Continuous basalt fiber-reinforced halogen-free flame-retardant nylon material and preparation method thereof

A technology of basalt fiber and flame-retardant nylon, which is applied in the field of fiber-reinforced polymer materials and their preparation, continuous basalt fiber-reinforced halogen-free flame-retardant nylon materials and their preparation, can solve the problems of low toughness, achieve excellent mechanical properties, and prepare The effect of simple process and good flame retardant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

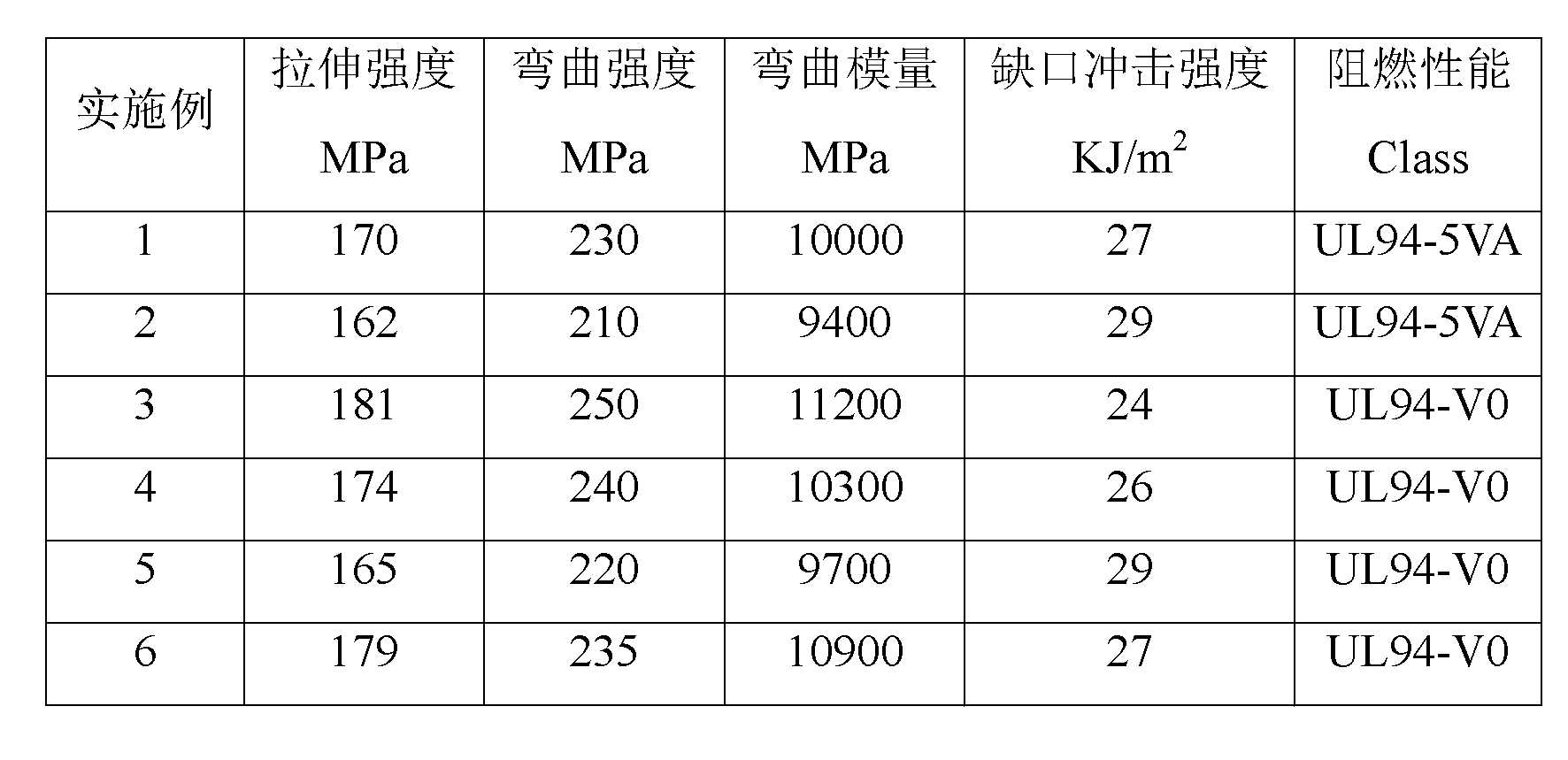

Examples

Embodiment 1

[0024] Preparation of continuous basalt fiber reinforced nylon masterbatch:

[0025] Mix 47% nylon resin PA6 M2400, 2% silane coupling agent (γ-aminopropyltriethoxysilane and γ-glycidyl etheroxypropyltrimethoxysilane in 1:1 mixture), 1% heat After the stabilizer (dilauryl thiodipropionate and 4-hydroxyoctadecanoanilide is mixed at a ratio of 1:1) is mixed evenly, the continuous basalt fiber is pulled through the impregnation die by using an impregnation die to prepare continuous basalt fibers Reinforced nylon masterbatch, in which the content of continuous basalt fiber is 50%;

[0026] Preparation of halogen-free flame retardant masterbatch:

[0027] Mix 15% polypropylene PP 320 powder (melt index 37g / 10min) with 69% halogen-free flame retardant (melamine phosphate and pentaerythritol phosphate ester compounded at 1:1), 15% flame retardant synergist (zinc borate and Titanium dioxide compounded at 1:1), 1% heat stabilizer (4-hydroxyoctadecanoanilide and triphenyl phosphite mi...

Embodiment 2

[0031] Preparation of continuous basalt fiber reinforced nylon masterbatch:

[0032] With embodiment 1;

[0033] Preparation of halogen-free flame retardant masterbatch:

[0034] 30% bimodal polyethylene FB2230 and 60% halogen-free flame retardant (melamine phosphate and red phosphorus compounded at 2:1), 9% flame retardant synergist (zinc borate and hydrotalcite compounded at 3:1 ), 1% heat stabilizer (4-hydroxyoctadecanoanilide and triphenyl phosphite mixed at 1:1) are mixed evenly, and melted and granulated in an internal mixer to obtain the required halogen-free flame-retardant master grain.

[0035] Preparation of continuous basalt fiber reinforced halogen-free flame-retardant nylon material:

[0036] Mix the continuous basalt fiber reinforced nylon masterbatch with the halogen-free flame-retardant masterbatch at a ratio of 2:1 to prepare the required continuous basalt fiber-reinforced halogen-free flame-retardant nylon material. In the final composite material, the c...

Embodiment 3

[0038] Preparation of continuous basalt fiber reinforced nylon masterbatch:

[0039] Mix 58% nylon resin PA66 HY26, 1% silane coupling agent (γ-methacryloxypropyltrimethoxysilane and γ-glycidyl etheroxypropyltrimethoxysilane in 1:1 mix) , 1% heat stabilizer (dilauryl thiodipropionate and 4-hydroxyoctadecanoanilide mixed at 1:1), using an impregnation die, pulling the continuous basalt fiber through the impregnation die to prepare the Continuous basalt fiber reinforced nylon masterbatch, wherein the content of continuous basalt fiber is 40%;

[0040] Preparation of halogen-free flame retardant masterbatch:

[0041] With embodiment 1;

[0042] Preparation of continuous basalt fiber reinforced halogen-free flame-retardant nylon material:

[0043]Mix the continuous basalt fiber-reinforced nylon masterbatch with the halogen-free flame retardant masterbatch at a ratio of 5:2 to prepare the required continuous basalt fiber-reinforced halogen-free flame-retardant nylon material. I...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com