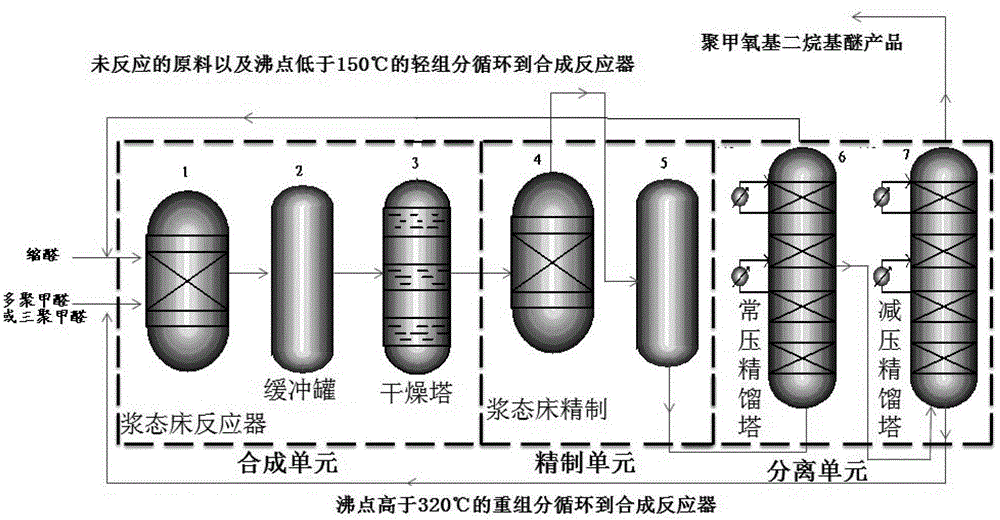

Method for conducting catalytic hydrofinishing of polyoxymethylene dialkyl ether through slurry reactor

一种聚甲醛二烷基醚、甲醛二烷基醚的技术,应用在浆态床催化加氢精制聚甲醛二烷基醚领域,能够解决提取产物纯度差等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

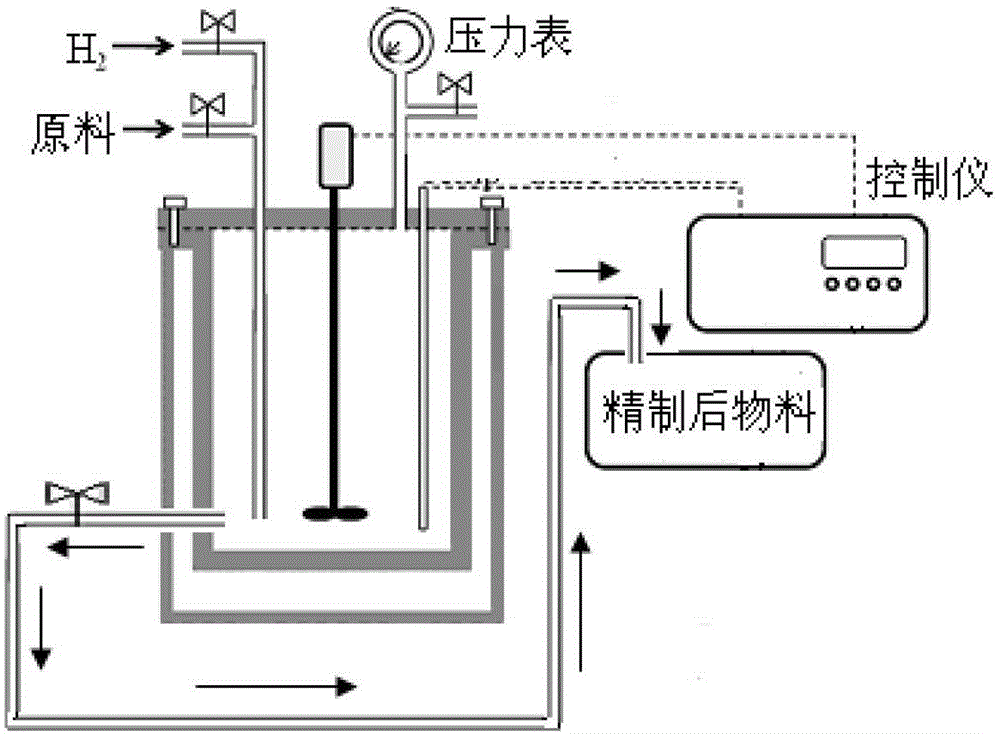

Method used

Image

Examples

Embodiment 1

[0046] First, 63g of Raney nickel Raney-Ni catalyst is loaded into a 2L pressurized slurry bed hydrofinishing reactor 4;

