Self-cleaning type aluminum-plastic composite panel and manufacturing method thereof

An aluminum-plastic composite board, self-cleaning technology, applied in chemical instruments and methods, synthetic resin layered products, lamination, etc., can solve problems such as easy adhesion, danger, and difficult cleaning work, and achieve anti-pollution ability Strong, improve service life, save maintenance cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below in conjunction with the accompanying drawings.

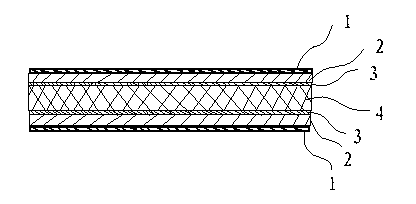

[0015] Such as figure 1 As shown, a self-cleaning aluminum-plastic composite board, the structure of the aluminum-plastic composite board is: it is composed of an aluminum panel base layer 2 and a PE plastic core layer 4, and there is a gap between the aluminum panel base layer 2 and the PE plastic core layer 4. A polymer film bonding layer 3 is provided, and an anti-pollution paint layer 1 and a transparent nano-paint layer are provided on the outer surface of the base layer 2 of the aluminum panel. The paint layer 1 is made of a fluorocarbon baking varnish material, and the fluorocarbon baking varnish material is The color can be selected and adjusted according to the decoration needs. The aluminum panel base layer 2, the polymer film adhesive layer 3 and the PE plastic core layer 4 are combined to form an aluminum-plastic board base material, and the paint...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com