the surface of the crucible with a suitable carbon film layer;

[0042]②Choose gallium and selenium with a purity of 99.999%, and mix them according to the ratio of 1:1, totaling 400g, put the reaction raw materials into a quartz crucible, and evacuate to 10 -3 Pa sealed;

[0043] ③Put 95% of the sealed quartz crucible into the resistance synthesis furnace, plug the contact part of the furnace mouth with high-temperature refractory cotton above 1200°C, and expose the rest at the outer end of the synthesis furnace. The angle between the other end of the furnace body and the ground is 5°, as shown in the schematic diagram figure 1 as shown in a;

[0044] ④Quickly raise the temperature of the synthesis furnace to 860°C, then raise the final temperature of the furnace body to 9...

Embodiment 3

[0047] Embodiment 3: The synthesis of gallium selenide doped cadmium polycrystalline raw material is carried out according to the following steps:

[0048] ①Clean and dry the synthetic crucible made of quartz with deionized water, and coat the surface of the crucible with a suitable carbon film layer;

[0049] ②Choose gallium, selenium, and cadmium with a purity of 99.999%, and mix them according to the ratio of 0.98:1:0.02, totaling 400g, put the reaction raw materials into a quartz crucible, and evacuate to 10 -2 Pa sealed;

[0050] ③Put 90% of the sealed quartz crucible into the resistance synthesis furnace, plug the contact part of the furnace mouth with high-temperature refractory cotton above 1200°C, and expose the rest at the outer end of the synthesis furnace. The angle between the other end of the furnace body and the ground is 10°, as shown in the schematic diagram figure 1 as shown in a;

[0051] ④Quickly raise the temperature of the synthesis furnace to 870°C, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com