Diesel engine exhaust aftertreatment device temperature riser control system and control method

A diesel engine and exhaust post-treatment technology, which is applied to the electronic control of exhaust treatment devices, exhaust treatment, exhaust devices, etc., can solve the problems of inability to achieve low-temperature ignition, inability to ignite diesel, poor ignition reliability, etc., to achieve Avoid the effects of excessive heating, complete regeneration, and sufficient combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

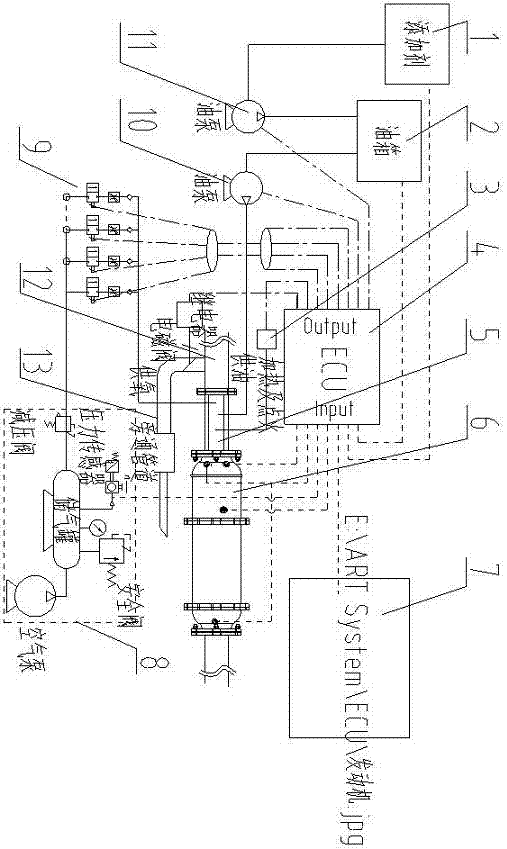

[0010] Embodiment 1: with reference to attached figure 1 . A diesel engine exhaust post-processing device warmer control system, the driving computer 4 signal input terminals are respectively connected to the diesel engine 7 speed signal output terminal, the diesel engine exhaust post-processing device 6-fold pressure signal output terminal, and the post-processing device warmer 5 The temperature signal output end, the signal output end of the air storage tank pressure sensor in the air compression device 8, the output end of the oil level signal of the fuel tank 2 and the output end of the additive tank 1 addition signal are connected, and the signal output end of the trip computer 4 is respectively It is connected with the switch signal control terminal of the mixing oil pump 11, the switch signal control terminal of the oil supply pump 10, the switch signal control terminal of the multi-way air valve 9 and the switch signal control terminal of the temperature rise controlle...

Embodiment 2

[0011] Embodiment 2: On the basis of Embodiment 1, the exhaust pipe 12 of the diesel engine is connected with a bypass pipe 13 through a solenoid valve, and the switch signal control end of the solenoid valve is connected with the signal output end of the trip computer 4 .

Embodiment 3

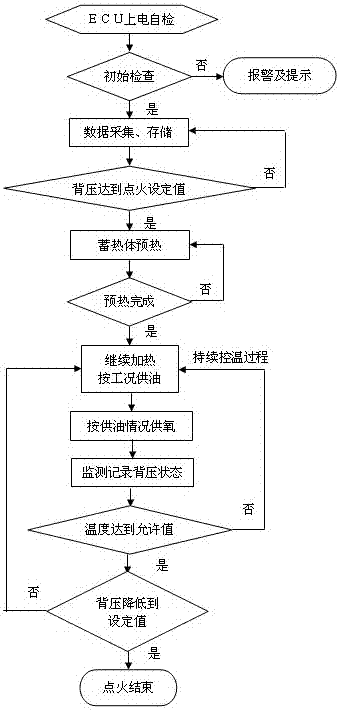

[0012] Embodiment 3: with reference to attached figure 2 . On the basis of Embodiment 1, a method for controlling the temperature riser of a diesel engine exhaust post-processing device, the trip computer 4 powers on and self-inspects, and the initial inspection refers to that the ECU performs data collection on the peripheral equipment, and autonomously controls or prompts that the fuel tank is refueled. It is necessary to add a corresponding amount of additives, and perform data collection, display or alarm, detect the capacity of the ECU memory, and prompt the status of data collection and storage. The ECU memory should be able to store more than 15 days of collected data, and it will be automatically cleared when the storage is full. When the 6 times pressure of the diesel engine exhaust post-processing device reaches the set value of the double pressure regeneration, the driving computer 4 instructs the temperature rise controller 3 to turn on the power supply to the el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com