[0047] Then, 1260g of the equilibrium system containing polymethoxy dimethyl ether product is carried out catalytic hydrogenation refining, the usage amount of described Raney-Ni catalyst accounts for 5wt% of total reactant, and its technological condition is: hydrogen pressure 6Mpa, slurry State bed refining reaction temperature (i.e. hydrofining reaction temperature) 70°C, reaction time 4 hours;

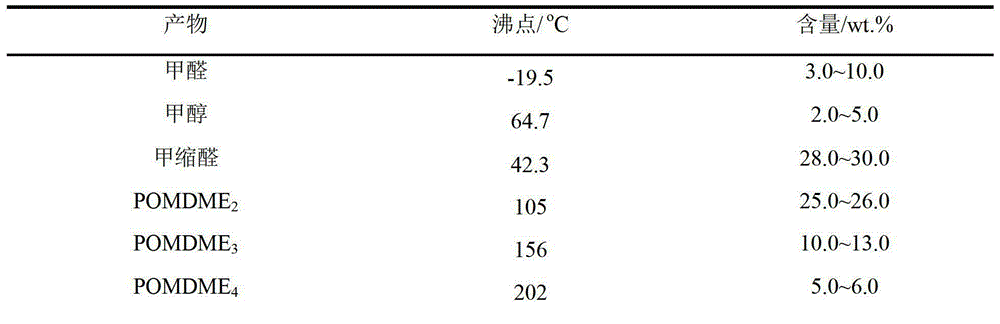

[0048] Finally, formaldehyde is hydrogenated under the action of the Raney-Ni catalyst to generate methanol, and the generated methanol is used as one of the equilibrium product components, so that no other foreign components are produced while removing formaldehyde. The composition and distribution are shown in Table 2.

[0049] The equilibrium system after catalytic hydrofining is extracted. The extraction process adopts atmospheric distillation technology, ...

Embodiment 2

[0051] First, load 37.8g of Raney-Cu catalyst into a 2L pressurized slurry bed hydrofinishing reactor;

[0052] Then, 1260g of the equilibrium system containing polymethoxy dimethyl ether product is carried out catalytic hydrogenation refining, the usage amount of described Raney-Cu catalyst accounts for 3wt% of total reactant, and its technological condition is: hydrogen pressure 2Mpa, slurry State bed refining reaction temperature (i.e. hydrofining reaction temperature) 110°C, reaction time 4.5 hours;

[0053] Finally, formaldehyde is hydrogenated under the action of the Raney-Cu catalyst to generate methanol, and the generated methanol is used as one of the equilibrium product components, so that no other foreign components are produced while removing formaldehyde. The composition of the main materials before and after catalytic hydrorefining And the distribution is shown in Table 2.

[0054] In this embodiment, the same extraction process as in Example 1 is used for extra...

Embodiment 3-1

[0066] First, load 63g of Raney-Cu catalyst into a 2L pressurized slurry bed hydrofinishing reactor;

[0067] Then, 1260g of the equilibrium system containing polymethoxydiethyl ether product is carried out catalytic hydrogenation refining, the usage amount of described Raney-Cu catalyst accounts for 5wt% of total reactant, and its technological condition is: hydrogen pressure 3Mpa, slurry State bed refining reaction temperature (i.e. hydrofining reaction temperature) 100°C, reaction time 5 hours;

[0068] Finally, formaldehyde is hydrogenated under the action of the Raney-Cu catalyst to generate methanol, and the generated methanol is used as one of the equilibrium product components, so that no other foreign components are produced while removing formaldehyde, and the main material before and after catalytic hydrorefining The composition and distribution are shown in Table 4-1.

[0069] The refined equilibrium system is extracted. The extraction process adopts atmospheric d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com