Method for removing metal ion impurities in aluminium chloride solution by multistage resin columns

A technology of resin column and aluminum chloride is applied in the field of multi-stage resin column processing aluminum chloride solution to remove iron, calcium and magnesium ions, and can solve the problems of inappropriate large-scale production, no impurity removal method, complicated process and the like, To achieve the effect of good impurity removal, easy control of production process and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

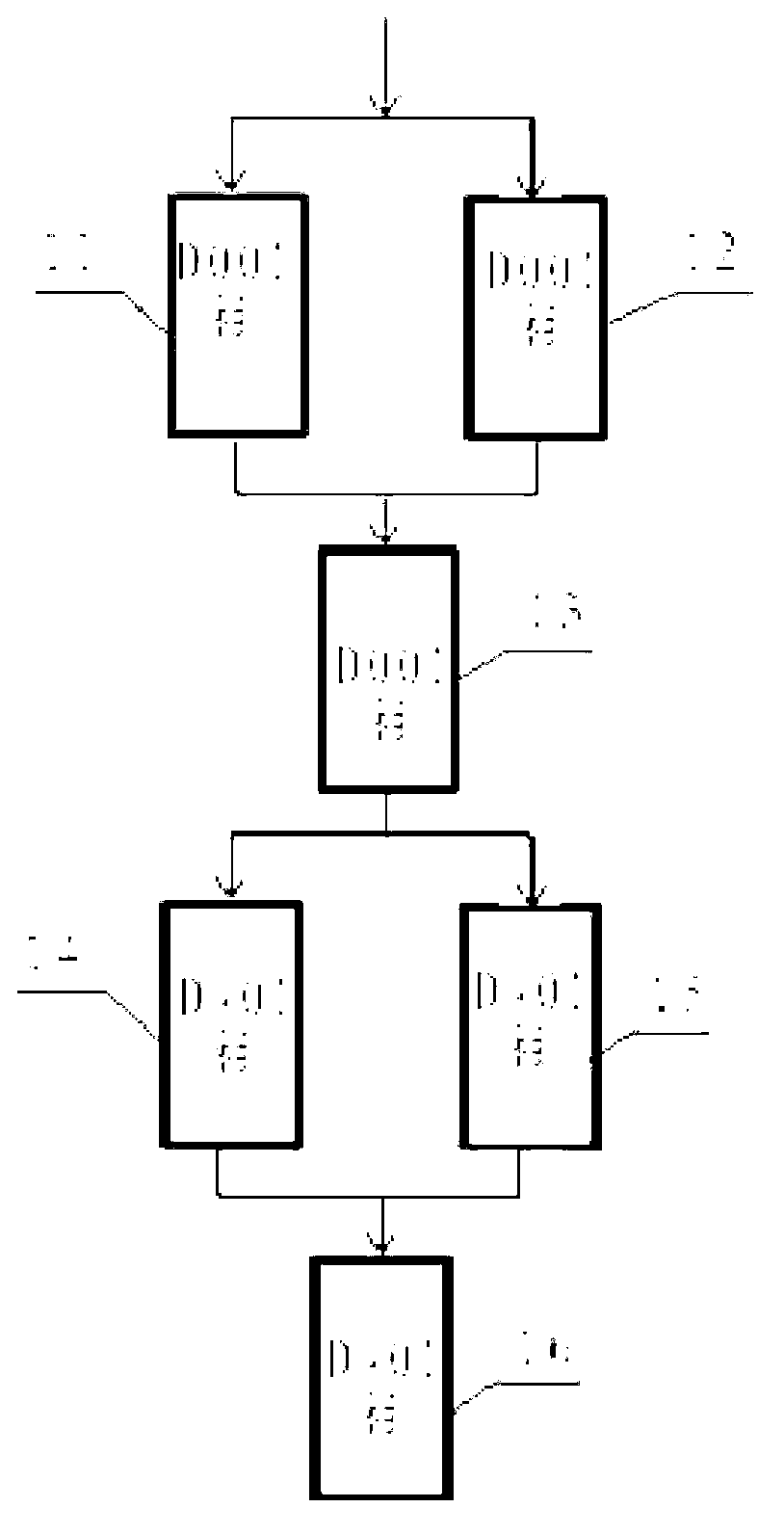

[0045] Contains 95 grams / liter of aluminum (calculated as alumina), 1.4 grams / liter of iron (calculated as iron oxide), 1.7 grams / liter of calcium (calculated as calcium oxide), and 1.1 grams / liter of magnesium (calculated as magnesium oxide) Measure) the aluminum chloride solution, adjust the pH value to 1.5 with hydrochloric acid solution, heat the temperature to 69°C, and press it into such as figure 1 In the multistage resin column group shown, wherein resin column 11, 12 and 13 are equipped with D001 type cation exchange resin, resin column 14, 15 and 16 are equipped with D401 type chelating resin, the resin loading capacity in each resin column 20ml respectively, and the diameter-to-height ratio of each resin column is 0.6:1. The aluminum chloride solution is processed by a downstream column method, and the incoming flow rate of the aluminum chloride solution is 40ml / hour.

