A stable method for microencapsulating carotenoid

A carotenoid, stable technology, applied in the field of carotenoid granule or powder preparation, can solve the problems of carotenoid loss, affect the effective absorption of animals, waste of temperature and energy, etc., achieve good water dispersibility, significant coloring effect, extremely easily dispersed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0036] A kind of microencapsulation method of stable carotenoid is carried out according to the following steps:

[0037] 1. Completely dissolve 33.5g gelatin, 43.3g sucrose, 1.5g Vc palmitate and 0.2g EDTA into 100.0g water to form a uniform water phase A, and adjust the pH to 10.0-10.5 with 20% NaOH solution.

[0038] 2. Dissolve 18.0 g of canthaxanthin crystals, 3.0 g of ethoxyquin, and 0.5 g of VE oil in 360.0 g of dichloromethane, stir until completely dissolved, and obtain oil phase B.

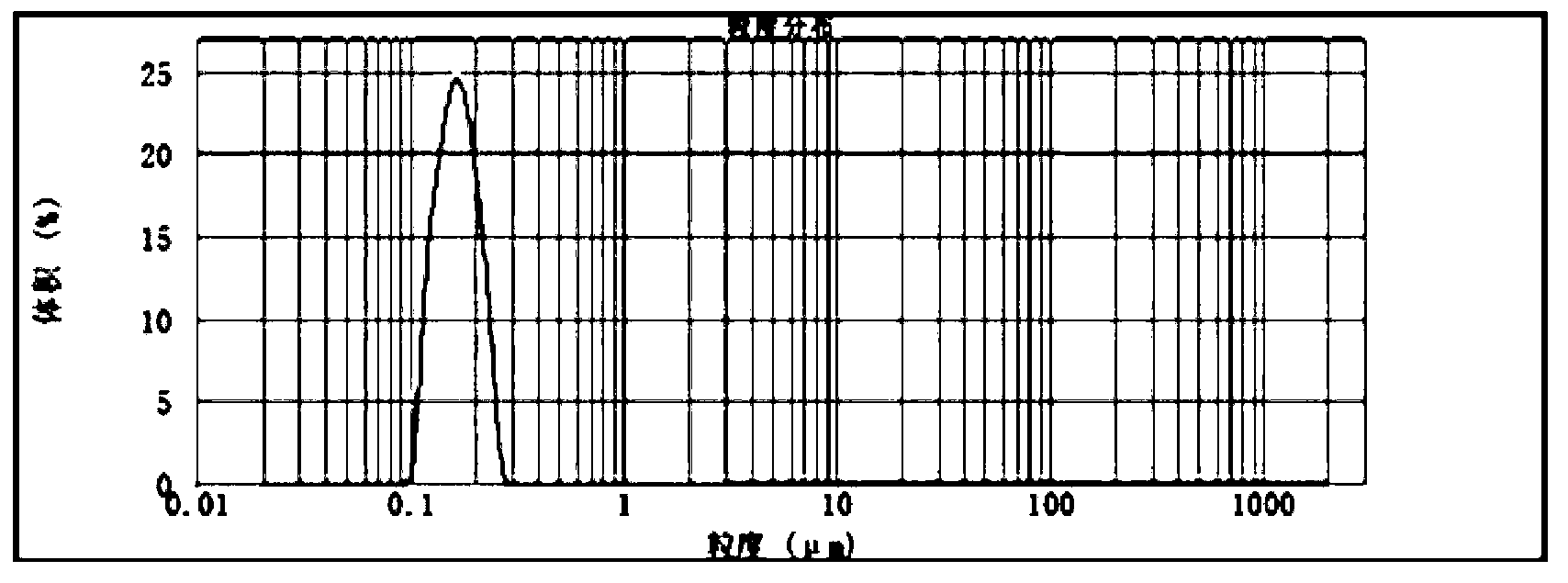

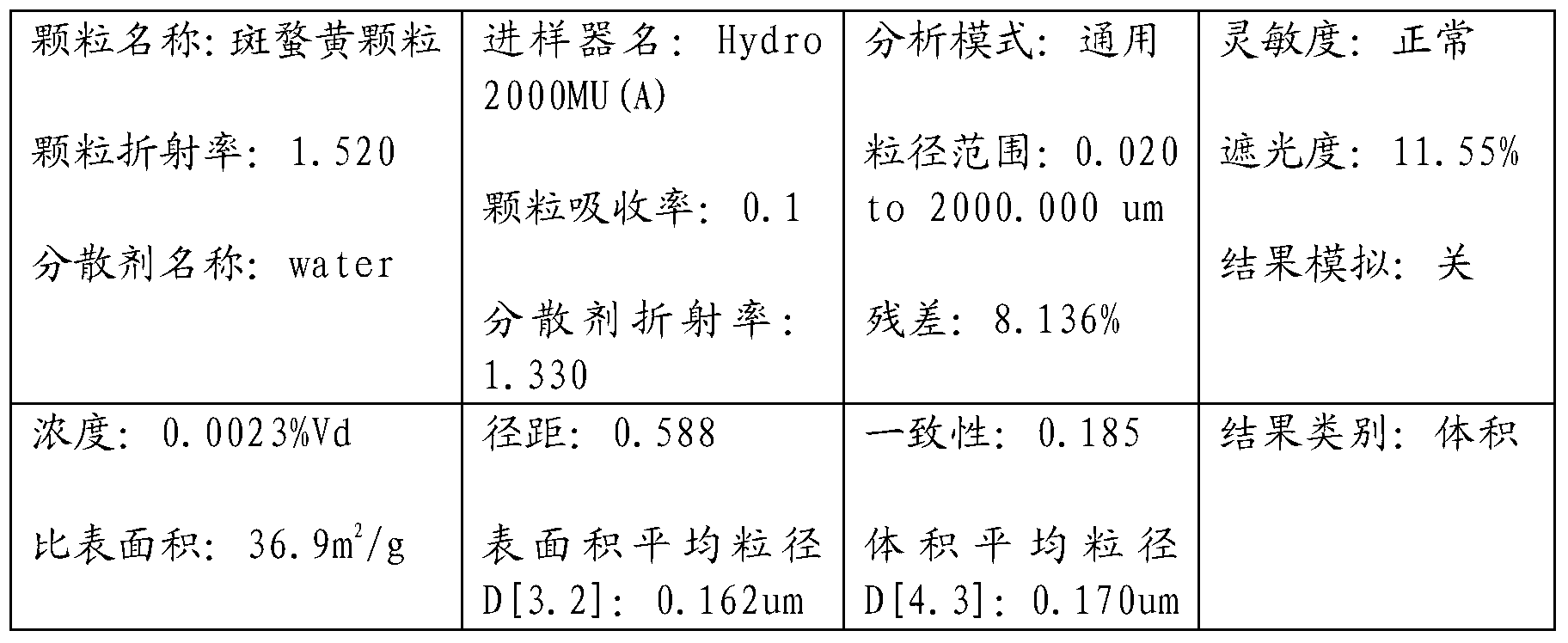

[0039] 3. Under high stirring and high shear conditions, add oil phase B to water phase A, then emulsify at a stirring speed of 2900-18000rpm for 15 minutes, then raise the temperature to 50°C to remove the solvent and form a microemulsion. Wherein, the obtained microemulsion is a sub-nanometer microemulsion, its average particle diameter is 130-200nm, and the pH of the microemulsion is 9-10; high stirring and high shearing refers to: the shearing power is 0.5-100Kw, stirring The speed ...

specific Embodiment 2

[0045] 1. Dissolve 33.5g of gelatin, 51.g of sucrose, 1.5g of Vc palmitate, and 0.2g of EDTA into 100.0g of water to form a uniform water phase. Adjust the pH to 10.0-10.5 with 20% NaOH solution.

[0046] 2. Dissolve 10.5g of β-carotene crystals, 1.0g of BHT, and 2.0g of VE oil in 210.0g of chloroform, and stir until completely dissolved.

