Reusable low-cost silica aerogel oil-absorbing sponge and preparation method thereof

A silicon aerogel, oil-absorbing sponge technology, applied in separation methods, chemical instruments and methods, liquid separation, etc., can solve the problems of low elasticity and strength of silicon aerogel, complicated and tedious operating conditions, and high environmental toxicity of raw materials, etc. Achieve the effect of shortening the production cycle, simple preparation tools, and good emergency response performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

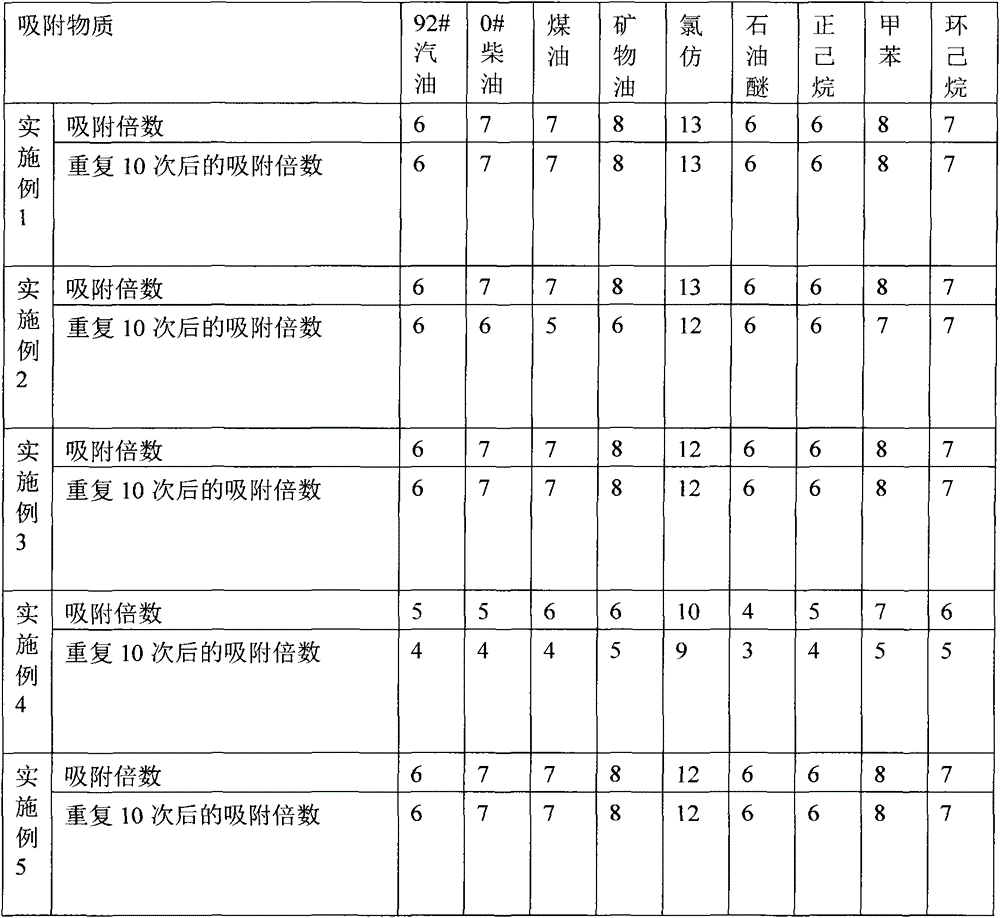

Examples

Embodiment 1

[0036] In a 100mL round-bottomed flask equipped with a magnetic stirring bar, add 2g of cetyltrimethylammonium chloride and 50mL of dilute acetic acid solution, and under vigorous stirring conditions, add 9mL of methyltrimethoxysilane and 5mL of dimethyl Dimethoxysilane. After reacting for 0.5h, add 5g of urea and continue stirring for 1h. The obtained airsilica precursor was transferred to an oven at 60°C, and kept for 6 hours. The obtained gel was washed 3 times by physical extrusion with 30 mL of methanol, and then dried at room temperature and normal pressure ventilation.

Embodiment 2

[0038] In a 100mL round bottom flask equipped with a magnetic stirring bar, add 2g of sodium dodecylbenzenesulfonate and 50mL of dilute acetic acid solution, and under vigorous stirring conditions, add 9mL of methyltrimethoxysilane and 8mL of dimethyldimethoxysilane in sequence Methoxysilane. After reacting for 0.5h, add 5g of urea and continue stirring for 1h. The obtained airsilica precursor was transferred to an oven at 60°C, and kept for 6 hours. The obtained gel was washed 3 times by physical extrusion with 30 mL of methanol, and then dried at room temperature and normal pressure ventilation.

Embodiment 3

[0040] In a 100mL round-bottomed flask equipped with a magnetic stirring bar, add 2g of cetyltrimethylammonium chloride and 50mL of dilute acetic acid solution, and under vigorous stirring conditions, add 9mL of methyltriethoxysilane and 5mL of diacetate Methyldiethoxysilane. After reacting for 0.5h, add 5g of urea and continue stirring for 1h. The obtained airsilica precursor was transferred to an oven at 60°C, and kept for 6 hours. The obtained gel was washed by physical extrusion with ethanol, and then dried in a ventilated place at room temperature and normal pressure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com