Special nylon 6 composition for automobile engine hood and preparation method thereof

An automobile engine and composition technology, which is applied to the special nylon 6 composition for automobile engine cover and its preparation field, can solve the problems of affecting the appearance and painting performance of the product, difficult to ensure the sealing performance, and the product is prone to warping, etc., and achieves excellent performance. Effects of chemical properties and dimensional stability, high impact resistance, high ultra-high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

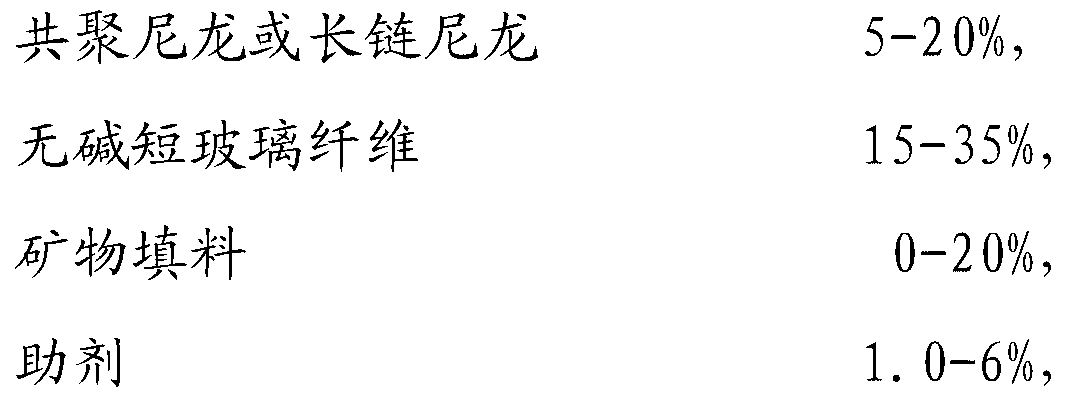

[0028] Embodiment 1: A special nylon 6 composition for an automobile engine cover, containing components and the mass percentages of each component are:

[0029] Nylon 6 60.9%,

[0030] Nylon copolymer 5%,

[0031] Alkali-free short glass fiber 30%,

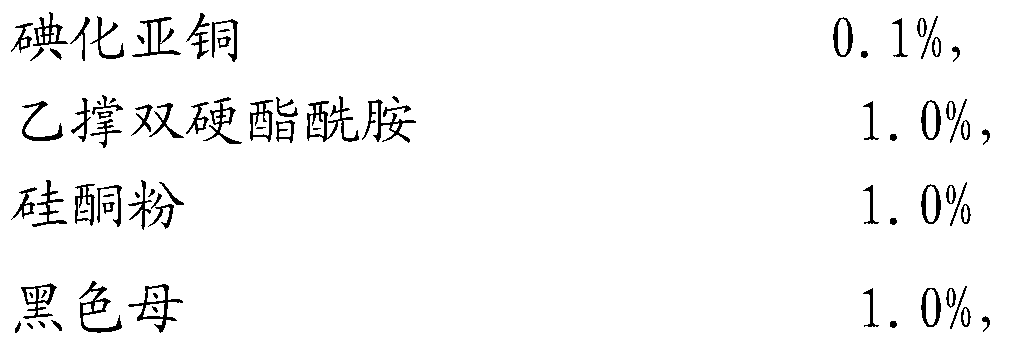

[0032] Auxiliary

[0033]

[0034] The copolymerized nylon is nylon 6 / 66 copolymer.

[0035] The auxiliary agent contains heat stabilizer, lubricant and dyeing agent.

[0036] The preparation method of above-mentioned special-purpose nylon 6 composition for automobile engine cover, comprises the steps:

[0037] 1) Weigh nylon 6, copolymerized nylon, alkali-free short glass fiber and additives according to the weight percentage of each component in the formula;

[0038] 2) Put nylon 6, copolymerized nylon and additives into a high-speed mixer and mix at high speed to obtain a blended material;

[0039] 3) Put the alkali-free short glass fiber and the blended material obtained in step 2) into the co-rotating twin-screw ext...

Embodiment 2

[0040] Embodiment 2: A special nylon 6 composition for an automobile engine cover, containing components and the mass percentages of each component are:

[0041] Nylon 6 49.9%,

[0042] Copolymer Nylon 10%,

[0043] Alkali-free short glass fiber 35%,

[0044] Auxiliary

[0045]

[0046] The copolymerized nylon is nylon 6 / 12 copolymer.

[0047] The auxiliary agent contains heat stabilizer, lubricant and dyeing agent.

[0048] The preparation method of above-mentioned special-purpose nylon 6 composition for automobile engine cover, comprises the steps:

[0049] 1) Weigh nylon 6, copolymerized nylon, alkali-free short glass fiber, mineral filler and additives according to the weight percentage of each component in the formula;

[0050] 2) Put nylon 6, copolymerized nylon and additives into a high-speed mixer and mix at high speed to obtain a blended material;

[0051] 3) Put the alkali-free short glass fiber and the blended material obtained in step 2) into the co-rotati...

Embodiment 3

[0052] Embodiment 3: A special nylon 6 composition for an automobile engine cover, containing components and the mass percentages of each component are:

[0053] Nylon 6 46.9%,

[0054] Copolymer Nylon 15%,

[0055] Alkali-free short glass fiber 35%,

[0056] Auxiliary

[0057]

[0058] The copolymerized nylon is nylon 6 / 10 copolymer.

[0059] The auxiliary agent contains heat stabilizer, lubricant and dyeing agent.

[0060] The preparation method of above-mentioned special-purpose nylon 6 composition for automobile engine cover, comprises the steps:

[0061] 1) Weigh nylon 6, copolymerized nylon, alkali-free short glass fiber and additives according to the weight percentage of each component in the formula;

[0062] 2) Put nylon 6, copolymerized nylon and additives into a high-speed mixer and mix at high speed to obtain a blended material;

[0063] 3) Put the alkali-free short glass fiber and the blended material obtained in step 2) into the co-rotating twin-screw extr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com