[0047] 3. Under high stirring and high shear conditions, add oil phase B to water phase A, then emulsify at a stirring speed of 2900-18000rpm for 15 minutes, then raise the temperature to 50°C to remove the solvent and form a microemulsion. Wherein, the obtained microemulsion is a sub-nanometer microemulsion, its average particle diameter is 130-200nm, and the pH of the microemulsion is 9-10; high stirring and high shearing refers to: the shearing power is 0.5-100Kw, stirring The speed is 2900-18000 rpm.

[0048] 4. Spray-dry the microemulsion to make β-carotene particles.

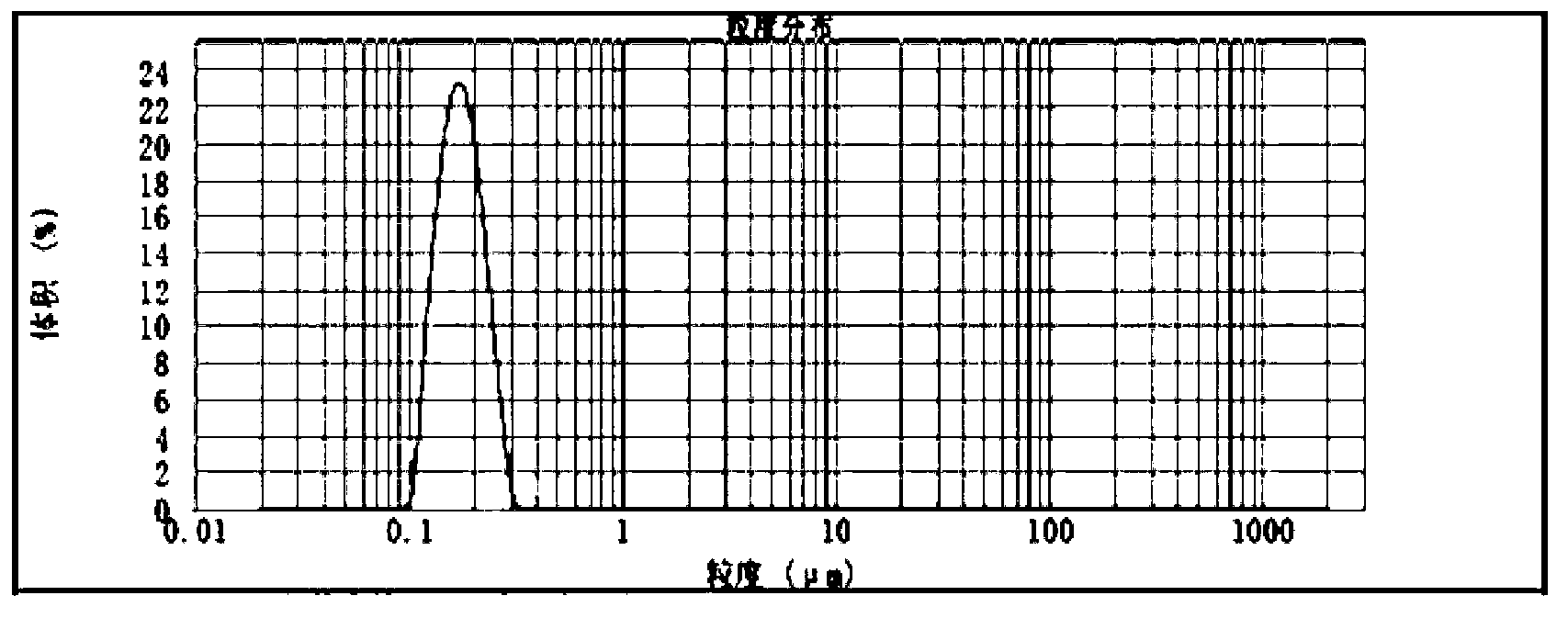

[0049] Refer to Table 2 and figure 2 , in the β-carotene granu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com