High-speed generator directly driven by air turbine

A technology of high-speed generators and air turbines, which is applied in the direction of engine components, machines/engines, electromechanical devices, etc., can solve the problems of increased flight time of aircraft, inability to be equipped with generators, and infeasibility, and achieve compact structure and reduced Radial size, effect of increasing the upper limit of rotation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

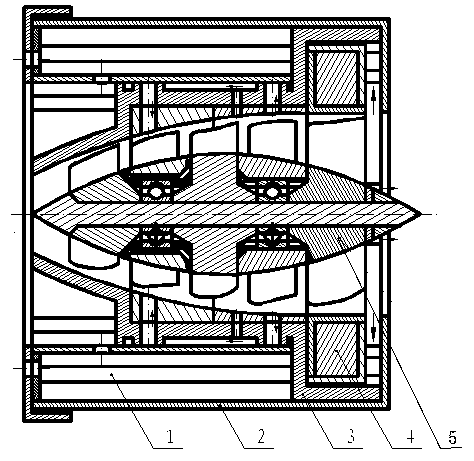

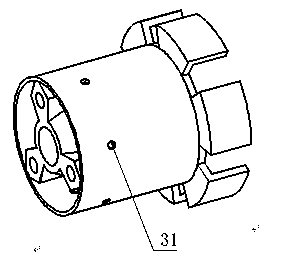

[0021] Attached below Figure 1-2 The present invention is further described in detail: a high-speed generator directly driven by an air turbine includes a generator casing 2, a casing 3, a turbine rotor 5, and also includes a permanent magnet assembly 4, a coil winding 1, and the turbine rotor 5 and The casing 3 forms an annular airflow passage, the permanent magnet assembly 4 forms a ring shape and is fixed on the outer edge of the last stage turbine rotor of the turbine rotor 5, and the coil winding 1 surrounds the casing 3 in a cylindrical shape On the outer surface, the generator casing 2 fixes the coil winding 1 to the casing 3 and plays a role of structural protection for the coil winding. The heat shield of the casing isolates the heat radiation on the load-bearing casing of the casing and the hot air surrounding the load-bearing casing of the casing from the coil windings, thereby blocking the transfer of heat to the coil windings.

[0022] This embodiment adopts 3-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com