Environment-friendly preparation method of phosphorus flame retardant, namely 2-(diphenylphosphinoyl)-1, 4-benzenediol

A technology of diphenylphosphono and phosphorus-based flame retardants, applied in chemical instruments and methods, compounds of Group 5/15 elements of the periodic table, organic chemistry, etc., can solve the problem of low product yield and complicated purification process , high toxicity and other problems, to achieve the effect of high yield, simple purification and less by-products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

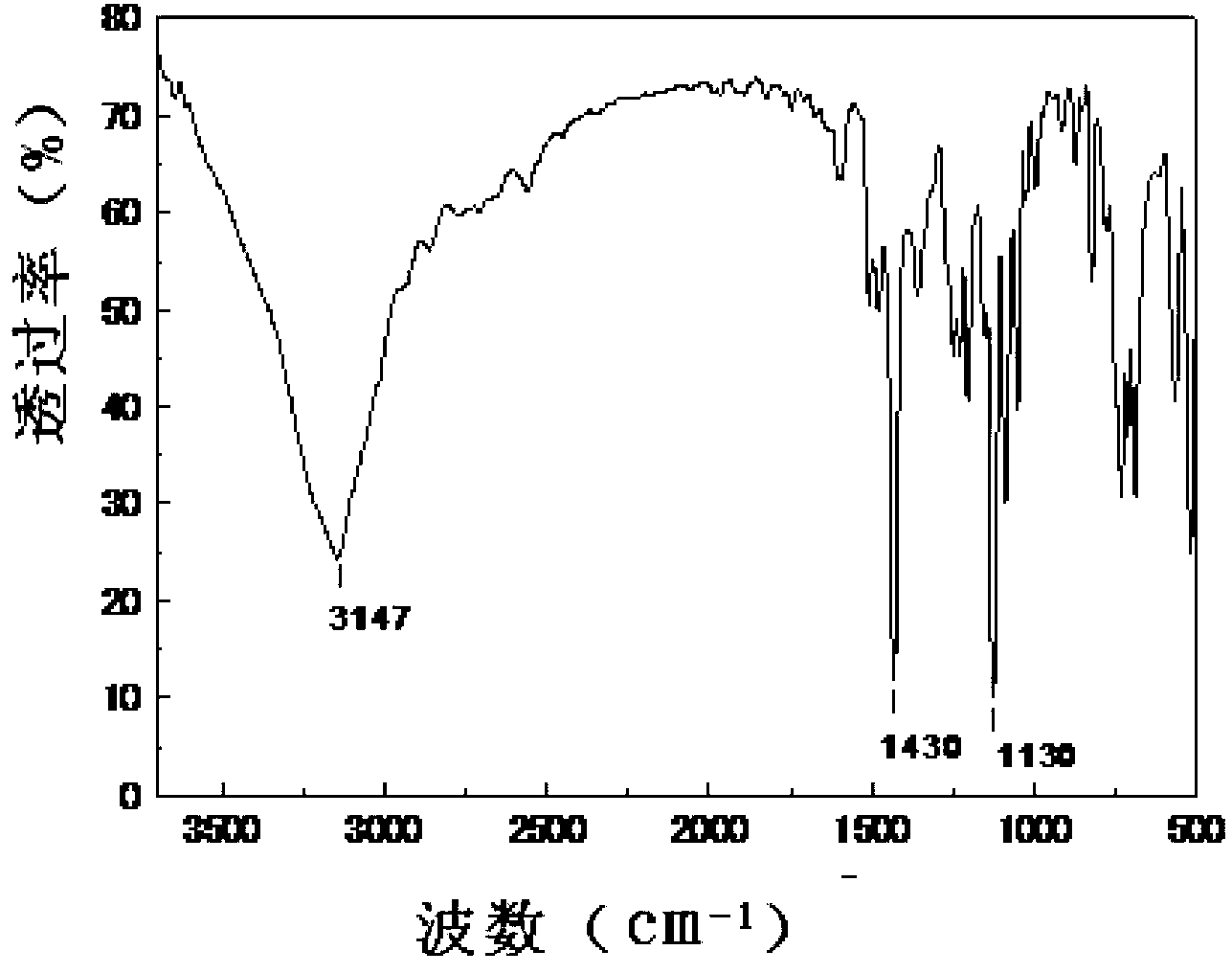

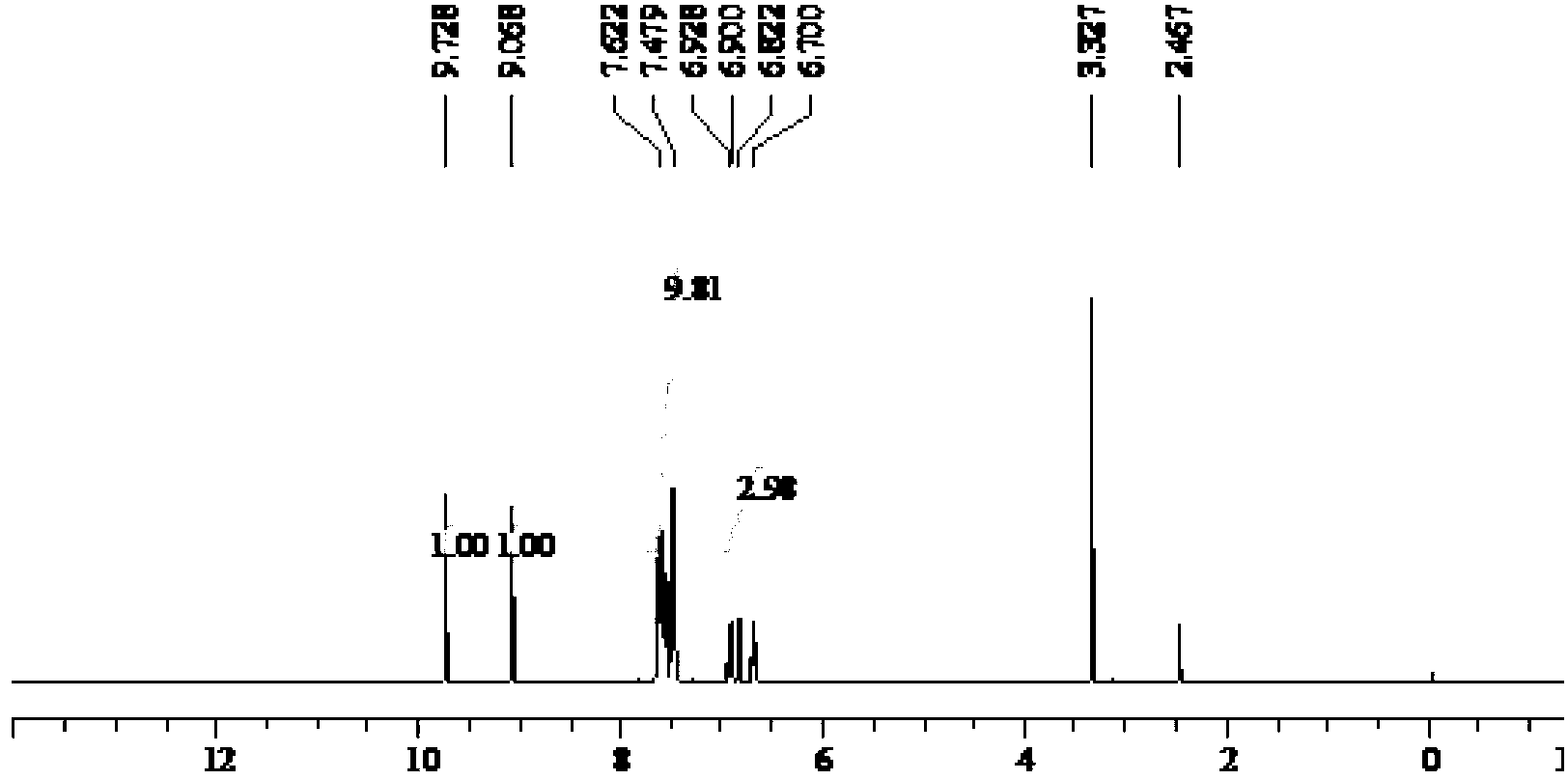

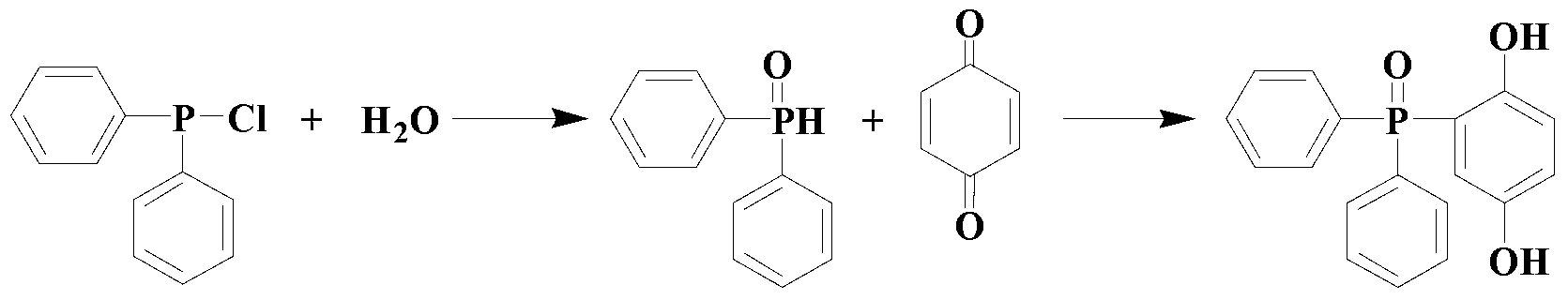

[0021] Equipped with mechanical stirring, thermometer, reflux condenser, N 2 In the 250ml dry four-necked flask of the catheter, feed dry nitrogen to remove the air in the flask, then add 22.0g (0.1mol) diphenylphosphine oxide, drop 1.8g (0.1mol) water at room temperature, and react at room temperature for 1 hour , then slowly add 50g of absolute ethanol and 10.8g (0.1mol) of