Alkaline powder for treating leaked hydrogen sulfide poisonous gas and production method thereof

A hydrogen sulfide and powder technology, which is applied in chemical instruments and methods, separation methods, and dispersed particle separation, can solve the problems of reducing the specific surface area of powders, reducing the efficiency of adsorption reactions, and increasing the risk of environmental pollution, so as to achieve fluffy residues and easy Cleaning or removal by negative pressure suction, fast response effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

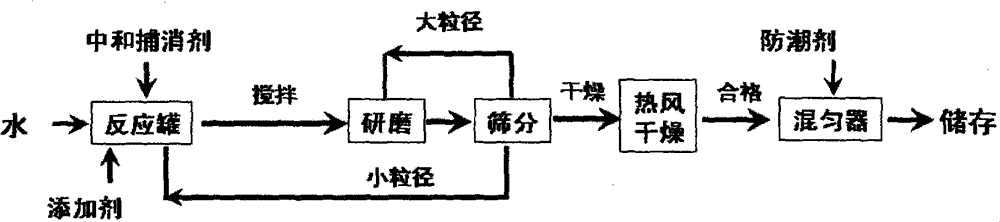

[0037] Example 1 Preparation and application of hydrogen sulfide leakage disposal powder

[0038] Prepare 100kg of alkaline powder for disposal of hydrogen sulfide leakage, and its composition ratio is: neutralization catcher (calcium hydroxide 46.75kg, sodium hydroxide 23.375kg, potassium hydroxide 23.375kg) 93.5kg, moisture-proof agent 0.5kg , Additives 6kg. The specific preparation method is as follows: firstly, the additive and the neutralizing and arresting agent are sequentially mixed in a reaction tank with a stirring device, stirred for 0.5h to 1h, added with 5% to 50% of clean water, stirred for 1h, and subjected to grinding and primary sieving to make the The part that meets the particle size requirements (60 mesh ~ 160 mesh) is sent to a hot air dryer for drying. When the moisture content is less than 1%, it is sent to a mixer, and a moisture-proof agent is added for mixing to meet the requirements of particle size, specific surface area and bulk density. Qualified...

Embodiment 2

[0040] Example 2 Preparation and application of hydrogen sulfide leakage disposal powder

[0041] Prepare 100kg of alkaline powder for treating hydrogen sulfide leakage, and its composition ratio is: 90kg of neutralizing and arresting agent (18kg of calcium carbide slag, 72kg of potassium hydroxide), 2kg of moisture-proof agent, and 8kg of additives. The specific preparation method is as follows: firstly, the additive and the neutralizing and arresting agent are sequentially mixed in a reaction tank with a stirring device, stirred for 0.5h to 1h, added with 5% to 50% of clean water, stirred for 1h, and subjected to grinding and primary sieving to make the The part that meets the particle size requirements (60 mesh ~ 160 mesh) is sent to a hot air dryer for drying. When the moisture content is less than 1%, it is sent to a mixer, and a moisture-proof agent is added for mixing to meet the requirements of particle size, specific surface area and bulk density. Qualified products; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Specific surface | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com