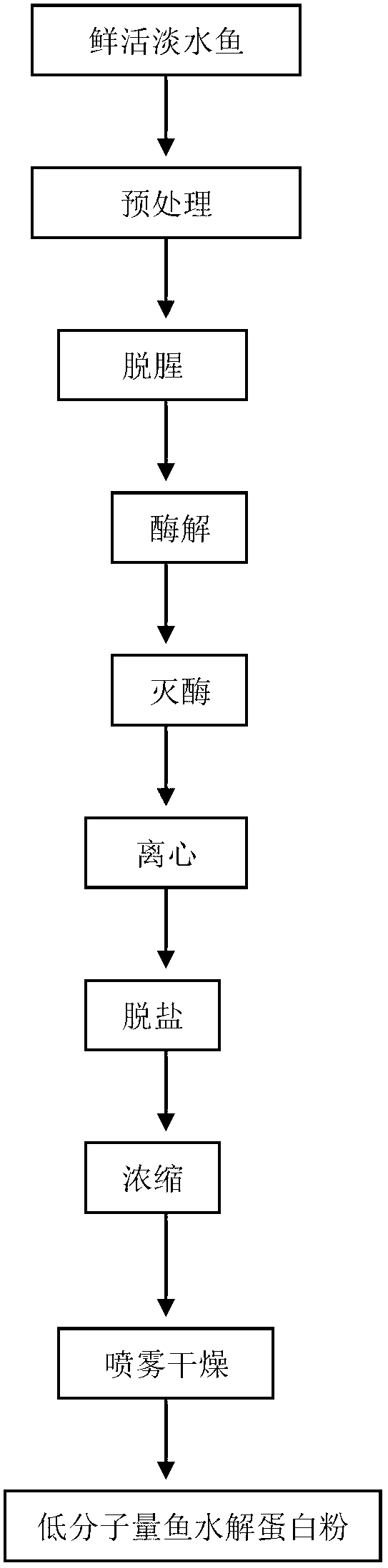

Preparation method for low-molecular-weight fish hydrolyzed protein powder

A low molecular weight, protein powder technology, applied in the direction of fish protein composition, protein food composition, food science, etc., can solve the problem that protein powder solubility protein powder has a great influence on the application range, low molecular weight high solubility protein powder is in a blank state, etc. problems, to achieve the effect of promoting benign development, no toxic side effects, and easy digestion and absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