p-benzoquinone mixture, react at room temperature for 2 hours, filter to obtain light yellow solid powder, then wash with 50g of absolute ethanol under reflux for 0.5 hour, cool Filter to obtain white solid powder, i.e. the product 2-(diphenylphosphono)-1,4-benzenediol, the yield is 81%, the infrared spectrum and NMR spectrum of the product are shown in figure 1 and figure 2 ;

Embodiment 2

[0023] Embodiment 2 has changed the proportioning of diphenylphosphine chloride and water, and concrete synthetic technique is as follows:

[0024] Equipped with mechanical stirring, thermometer, reflux condenser, N 2 In the 250ml dry four-necked flask of the catheter, feed dry nitrogen to remove the air in the flask, then add 22.0g (0.1mol) diphenylphosphine oxide, add 2.7g (0.15mol) water dropwise at room temperature, and react at room temperature for 1 hour , and then slowly add 50g of absolute ethanol and 10.8g (0.1mol) of p-benzoquinone mixture, react at room temperature for 2 hours, filter to obtain light yellow solid powder, then wash 0.5 pieces with 50g of absolute ethanol under reflux hours, cooled, filtered, and dried to obtain a white solid powder, the product 2-(diphenylphosphono)-1,4-benzenediol, with a yield of 94%.

Embodiment 3

[0026] Embodiment 3 has changed the proportioning of diphenylphosphine chloride and water, and concrete synthetic technique is as follows:

[0027] Equipped with mechanical stirring, thermometer, reflux condenser, N 2 In the 250ml dry four-necked flask of the catheter, feed dry nitrogen to remove the air in the flask, then add 22.0g (0.1mol) diphenylphosphine oxide, add 3.6g (0.2mol) water dropwise at room temperature, and react at room temperature for 1 hour , and then slowly add 50g of absolute ethanol and 10.8g (0.1mol) of p-benzoquinone mixture, react at room temperature for 2 hours, filter to obtain light yellow solid powder, then wash 0.5 pieces with 50g of absolute ethanol under reflux hours, cooled, filtered, and dried to obtain a white solid powder, the product 2-(diphenylphosphono)-1,4-benzenediol, with a yield of 95%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com