Compound type hydrate inhibitor

An inhibitor and composite technology, applied in drilling compositions, piping systems, chemical instruments and methods, etc., can solve the problems of low inhibitory activity, damage to the internal components of the wellbore, increase the pressure difference of the pipeline, etc. Time, wide range of applications, effect of improving suppression effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

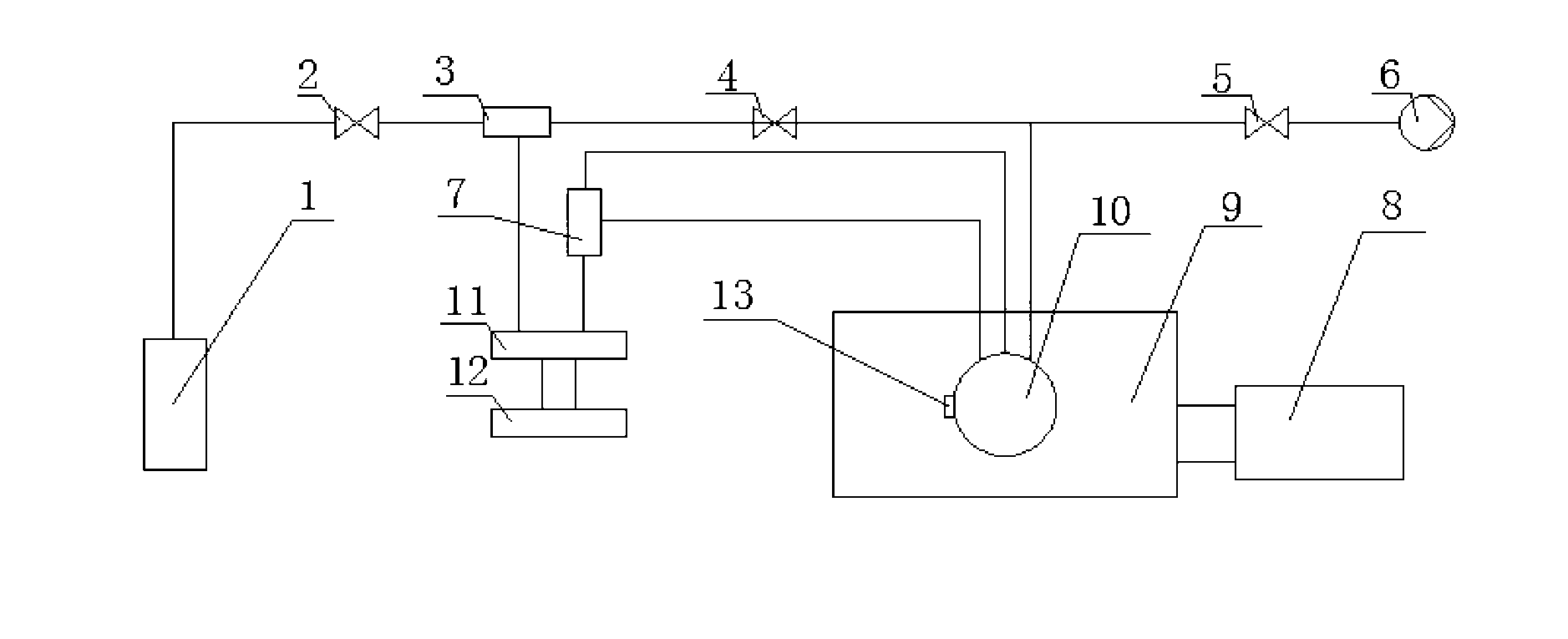

Method used

Image

Examples

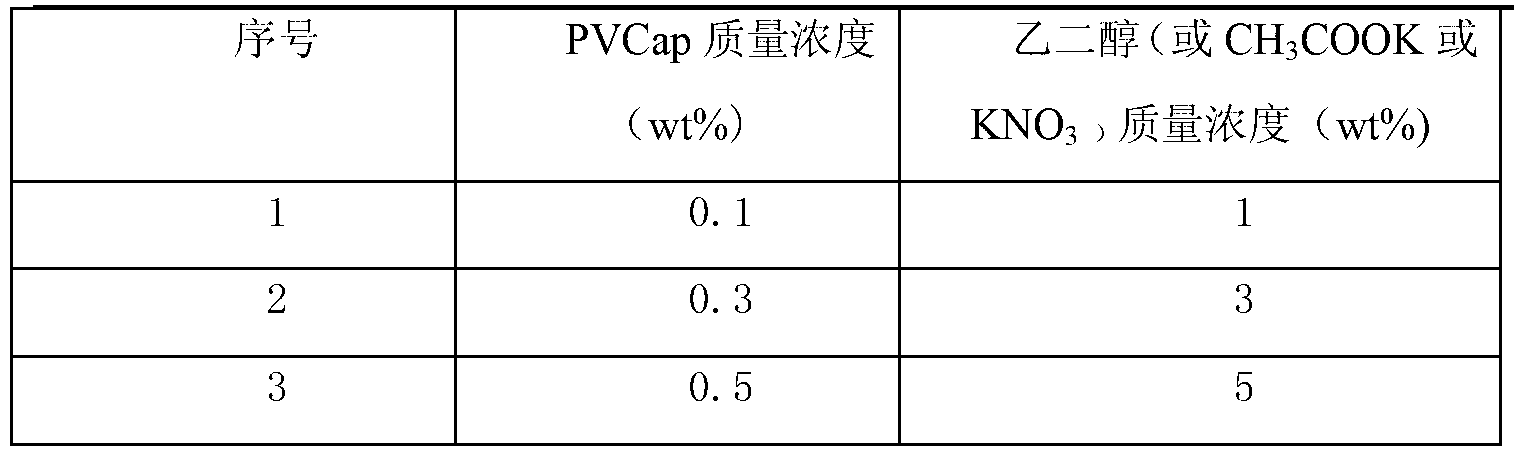

Embodiment 1

[0041] 0.1% PVCap and 1% ethylene glycol compound, the experimental procedure is the same as above, the results show that the induction time is 65min, the reaction completion time is 180min, the pressure drop of methane gas is 0.6MPa, and its inhibition performance is more obvious than that of pure water.

Embodiment 2

[0043] 0.1% PVCap and 3% ethylene glycol compounded, the experimental procedure is the same as above, the results show that the induction time is 78min, the reaction completion time is 200min, the pressure drop of methane gas is 0.5MPa, and its inhibition performance is significantly improved.

Embodiment 3

[0045] 0.1% PVCap and 5% ethylene glycol were compounded, the experimental procedure was the same as above, the results showed that the induction time was 85min, the reaction completion time was 215min, the pressure drop of methane gas was 0.45MPa, and the inhibition performance was significantly improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com