Semiconductor power module package structure and preparation method thereof

A power module and packaging structure technology, which is applied in semiconductor/solid-state device manufacturing, semiconductor devices, semiconductor/solid-state device components, etc., can solve the problems of inflexible combination, insecurity, and electrification of supporting platforms, and achieve physical volume reduction, The effect of improving the service life and expanding the application field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

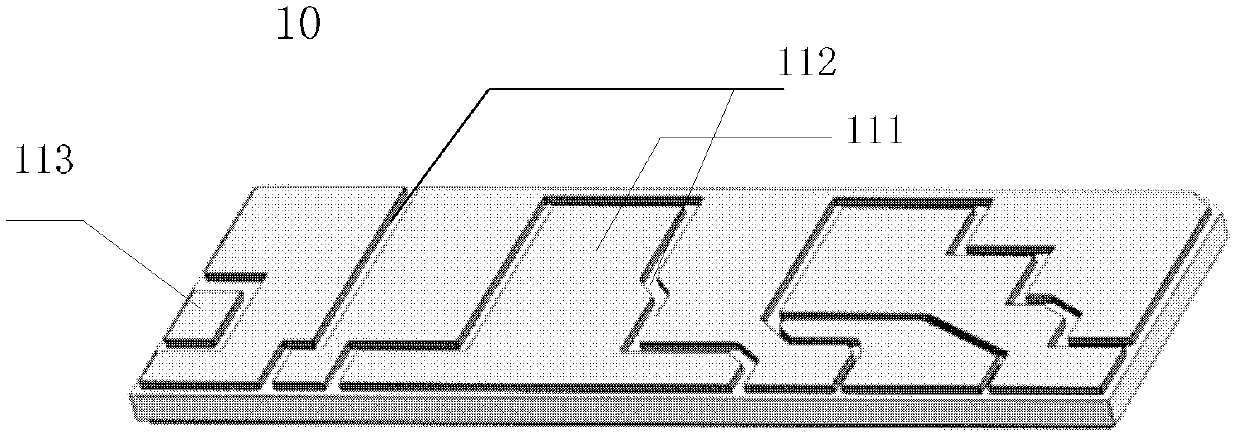

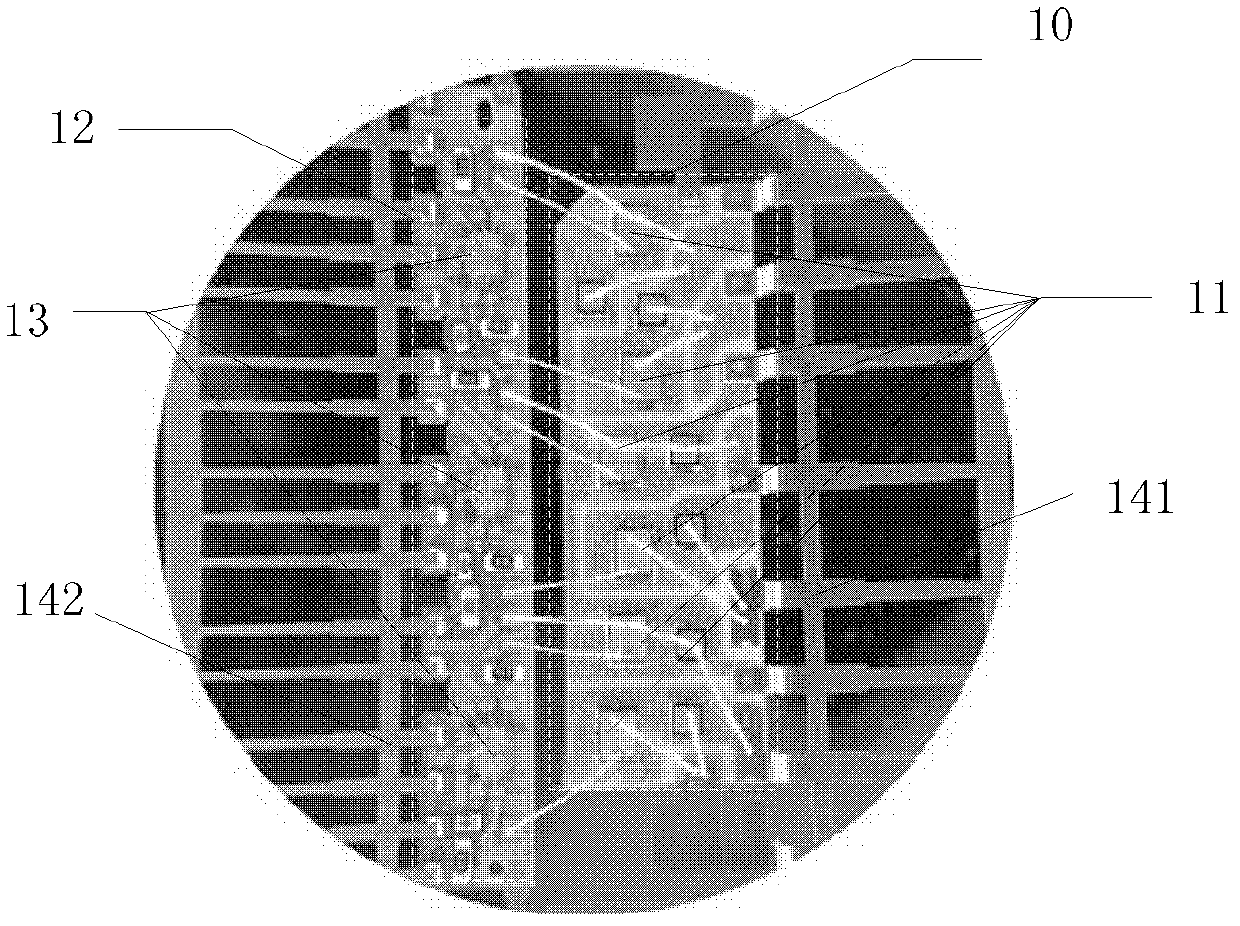

[0040] Attached below Figure 1-4 , the specific embodiment of the present invention will be further described in detail.

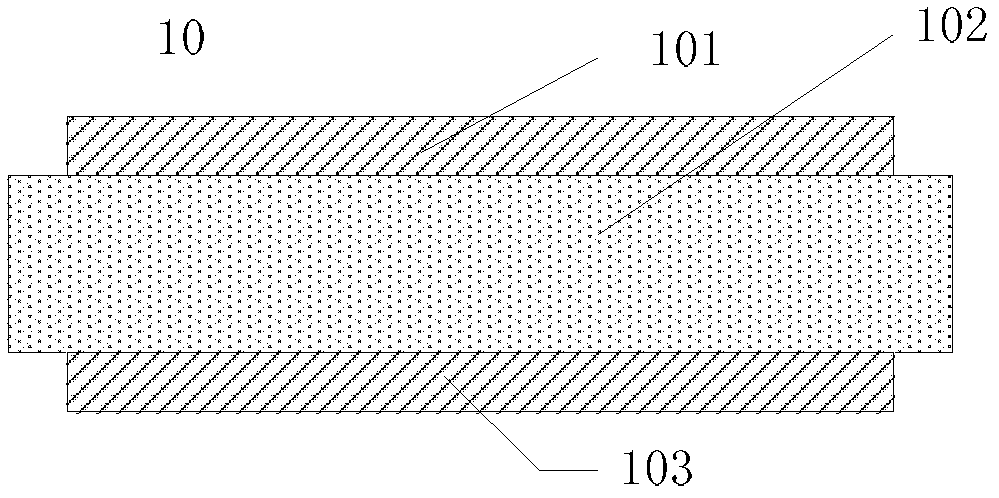

[0041]The power semiconductor module packaging structure based on the copper-clad ceramic substrate provided by the present invention is suitable for any power semiconductor module packaging structure that includes multiple power drive chips and frequency conversion control chips integrated in a compact physical volume and small external dimensions . Before introducing the present invention, first briefly introduce the copper-clad ceramic substrate.

[0042] Copper-clad ceramic substrate is made by directly bonding copper foil to the upper and lower surfaces of the ceramic substrate at high temperature. It has electrical insulation performance, high thermal conductivity and high mechanical strength. It not only has excellent solderability and High adhesion strength, and the coefficient of thermal expansion is close to that of silicon, it is an ideal sub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com