Three-dimensional thermoelectricity energy collector and manufacturing method thereof

The technology of an energy harvester and manufacturing method is applied in the field of three-dimensional thermoelectric energy harvester and its manufacturing, which can solve the problems of low energy collection efficiency, low manufacturing efficiency, and high manufacturing cost, and achieve improved mechanical stability, high Seebeck coefficient, The effect of simplifying the manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

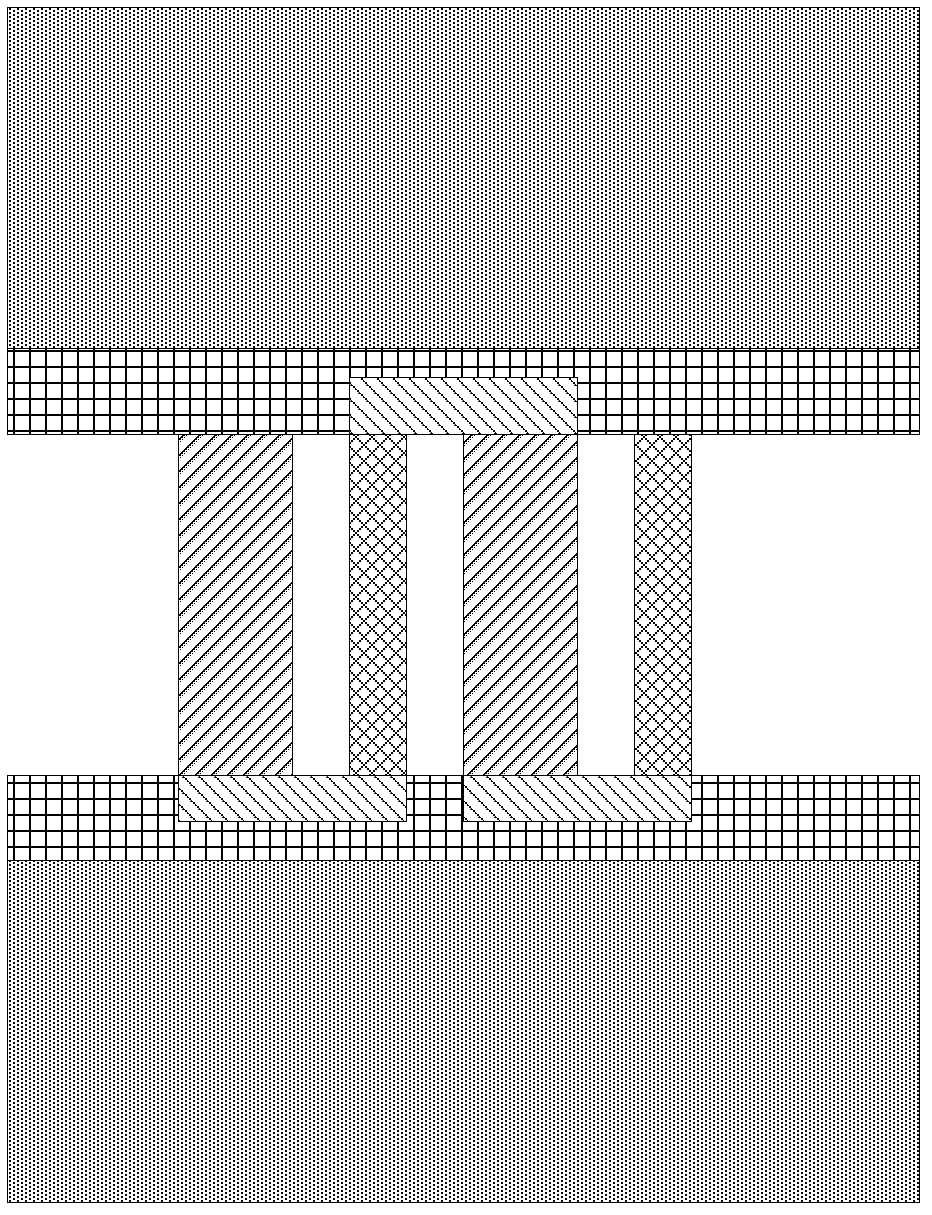

[0057] Such as figure 2 a~ Figure 11 As shown, the present invention provides a method for manufacturing a three-dimensional thermoelectric energy harvester, at least including the following steps:

