A kind of tantalum-containing titanium-aluminum base alloy ingot and preparation method thereof

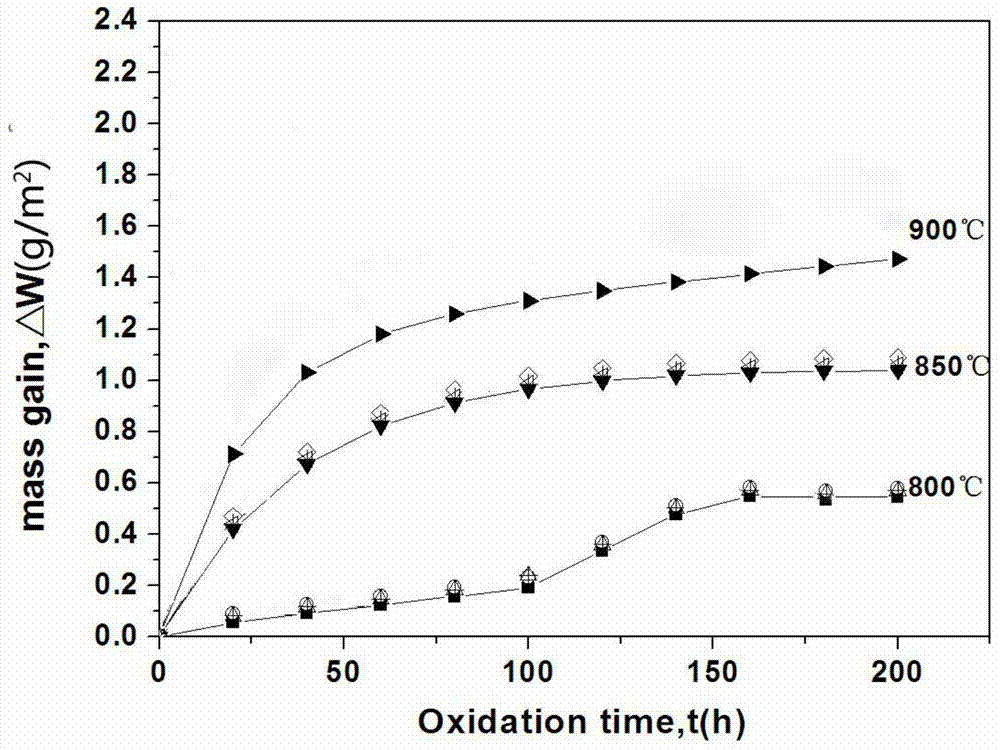

A technology based on alloys and titanium-aluminum, applied in the field of titanium-aluminum-based alloy ingots containing tantalum and its preparation, can solve the problems of low melting point, uncontrollable melting current, difficulty in obtaining homogeneous ingots, etc., and achieve wide source of raw materials, Excellent anti-oxidation performance, the effect of ensuring homogeneity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039]The titanium-aluminum-based alloy ingot containing tantalum in this example is composed of the following components in atomic percentage: Al46.5%, Ta3%, Cr2.0%, W0.2%, and the balance is Ti and inevitable impurities.

[0040] The preparation method of this embodiment comprises the following steps:

