Water-based aluminum silver paste and preparation method thereof

An aluminum-silver paste, water-based technology, used in pigment paste, dyeing organosilicon compound treatment, fibrous fillers, etc. effect reduction and other problems, to achieve the effect of maintaining metallic luster, reducing light reflection, and improving transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] The embodiment of the present invention discloses a preparation method of water-based aluminum-silver paste, comprising the following steps:

[0023] a) Mix oily aluminum silver paste, organic solvent, silane coupling agent and water, and separate the solid mixture from the solvent after the silane coupling agent is hydrolyzed;

[0024] b) mixing the solid mixture, water and an organic solvent, and adjusting the pH to 7-8 to obtain a mixed solution;

[0025] c) mixing the mixed liquid, silane coupling agent and ethyl orthosilicate, and aging after reaction to obtain water-based aluminum silver paste.

[0026] The invention provides a preparation method of water-based aluminum-silver paste. In the process of preparing the water-based aluminum-silver paste, the present invention first uses a silane coupling agent to pretreat the oily aluminum-silver paste. The silane coupling agent is hydrolyzed to generate SiOH, and Si-OH is dehydrated and condensed to generate Si-OH-co...

Embodiment 1

[0039] (1) In the dispersion tank, disperse 100kg of oily aluminum silver paste in 250kg of isopropanol solvent, add 10kg of methyltrimethoxysilane, 6kg of water, after fully dispersed, separate solid and liquid to obtain filter cake and solution.

[0040] (2) Put the filter cake in the reaction kettle, add 300kg of isopropanol solvent, 8kg of water, keep the temperature at 40°C, fully disperse, and adjust the pH value of the solution to between 7 and 8 with ammonia water;

[0041] (3) Add 5kg of 3-aminopropyltrimethoxysilane and 3kg of ethyl orthosilicate dropwise.

[0042] The interval is 4h;

[0043] (4) Aging for 4 hours after the reaction, cooling, sieving, and pressure filtration to obtain water-based aluminum-silver paste;

[0044] (5) Adjust the solid content of the water-based aluminum-silver paste to 60wt%.

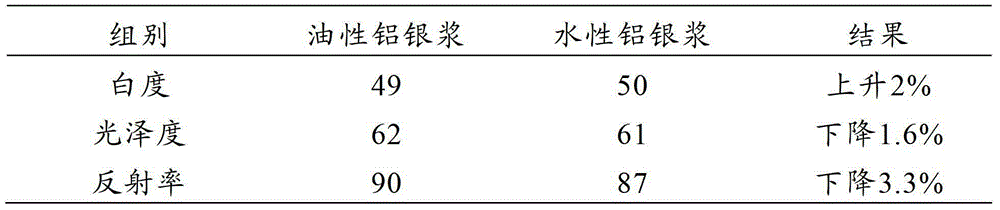

[0045] Mix 1 part by weight of oily aluminum-silver paste before coating and 1 part by weight of water-based aluminum-silver paste after coating with 1 part b...

Embodiment 2

[0049] (1) In the dispersion tank, disperse 100kg of oily aluminum silver paste in 250kg of ethanol solvent, add 10kg of methyltrimethoxysilane, 6kg of water, after fully dispersed, separate the solid and liquid to obtain the filter cake and solution;

[0050] (2) Put the filter cake in the reaction kettle, add 300kg of isopropanol solvent, 8kg of water, keep the temperature at 40°C, fully disperse, and adjust the pH value of the solution to between 7 and 8 with ammonia water;

[0051] (3) Add 5kg of 3-aminopropyltrimethoxysilane and 3kg of ethyl orthosilicate dropwise for 6 hours;

[0052] (4) Aging for 4 hours after the reaction, cooling, sieving, and pressure filtration to obtain water-based aluminum-silver paste;

[0053] (5) Adjust the solid content of the water-based aluminum-silver paste to 60wt%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com