Production method for sodium pyroantimonate by using high-temperature high-pressure pure-oxygen oxidation

A technology of sodium pyroantimonate, high temperature and high pressure, applied in chemical instruments and methods, inorganic chemistry, antimony compounds, etc., can solve the problems of high anticorrosion requirements for equipment, poor production conditions, product quality fluctuations, etc., and achieve product quality and stability, Mild reaction conditions and stable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

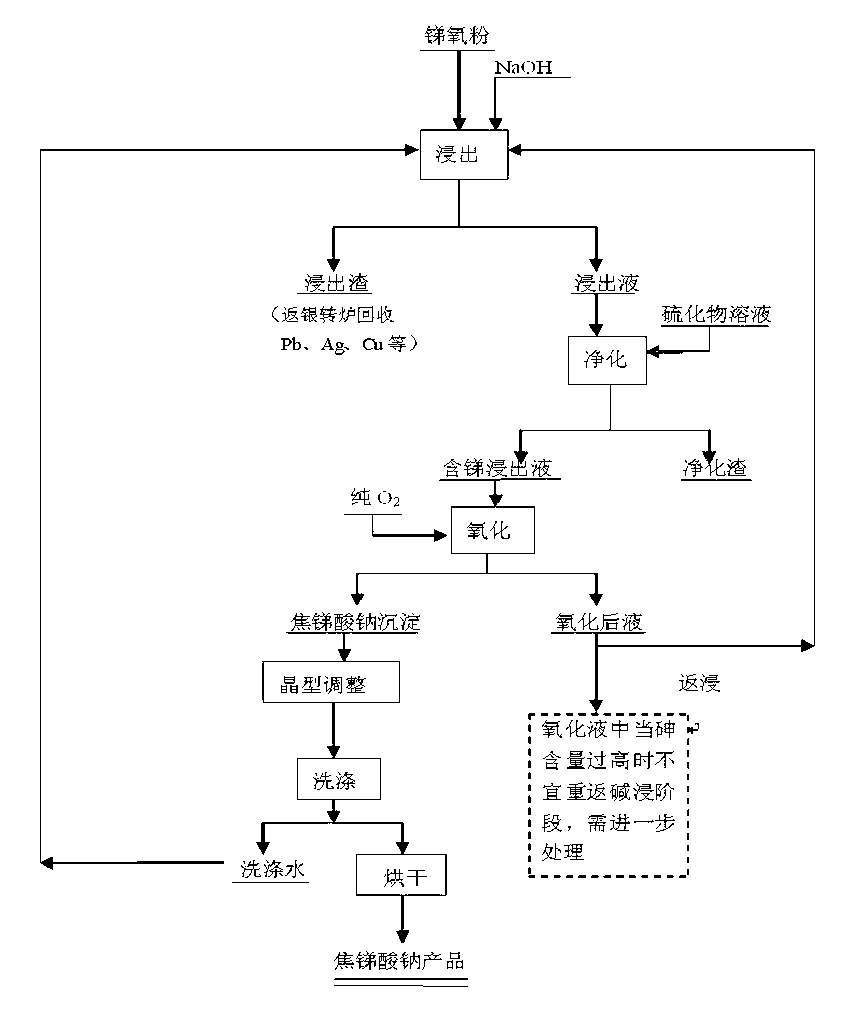

Method used

Image

Examples

Embodiment 1

[0019] Add 2000 mL of sodium hydroxide (300 g / L) solution to 200 g of antimony oxide powder containing 52.25% antimony and 13.21% lead, stir at 85°C for 60 min, and then add the purifying agent Na 2 S (55 g / L) solution 5 mL was used to remove impurities, filtered for 60 min after purification, the filtrate was moved to an autoclave, and oxygen was introduced, the temperature was controlled at 120 °C, and the pressure was adjusted and maintained at 1.5 MPa. After 60 min of reaction, antimony The precipitation rate reached 99.15%. After filtration, washing, drying and crushing, 172.6 g of sodium pyroantimonate product was obtained. Product quality analysis results are: Sb: 49.17%; Na 2 O: 12.73%; Pb: 0.0012%; As: 3+ : 0.09%, the appearance color is white, in line with the national standard.

Embodiment 2

[0021] Add 3000 mL of sodium hydroxide (400 g / L) solution to 200 g of antimony oxide powder containing 48.65% antimony and 14.08% lead, stir at 95 °C for 60 min, and then add the purifying agent Na 2 Remove impurities with 5 ml of S (55 g / L) solution, filter after purification for 60 min, move the filtrate to an autoclave, feed oxygen, control the temperature at 150 °C, adjust and maintain the pressure at 2.5 MPa, and react for 50 min, antimony precipitates The yield reached 99.5%, filtered, washed, dried, and pulverized to obtain 161.4 g of sodium pyroantimonate product. Product quality analysis results are: Sb: 49.31%; Na 2 O: 12.47%; Pb: 0.001 1%; As: 3+ : 0.05%, the appearance color is white, in line with the national standard.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com