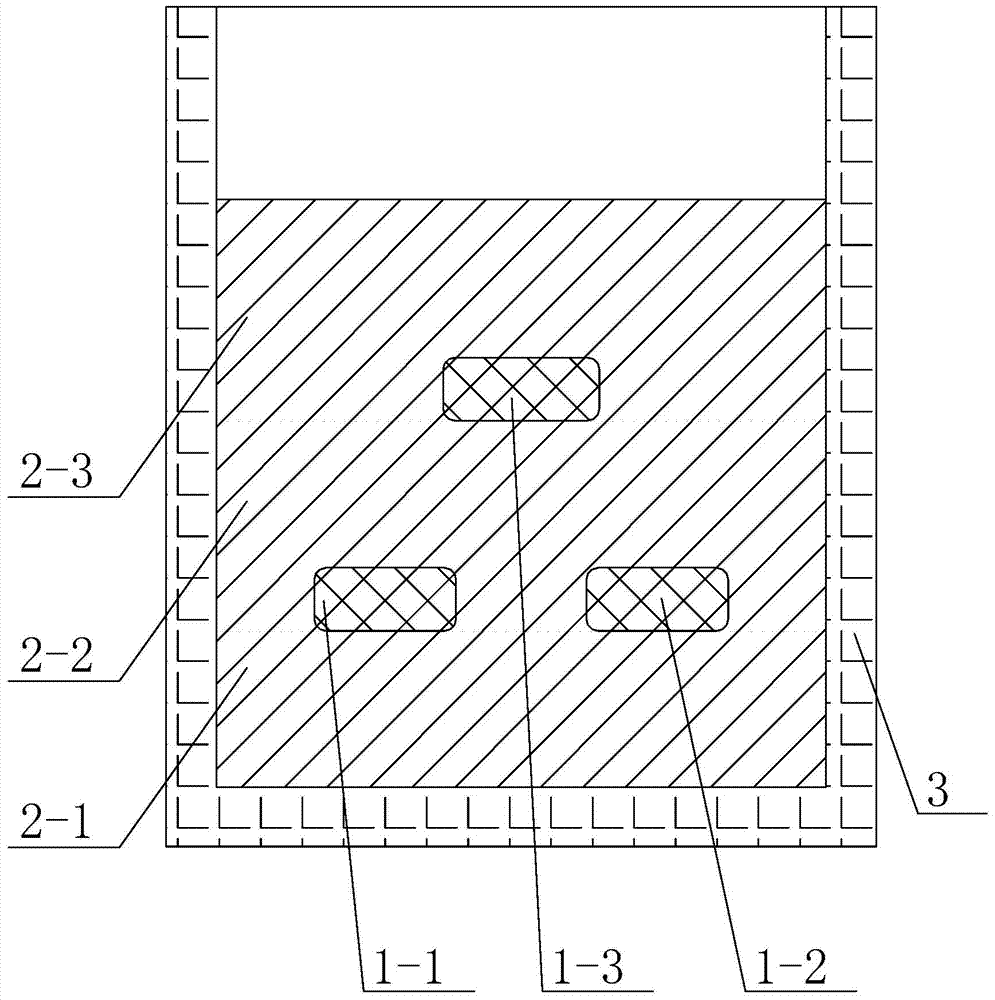

[0041] Step 1: Weigh the following raw materials according to the atomic percentage of each component in the titanium-aluminum-based alloy ingot containing tantalum: tantalum powder, metal chromium particles, Al-W master alloy particles, aluminum foil, aluminum beans, titanium powder and sponge Titanium particles; in this example, the particle size of the tantalum powder is -325 mesh, the particle size of the titanium powder is -200 mesh, the particle size of the titanium sponge particles is not more than 3mm, and the particle size of the aluminum beans is not more than 10mm. , the particle sizes of the metal chromium particles and the Al-W master alloy particles are not grea...

Embodiment 2

[0050] The titanium-aluminum-based alloy ingot containing tantalum in this example is composed of the following components in atomic percentage: Al46.5%, Ta2.5%, Cr2.0%, W0.2%, and the balance is Ti and inevitable impurities.

[0051] The preparation method of the titanium-aluminum-based alloy ingot containing tantalum in this example is the same as that in Example 1.

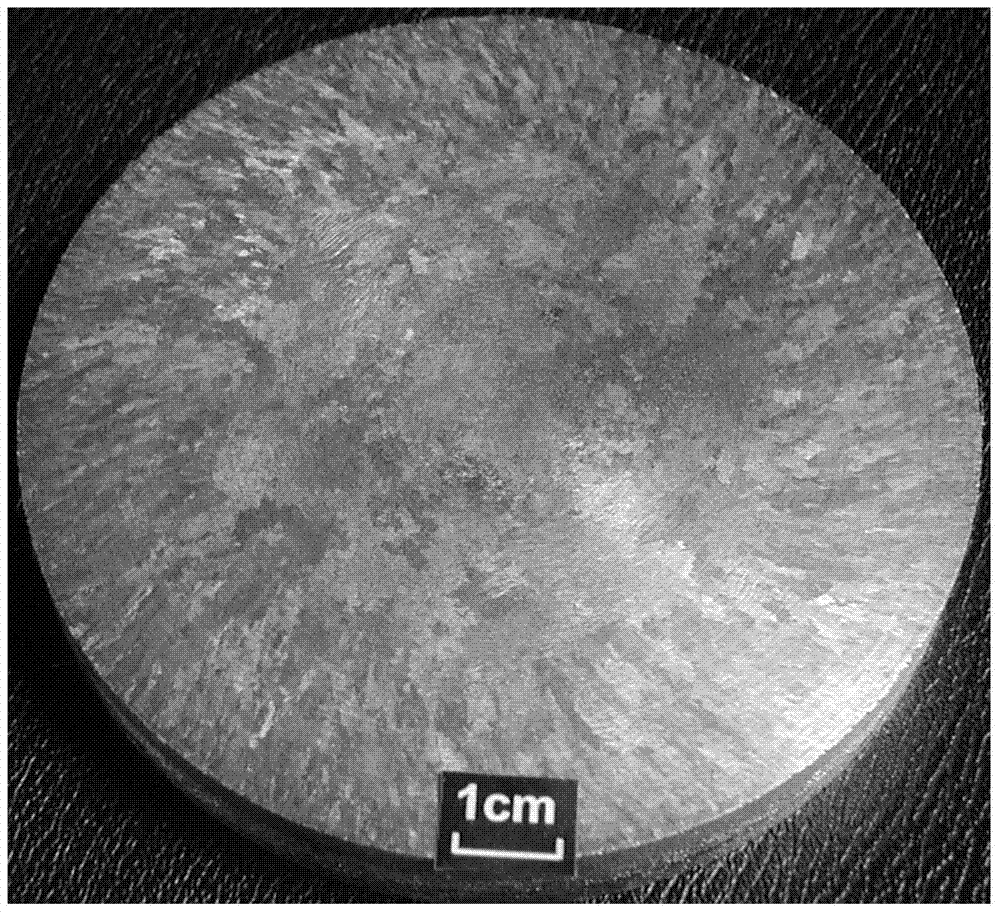

[0052] The structure of the titanium-aluminum-based alloy ingot containing tantalum in this example is uniform, and there are no pores, inclusions, and no frit.

Embodiment 3

[0054] The titanium-aluminum-based alloy ingot containing tantalum in this embodiment is composed of the following atomic percentages: Al46.5%, Ta2%, Cr2.0%, W0.2%, and the balance is Ti and inevitable impurities.

[0055] The preparation method of the titanium-aluminum-based alloy ingot containing tantalum in this example is the same as that in Example 1

[0056] The structure of the titanium-aluminum-based alloy ingot containing tantalum in this example is uniform, and there are no pores, inclusions, and no frit.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com