Method for preparing high-performance sintered Nd-Fe-B magnet

A neodymium iron boron and magnet technology, used in magnetic objects, inductance/transformer/magnet manufacturing, magnetic materials, etc., can solve the problems that vacuum and pressure cannot be achieved, pressure cannot be applied, and vacuum cannot be evacuated, and the sintering temperature cannot be reduced. , The effect of increasing magnet density and uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

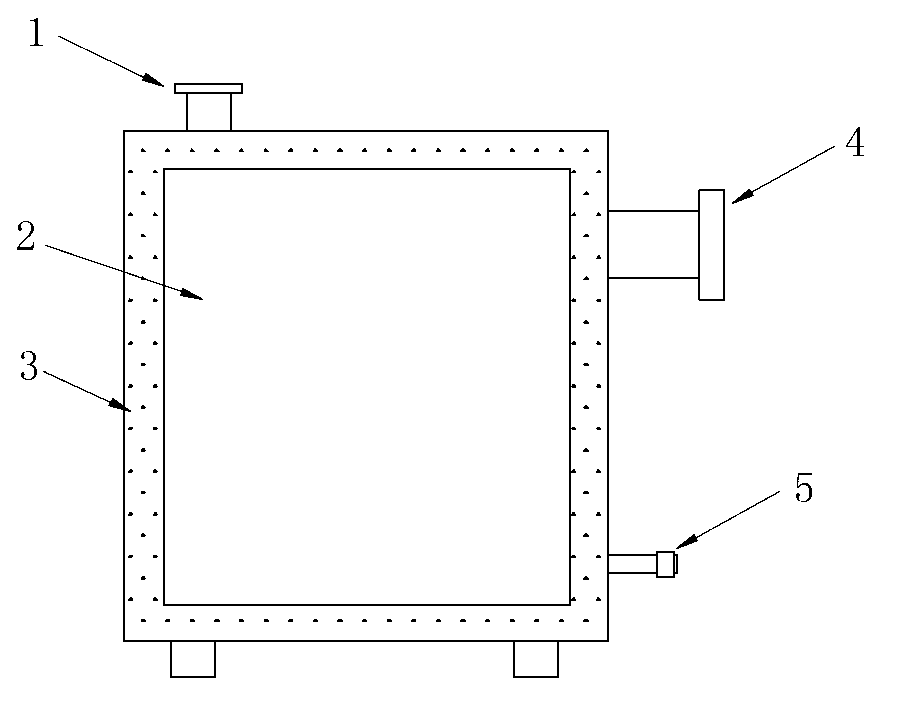

Image

Examples

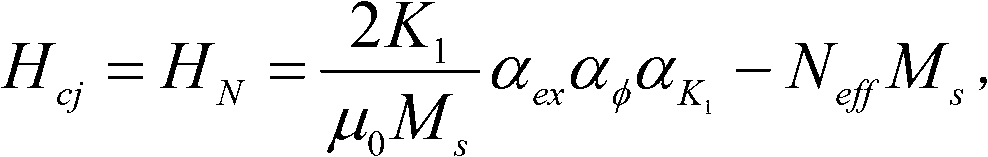

Embodiment 1

[0018] The selected magnet composition is Nd 13.5 Dy 0.5 Fe 79.97 B 6.03 , the alloy is smelted in a vacuum melting furnace with a vacuum degree of 10 -3 Pa, the alloy is cast using the quick-setting casting technology, and the thickness of the SC sheet is about 0.25~0.35mm. It is made into powder by hydrogen breaking and jet milling. After the powder is loosely packed, magnetic field orientation and pressing are carried out. The loose packing density is about 1.5g / cm 3 , the orientation field is greater than 1.5T. Next is the sintering stage, which can be sintered in two ways: one is the current sintering method, first vacuumize, and then continue to vacuumize, exhaust and heat up. Argon air cooling, magnet number set to 1 #The other is the sintering method of the present invention, first vacuumize, then continue to vacuumize and exhaust and heat up stage, after the exhaust finishes, stop vacuumizing before reaching or reaching the sintering temperature soon, pass into...

Embodiment 2

[0022] The selected magnet composition is Nd 13.5 Dy 0.5 Fe 79.97 B 6.03 , the alloy is smelted in a vacuum melting furnace with a vacuum degree of 10 -3 Pa, the alloy is cast using the quick-setting casting technology, and the thickness of the SC sheet is about 0.25~0.35mm. It is made into powder by hydrogen breaking and jet milling. After the powder is loosely packed, magnetic field orientation and pressing are carried out. The loose packing density is about 1.5g / cm 3 , the orientation field is greater than 1.5T. Next is the sintering stage, which is divided into two ways: one is to vacuumize first, and then continue to vacuumize, exhaust and heat up. Pure Ar gas is pressurized, the pressure is 10Mpa, sintering is carried out at a sintering temperature of 1080°C, and the temperature is kept for 3 hours. The next step is to continue vacuuming, exhausting and heating up. After the degassing is over, the vacuuming is stopped before reaching the sintering temperature, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com