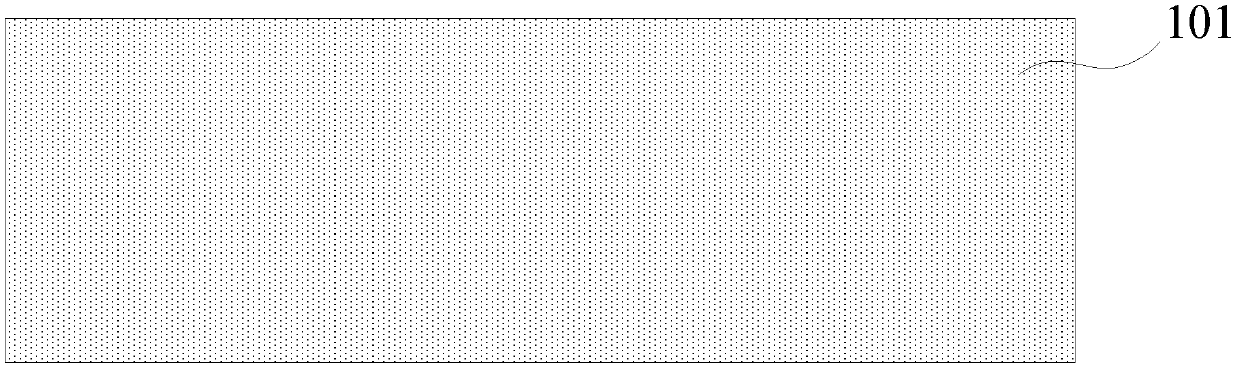

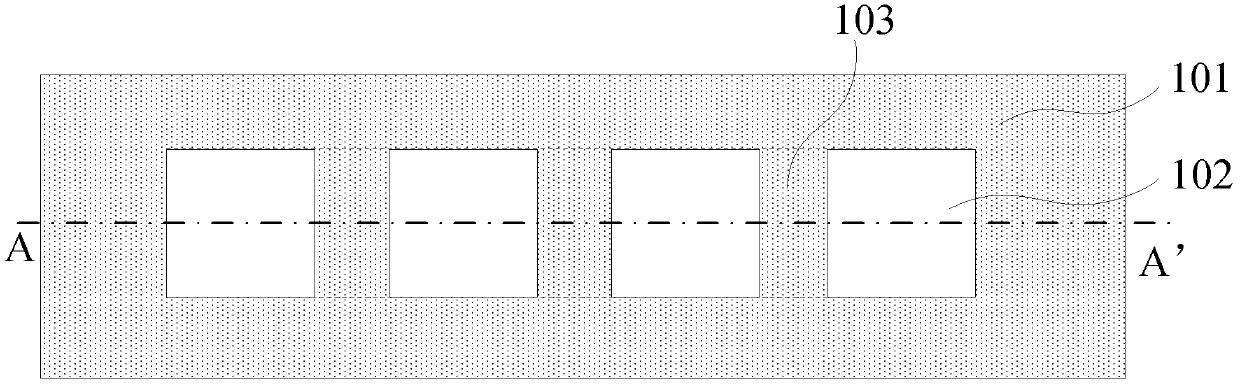

[0058] Such as Figure 2 ~ Figure 3b As shown, step 1) is carried out at first, providing a silicon substrate 101, etching the upper surface of the silicon substrate 101 to form a plurality of grooves 102 arranged at intervals, by each of the grooves 102 and the grooves 102 The area where silicon pillars 103 are to be prepared constitutes a thermopile area. In this embodiment, the silicon substrate 101 is selected as a low-resistance silicon substrate 101. Since the low-resistance silicon substrate has a higher bottom Seebeck coefficient and a lower resistance value, it can ensure a higher temperature when it is made into a thermoelectric column. High thermoelectric efficiency. In order to ensure a more accurate process, in this step, the low-resistance silicon substrate 101...

Embodiment 2

[0067] see Figure 2 ~ Figure 10b and Figure 12 , as shown in the figure, the basic steps of the manufacturing method of the three-dimensional thermoelectric energy harvester of this embodiment are as in Embodiment 1, wherein, in order to further increase the mechanical stability and thermoelectric efficiency of the thermopile, in the step 7), increase the A step of filling the annular groove 108 with an insulating material 109 .

Embodiment 3

[0069] see Figure 2 ~ Figure 10b and Figure 13 ~ Figure 14 , as shown in the figure, the basic steps of the manufacturing method of the three-dimensional thermoelectric energy harvester of this embodiment are as in embodiment 1 or embodiment 2, wherein, in order to realize the monolithic integration of the three-dimensional thermoelectric energy harvester and the circuit of the present invention, directly To supply power to the circuit in the chip, in the manufacturing method of the three-dimensional thermoelectric energy harvester of the present invention, it also includes the step of manufacturing CMOS circuit structures 113 and 114 on the upper supporting substrate 111 and the lower supporting substrate 112, and The upper and lower protection layers 121 and 122 are etched to form the wiring hole 115, and then metal wiring is formed in the wiring hole 115 to connect the CMOS circuit and the upper and lower metal wiring. Then the upper and lower protection layers 121 and 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com