[0046] After the impurity removal treatment, the obtained refined aluminum chloride solution was...

Embodiment 2

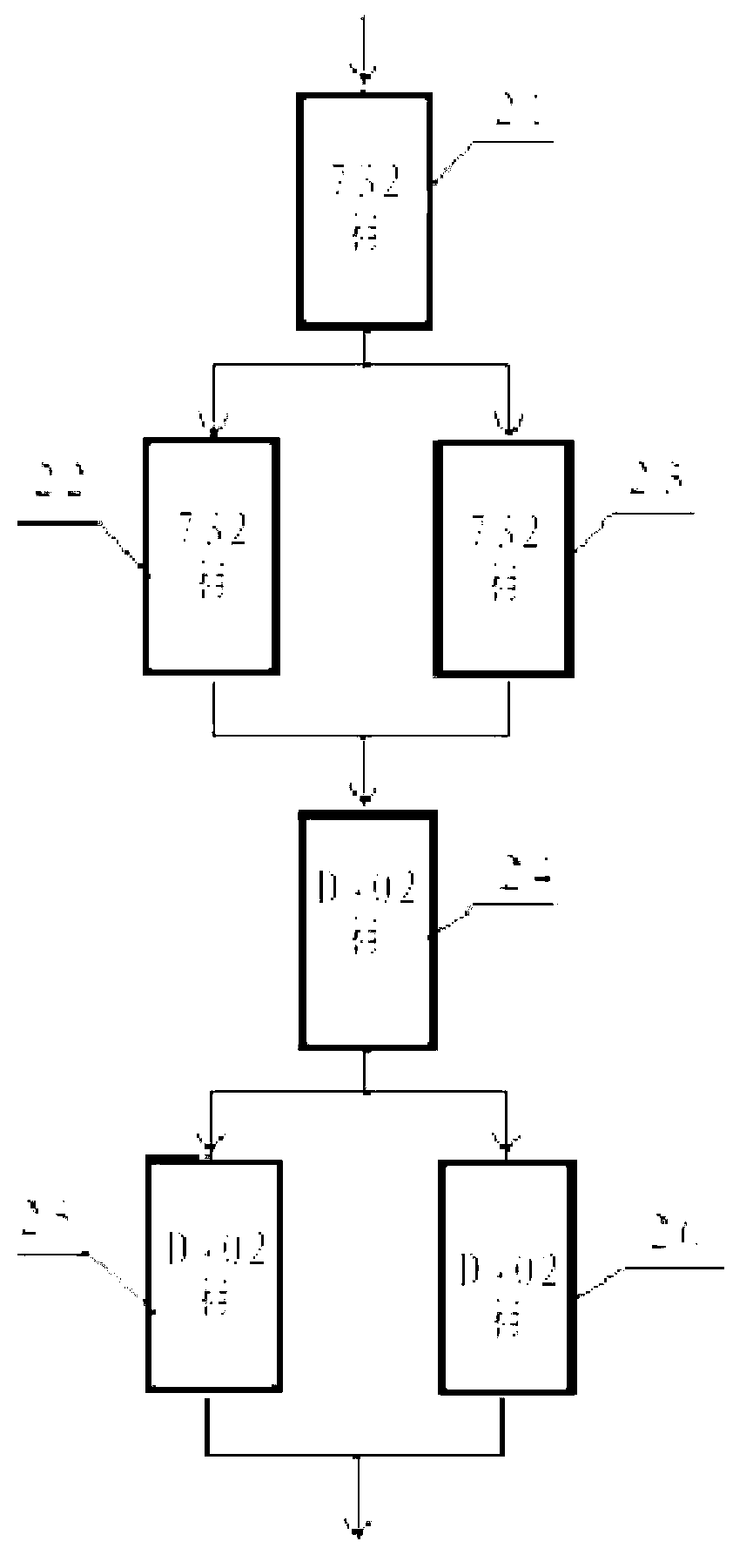

[0049] Contains 85 g / L of aluminum (calculated as alumina), 1.8 g / L of iron (calculated as iron oxide), 1.3 g / L of calcium (calculated as calcium oxide), and 1.4 g / L of magnesium (calculated as magnesium oxide) Calculate the aluminum chloride solution, adjust the pH value to 1.3 with hydrochloric acid solution, heat the temperature to 73°C, and press it into such as figure 2 In the shown multi-stage resin column group, the resin columns 21, 22 and 23 are equipped with 732 type cation exchange resin, and the resin columns 24, 25 and 26 are equipped with D402 type chelating resin. The diameter-to-height ratio of resin columns 21 and 24 is 1.8:1, and the resin loading capacity is 40 ml respectively; the diameter-height ratio of resin columns 22, 23, 25 and 26 is 0.6:1, and the resin loading capacity is 20 ml respectively. The aluminum chloride solution is processed by passing through the column method in parallel, and the incoming flow rate of the aluminum chloride solution is 6...