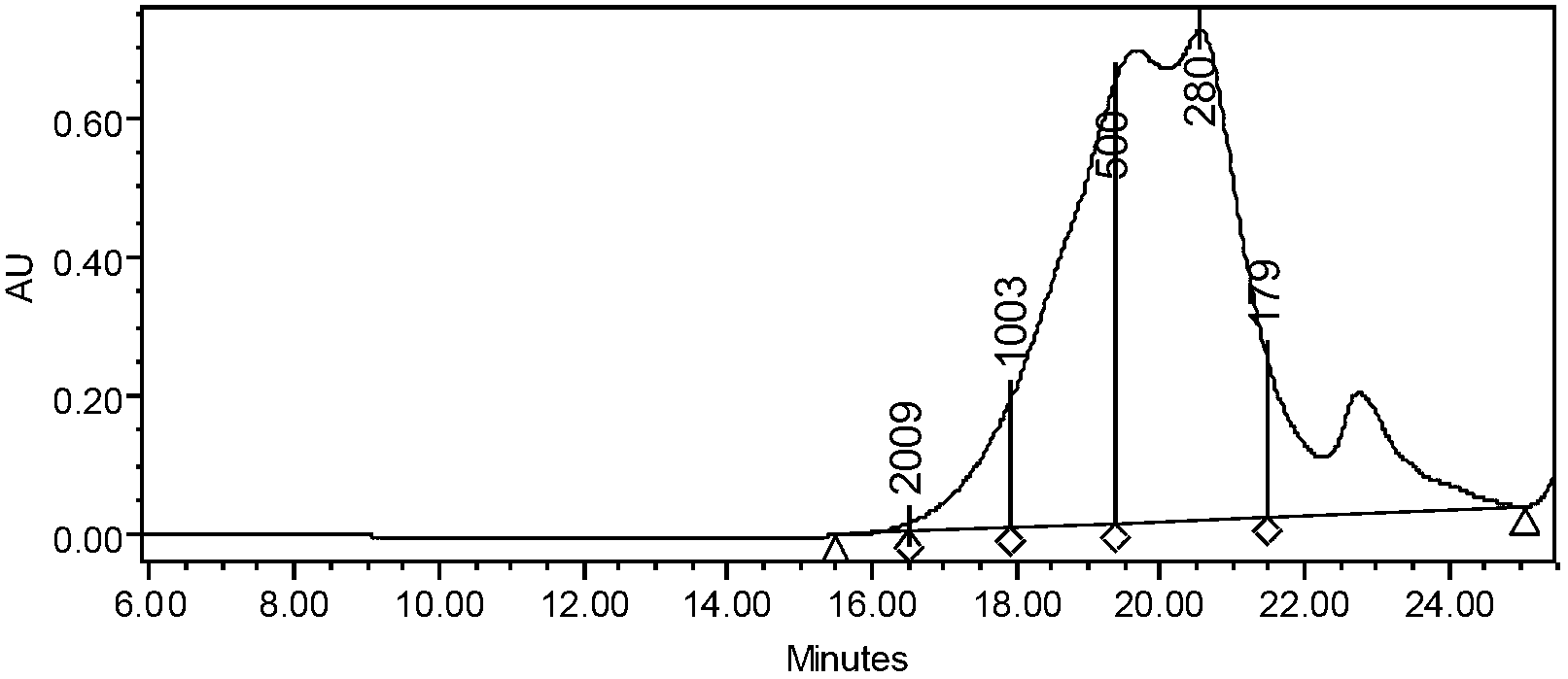

Embodiment 1

[0022] Choose fresh silver carp, kill the fish, remove the scales, viscera, head, and wash. After the meat is harvested by the meat harvester, take 1kg of minced fish, add 2kg of distilled water, and then add 30-50g of ginger juice. Keep warm at 100°C, stir for 10-15 minutes to remove the fishy smell, and get the fishy fish paste; cool the fishy fish paste to 50-55°C and keep it warm, add 3000-4000U / g papain according to the protein of the fish meat, stir, and use the pH-stat method Keep the pH stable at 6.0-6.5, and react at a constant temperature for 3-4 hours; control the degree of hydrolysis of the proteolysis solution of fish meat to 25%-30%. After the reaction is completed, raise the temperature to 90-100°C and keep it warm for 10-15 minutes to inactivate the enzyme; after cooling to room temperature, centrifuge at 5000r / min for 10-20 minutes, and the supernatant is the fish protein hydrolyzate; select nanofiltration desalination, before desalination The conductivity is ...

Embodiment 2

[0024] Choose fresh and live bighead carp, after slaughtering the fish, remove the scales, viscera, head, and wash. After the meat is harvested by the meat harvester, take 1kg of minced fish, add 2kg of distilled water, and then add 30-50g of ginger juice, 90-50g Keep warm at 100°C, stir for 10-15 minutes to remove the fishy smell, and get the fishy fish paste; cool the fishy fish paste to 50-55°C and keep it warm, add 3000-4000U / g Alcalase enzyme according to the fish meat protein, stir, and use the pH-stat method Keep the pH stable at 8.5-9.0, and react at a constant temperature for 3-4 hours; control the hydrolysis degree of the proteolysis solution of fish meat to 25%-30%. After the reaction is completed, raise the temperature to 90-100°C and keep it warm for 10-15 minutes to inactivate the enzyme; after cooling to room temperature, centrifuge at 5000r / min for 10-20 minutes, and the supernatant is the fish protein hydrolyzate; select nanofiltration desalination, before desa...

Embodiment 3

[0026]Choose fresh herring, kill the fish, remove the scales, viscera, head, and wash. After the meat is harvested by the meat harvester, take 1kg of fish mince, add 2kg of distilled water, and then add 30-50g of ginger juice, 90-100 Keep warm at ℃, stir for 10-15 minutes to remove the fishy smell, and get the fishy fish paste; cool the fishy fish paste to 50-55°C and keep it warm, add 3000-4000U / g neutral protease according to the fish meat protein, stir, and use the pH-stat method Keep the pH stable at 6.5-7.5, and react at a constant temperature for 3-4 hours; control the degree of hydrolysis of the proteolysis liquid of fish meat to 25%-30%. After the reaction is completed, raise the temperature to 90-100°C and keep it warm for 10-15 minutes to inactivate the enzyme; after cooling to room temperature, centrifuge at 5000r / min for 10-20 minutes, and the supernatant is the fish protein hydrolyzate; select nanofiltration desalination, before desalination The conductivity is ab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com