O, O-dialkylphosphoryl thiochloride preparation method without waste residue

A technology of alkyl thiophosphoryl and ethyl thiophosphoryl, which is applied in the field of O,O-dialkyl thiophosphoryl chloride free-slag preparation, can solve the problem that it is difficult to deal with sticky sulfur waste residues, the reaction heat is large, and the treatment It is difficult to solve problems such as high difficulty, and achieves the effects of easy industrialization, high yield and low production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

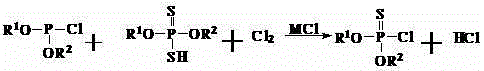

Method used

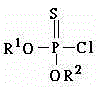

Image

Examples

Embodiment 1

[0025] In a 1000ml four-neck flask with an air duct, a cooling device, and a thermometer, 310g of diethyl chlorophosphite, 372g of O, O-diethyl phosphorodithioate, and 2g of aluminum chloride were successively put in; Slowly raise the temperature to 35°C, feed 164g of chlorine gas within 4 hours, keep it warm for 4 hours, use nitrogen to drive away the excess chlorine and hydrogen chloride gas; stir intermittently, quickly cool down to 25°C; filter at 25°C to obtain O,O- Diethyl thiophosphoryl chloride 735g, the content is 98%; Calculated with diethyl chlorophosphite, the yield is 96%.

Embodiment 2

[0027] In a 1000ml four-neck flask with an air duct, a cooling device, and a thermometer, 310g of diethyl chlorophosphite, 372g of O, O-diethyl phosphorodithioate, and 2g of aluminum chloride were successively put in; Slowly raise the temperature to 35°C, feed 164g of chlorine gas within 4 hours, keep it warm for 4 hours, use nitrogen to drive away the excess chlorine and hydrogen chloride gas; cool down to 25°C; filter at 25°C, wash the filtrate with water, and separate to obtain O,O -Diethylphosphorylthiochloride 715g, content is 99.5%; Calculated yield is 95% with diethyl chlorophosphite.

Embodiment 3

[0029] Into a 1000ml four-neck flask with air duct, cooling device and thermometer, put 310g of diethyl chlorophosphite, 372g of O,O-diethyl phosphorodithioate and 0.5g of aluminum chloride in sequence. and the last batch of filter residue 2.5g; slowly warm up to 35°C, feed 164g of chlorine gas within 4 hours, keep warm for 4 hours, use nitrogen to drive away the excess chlorine and hydrogen chloride gas; intermittently stir, quickly cool down to 25°C; at 25°C O, O-diethylphosphorothiochloride 735g was obtained by filtration at a lower temperature, with a content of 98%; the yield was 96% based on diethyl chlorophosphite.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com