Embodiment 3

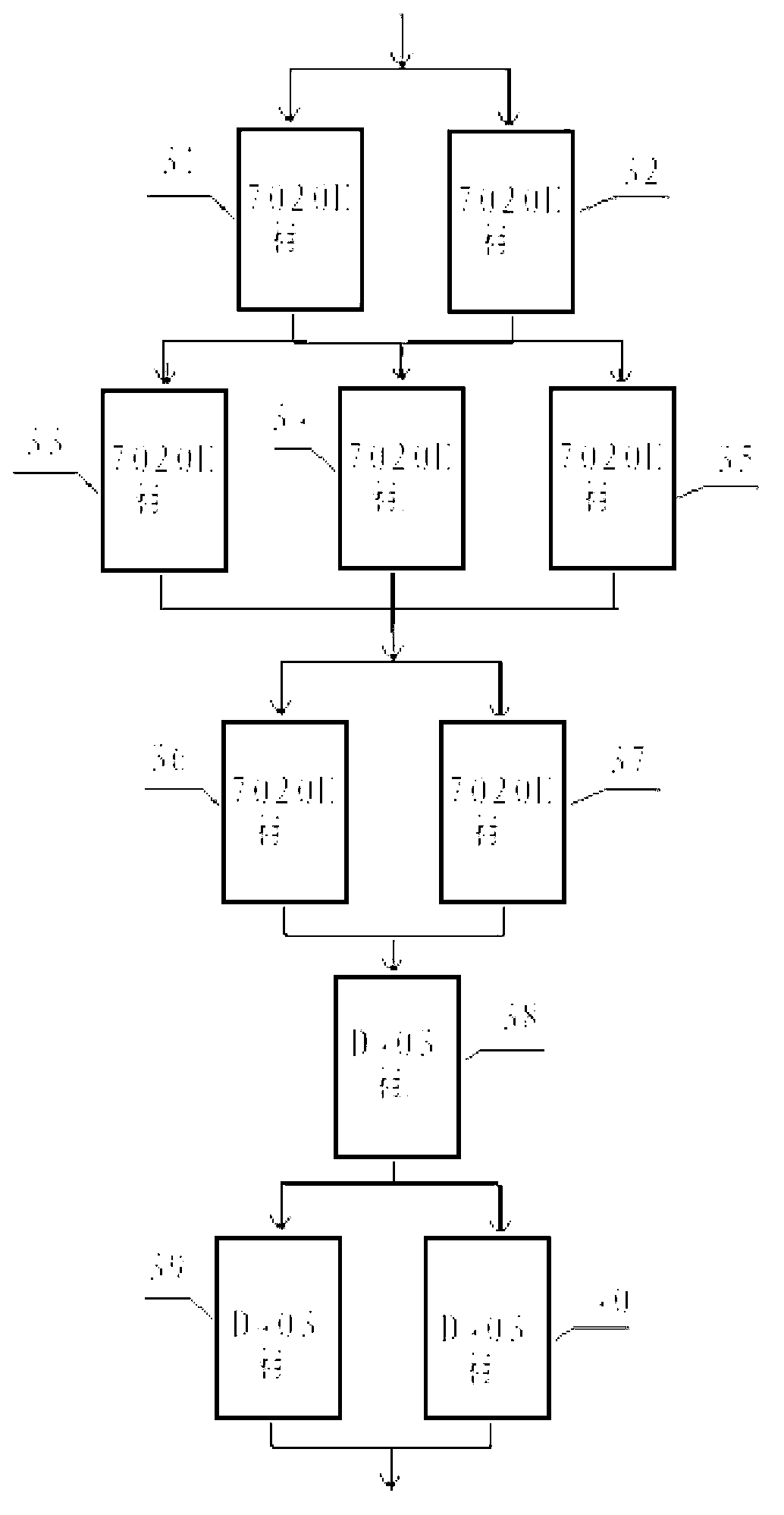

[0053] Contains 88 grams / liter of aluminum (calculated as alumina), 2.7 grams / liter of iron (calculated as iron oxide), 1.5 grams / liter of calcium (calculated as calcium oxide), and 1.2 grams / liter of magnesium (calculated as magnesium oxide) Calculate the aluminum chloride solution, adjust the pH value to 1.3 with hydrochloric acid solution, heat the temperature to 73°C, and press it into such as image 3 In the multi-stage resin column group shown, wherein resin columns 31, 32, 33, 34, 35, 36 and 37 are equipped with 7020H type cation exchange resin, and resin columns 38, 39 and 40 are equipped with D403 type chelating resin. The diameter-to-height ratio of resin columns 31, 32, 33, 34, 35, 36, 37, 39 and 40 is 0.6:1, and the resin loading capacity is 20ml respectively; the diameter-height ratio of resin column 38 is 1.8:1, and the resin loading capacity 40ml;. The aluminum chloride solution is processed by passing through the column method in parallel, and the incoming flo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com