Built-in outer rotor permanent-magnet motor direct-drive mine hoist

A mine hoist and permanent magnet motor technology, applied in the field of mining machinery, can solve problems such as threats to system safety operation, difficulty in ensuring air gap uniformity, and increased complexity of the control system, so as to achieve positioning and support operation, and avoid static instability Problems, excellent effect of control characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

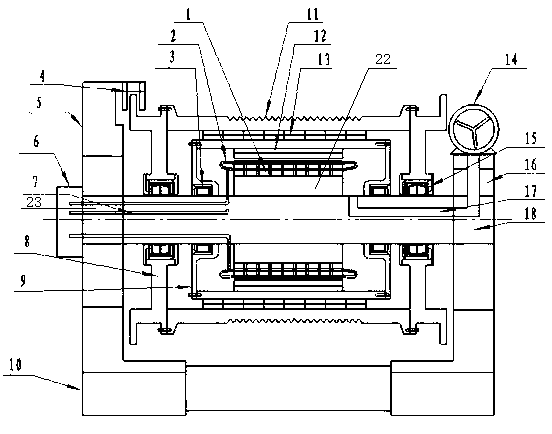

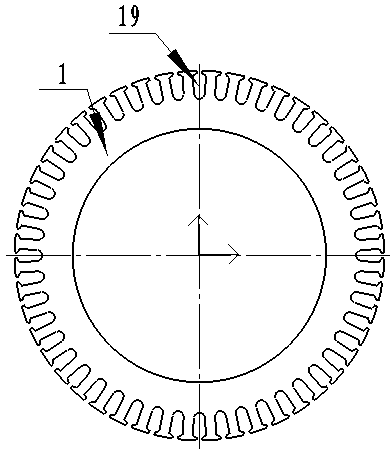

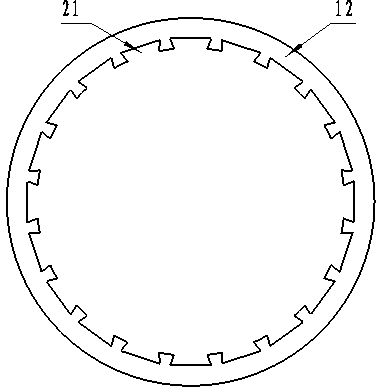

[0043] The structure of a built-in outer rotor permanent magnet motor direct drive mine hoist of the present invention is as follows: figure 1 As shown, the stator 1 of the permanent magnet motor is set on the hoist main shaft 18 through the stator supporting structure 22, and the interior of the hoist main shaft 18 is provided with an axial through hole 23, and the winding lead wire 7 of the permanent magnet motor winding 2 is drawn out through the axial through hole 23 And connect the terminal box 6 of the permanent magnet motor. The rotor support structure 9 and the inner cylindrical roller bearing 3 are installed on the main shaft 18 of the hoist along both sides of the permanent magnet motor stator 1, the outer rotor 12 of the permanent magnet motor is installed on the upper part of the rotor support structure 9, and the two sides of the hoist main shaft 18 are equipped with outer alignment Bearing 15 and reel support structure 8, wire rope reel 11 is installed on the upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com