Carbonate phosphorite reverse flotation collecting agent and preparation method thereof

A technology of reverse flotation and collector, applied in flotation, solid separation and other directions, can solve the problems of high dosage and cost, low selectivity, poor dispersibility, etc., and achieve low raw material cost, low dosage, The effect of good flotation indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

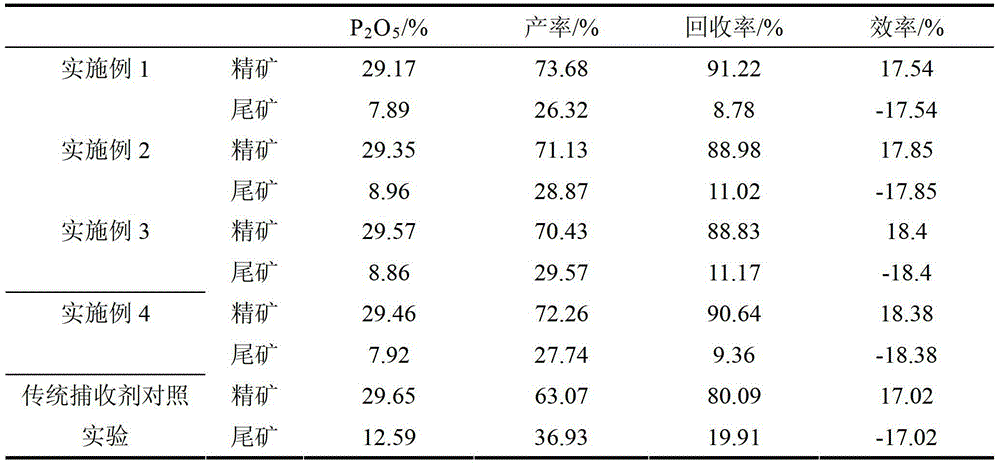

Examples

Embodiment 1

[0028] Take 1 part of cotton oil residue after hydroxylation (the hydroxylation reaction is based on the mass ratio of cotton oil residue and sodium hydroxide at a ratio of 1:0.3, and react at 180°C for 4 hours), and 0.6 parts of stearic acid in an autoclave , make 0.5 parts of sodium hydroxide into a solution of any solubility and slowly add it to the autoclave, disperse with appropriate amount of water, adjust the temperature of the reactor to 140 °C, wait for the temperature to stabilize and then react for 6 hours, weigh the product to calculate its solid content, adding water to prepare a solution with a solid content of 2wt% is the reverse flotation collector.

Embodiment 2

[0030] Take 1 part of the product of cotton oil residue after first chlorination and then hydroxylation (chlorination reaction is carried out at 100 °C, chlorine gas is excessive; in the hydroxylation reaction, the mass ratio of cotton oil residue to potassium hydroxide is 1:0.4, in 140°C reaction for 10h), 1 part of palmitic acid, 0.3 parts of modified fatty acid (obtained from industrial oleic acid through chlorination and then hydroxylation, the chlorination reaction is carried out at 100°C, chlorine gas is slightly excessive, and oleic acid is used during hydroxylation Reaction with potassium hydroxide mass ratio of 1:0.3) in the autoclave, make 0.2 parts of sodium hydroxide into a solution of any solubility, then slowly add it to the autoclave, disperse with appropriate amount of water, and adjust the temperature of the autoclave to 180 °C, react for 10 hours after the temperature stabilizes, weigh the product to calculate its solid content, and add water to make a 2wt% so...

Embodiment 3

[0032] Take 1 part of cotton oil residue, 0.8 part of stearic acid, and 0.1 part of modified fatty acid (obtained from industrial oleic acid through chlorination and then hydroxylation, the chlorination reaction is carried out at 100 ° C, chlorine gas is slightly excessive, and the hydroxylation reaction is based on oleic acid Mix with potassium hydroxide at a mass ratio of 1:0.3, react at 160°C for 6h) in an autoclave, make 0.3 parts of sodium hydroxide into a solution of any solubility, slowly add it to the autoclave, disperse with appropriate amount of water, Adjust the temperature of the reactor to 160°C, and react for another 7 hours after the temperature is stable, weigh the product to calculate its solid content, add water to make a 2wt% solution, and then use it as the reverse flotation collector.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com