Low-phosphorous environment-friendly composite scale and corrosion inhibitor

A scale and corrosion inhibitor, an environmentally friendly technology, applied in the field of industrial circulating water treatment, can solve the problem that water cannot be recycled directly, and achieve the effect of enhancing scale and corrosion inhibition, inhibiting scale formation, and preventing corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

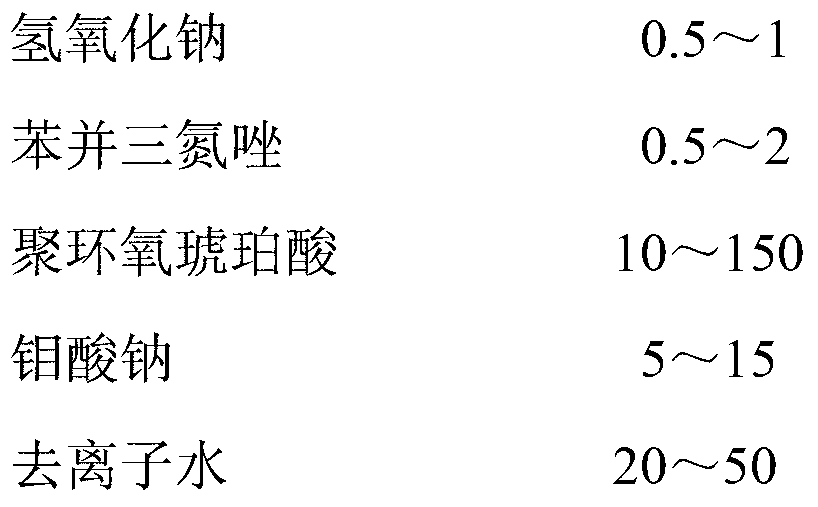

[0039] 1) Dissolve 6g of sodium hydroxide in 24g of deionized water, then add 10g of benzotriazole into the aqueous solution of sodium hydroxide, and perform sufficient conventional stirring to completely dissolve it for later use;

[0040] 2) Add 260g of deionized water with a water temperature of 50-60 degrees to 100g of polyepoxysuccinic acid and stir evenly, then add 100g of sodium molybdate, and carry out regular stirring to completely dissolve the sodium molybdate for later use;

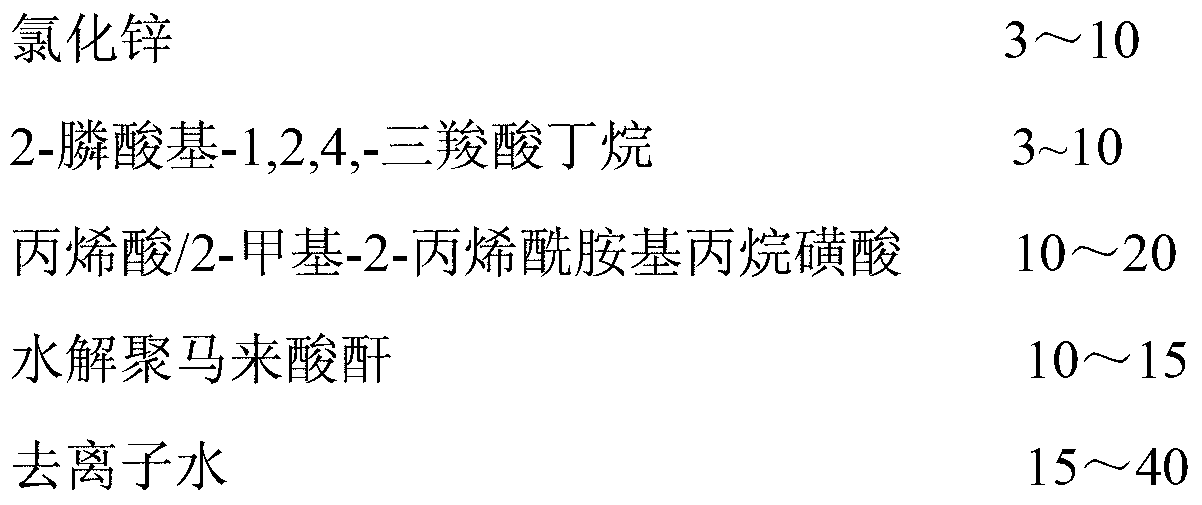

[0041] 3) Add 50g of zinc chloride to 144g of deionized water, stir to dissolve it, then add 50g of 2-phosphonic acid-1,2,4,-butane tricarboxylate, and stir to make it evenly mixed for later use ;

[0042]4) Add 100g of acrylic acid / 2-acrylamide-2-methylpropanesulfonic acid into 50g of deionized water, carry out regular stirring, and then add 100g of hydrolyzed polymaleic anhydride.

[0043] 5) Add 1) to 2) for regular stirring, fully mix to form component A, add 3) to 4) for regular stirring,...

Embodiment 2

[0045] 1) Dissolve 4g of sodium hydroxide in 24g of deionized water, then add 12g of benzotriazole into the aqueous solution of sodium hydroxide, and carry out sufficient conventional stirring to completely dissolve it for later use;

[0046] 2) Add 260g of deionized water with a water temperature of 50-60 degrees to 10g of polyepoxysuccinic acid and stir evenly, then add 60g of sodium molybdate, and carry out regular stirring to completely dissolve the sodium molybdate for later use;

[0047] 3) Add 20g of zinc chloride to 144g of deionized water, stir to dissolve it, then add 50g of 2-phosphonic acid-1,2,4,-butane tricarboxylate, and stir to make it evenly mixed for later use ;

[0048] 4) Add 40g of acrylic acid / 2-acrylamide-2-methylpropanesulfonic acid to 50g of deionized water, carry out conventional stirring, and then add 30g of hydrolyzed polymaleic anhydride.

[0049] 5) Add 1) to 2) for regular stirring, fully mix to form component A, add 3) to 4) for regular stirrin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com