Halogen-free environment-friendly polystyrene flame retardant and preparation method thereof

A technology of polystyrene and flame retardants, which is applied in the field of halogen-free environmentally friendly flame retardants, can solve the problems of high cost and insufficient carbon layer structure strength, and achieve low pollution, suppression of melting dripping, and high flame retardancy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

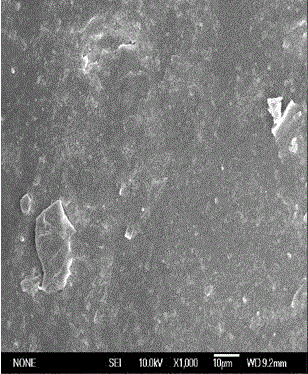

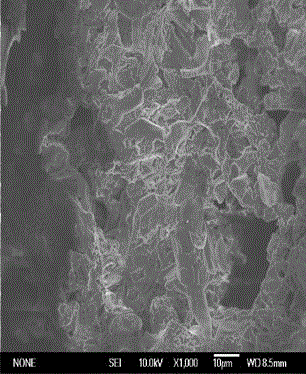

Image

Examples

specific Embodiment approach 1

[0018] Implementation of a polystyrene halogen-free environment-friendly flame retardant provided by the present invention, the composition and content of the halogen-free environment-friendly flame retardant are as follows in parts by mass:

[0019] 30-70 parts of ammonium polyphosphate, the ammonium polyphosphate is type II ammonium polyphosphate, the degree of polymerization is n≥1000, and the particle size is 80-200 mesh.

[0020] 10-50 parts of expanded graphite, the expanded graphite is 80-200 mesh, and the expansion multiple is 0.15-0.25 m3 / kg.

[0021] The calcium carbonate of 10~25 parts, described calcium carbonate is light calcium carbonate.

[0022] 3 to 5 parts of a char formation accelerator, the char formation accelerator being one of zinc oxide, zinc borate, and magnesium oxide.

[0023] 0.5-3 parts of surfactant, the surfactant is one of silane coupling agents KH550 and KH570.

[0024] Based on the above technical scheme, it is further preferred to implement...

specific Embodiment approach 2

[0026] Implement the preparation method of above-mentioned a kind of polystyrene halogen-free environment-friendly flame retardant of the present invention, this preparation method is to take raw material by a kind of polystyrene halogen-free environment-friendly flame retardant weight part, and ammonium polyphosphate, expanded graphite, Calcium carbonate and char formation accelerator are added to a high-speed mixer, heated to 90~130°C, mixed at a high speed of 800~1200r / min for 3~5min, mixed into a compound flame retardant, and then added into a compound flame retardant 1~3% of the total mass of the surfactant, continue to mix at high speed for 5~8min, and then the polystyrene halogen-free environmentally friendly flame retardant is obtained.

[0027] Realize the preparation method of the above-mentioned polystyrene halogen-free environment-friendly flame retardant, the preparation method can effectively reduce the invalid expansion of expanded graphite caused by high tempera...

Embodiment 1

[0030] A halogen-free environmentally friendly flame retardant applied to polystyrene, the flame retardant is made of the following raw materials in parts by weight: 55 parts of ammonium polyphosphate (APP), 25 parts of expanded graphite (EG), calcium carbonate (CaCO 3 ) 15 parts, magnesium oxide (MgO) 5 parts, silane coupling agent (KH570) 3 parts.

[0031] A kind of preparation method of the above-mentioned halogen-free environment-friendly flame retardant applied to polystyrene, the method is to weigh the raw materials according to the above-mentioned parts by weight, add ammonium polyphosphate, expanded graphite, calcium carbonate, magnesium oxide into the high-speed mixer, and heat up to Mix at 130°C for 5 minutes at a speed of 800r / min at a high speed to form a compound flame retardant, then add silane coupling agent KH570 of 2% of the total mass of the compound flame retardant, and continue to mix at a high speed for 8 minutes to obtain polyphenylene Halogen-free enviro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com