Method for combined treatment of wastewater of phenol-containing gas by ozone flocculant

A combined treatment and oxidation treatment technology, applied in chemical instruments and methods, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc. High level of pollutants and phenolic substances, to achieve the effect of good effluent quality, improved biodegradability, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

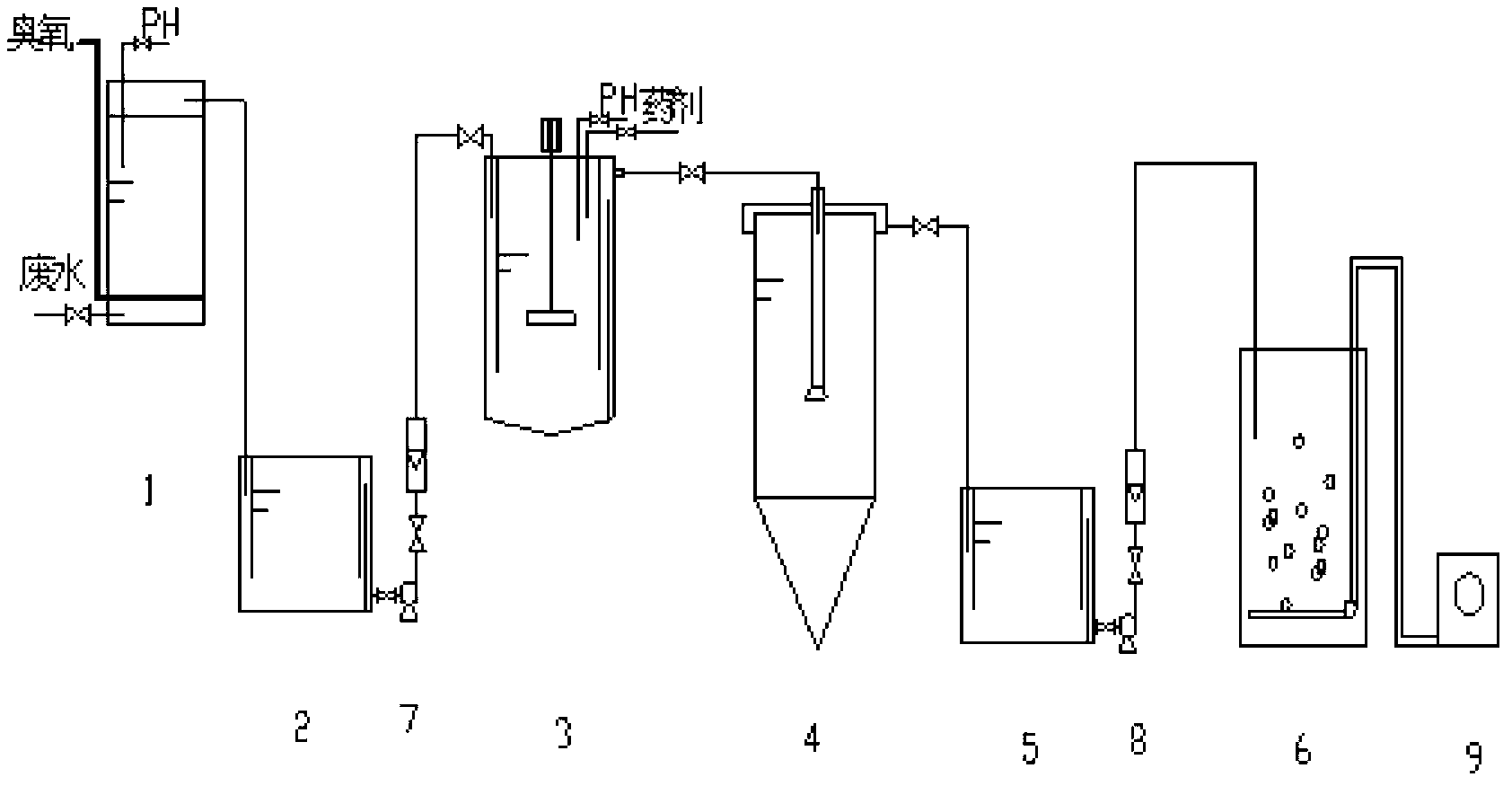

Image

Examples

Embodiment 1

[0033] A certain biochemical SNG wastewater is advanced treated by the ozone-dosing flocculation-biology combined process of the present invention. The COD of SNG wastewater after biochemical treatment is 220 mg / L, B / C 0.10, and phenol 73 mg / L. Firstly, ozone is introduced to carry out ozone oxidation treatment. The ratio of the dosage of ozone to the COD of SNG wastewater is 0.1:1, the oxidation treatment time is 10 minutes, and the pH is 8.0. After oxidation, the effluent flows into the primary storage tank and stays for 20 minutes. At this time, the COD of the wastewater is 200 mg / L, B / C 0.32, and phenol is 35 mg / L; the effluent from the primary storage tank is subjected to chemical dosing and flocculation reaction, and the aluminum-containing compound chemical is added, and the mass ratio of the chemical dose to the wastewater is 0.005: 1. Control the pH to 8.5. At this time, the COD of the wastewater is 150mg / L; the flocculation effluent flows into the sedimentation tank,...

Embodiment 2

[0036]A certain biochemical SNG wastewater is advanced treated by the ozone-dosing flocculation-biology combined process of the present invention. The COD of SNG wastewater after biochemical treatment is 240 mg / L, B / C 0.12, and phenol 84 mg / L. Firstly, ozone is introduced to carry out ozone oxidation treatment. The ratio of the dosage of ozone to the COD of SNG wastewater is 0.15:1, the oxidation treatment time is 12 minutes, and the pH is 8.5. After oxidation, the effluent flows into the primary storage tank and stays for 25 minutes. At this time, the COD of the wastewater is 208mg / L, the B / C is 0.35, and the phenol is 35mg / L; the effluent from the primary storage tank is subjected to chemical dosing and flocculation reaction, and the aluminum-containing composite chemical is added, and the mass ratio of the chemical dose to the wastewater is 0.01:1 , control the pH to 8.5, at this time, the COD of the wastewater is 160 mg / L; the flocculation effluent flows into the sedimenta...

Embodiment 3

[0038] A certain biochemical SNG wastewater is advanced treated by the ozone-dosing flocculation-biology combined process of the present invention. The COD of SNG wastewater after biochemical treatment is 282 mg / L, B / C 0.15, and phenol 64 mg / L. Firstly, ozone is introduced to carry out ozone oxidation treatment. The ratio of the dosage of ozone to the COD of SNG wastewater is 0.2:1, the oxidation treatment time is 12 minutes, and the pH is 8.0. After oxidation, the effluent flows into the primary storage tank and stays for 30 minutes. At this time, the COD of the wastewater is 218 mg / L, the B / C is 0.37, and the phenol is 28 mg / L; the effluent from the primary storage tank is subjected to the dosing and flocculation reaction, and the aluminum-containing compound reagent is added, and the mass ratio of the dose to the wastewater is 0.02 : 1, control pH 8.6, at this moment, the COD of waste water is 148mg / L; The flocculation effluent flows into the sedimentation tank, after stayi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com