Ultrasound and oxygen-enriched combustion device and working method thereof

An oxygen-enriched combustion-supporting, ultrasonic technology, applied in the direction of charging systems, combustion engines, internal combustion piston engines, etc., can solve single problems, achieve the effects of reducing PM2.5, reducing HC, and increasing output power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further explained below in conjunction with specific drawings.

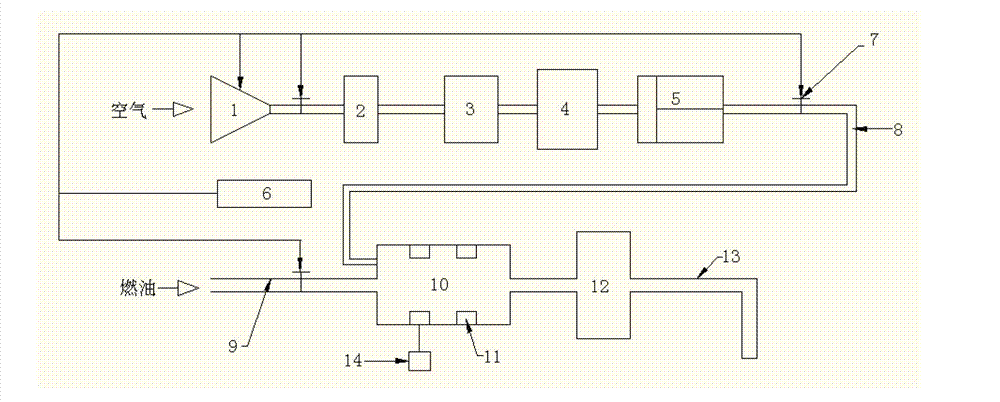

[0022] Reference figure 1 , Ultrasonic, oxygen-enriched combustion-supporting device, including PLC smart air pump (1), dust collector (2), dryer (3), pressure swing adsorption oxygen generator (4), vacuum pump (5), PLC (6), PLC Intelligent control flow valve (7), oxygen-enriched air pipeline (8), oil pipeline (9), ultrasonic treatment chamber (10), ultrasonic transducer (11), internal combustion engine (12), exhaust system (13) , Ultrasonic generator (14).

[0023] A PLC intelligent control flow valve (7) is provided between the PLC intelligent air pump (1) and the dust collector (2), which is used to adjust the amount of air entering the PSA oxygen generator (4). A PLC intelligent control flow valve (7) is installed on the oxygen-enriched air gas pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com