Bucky paper electrocaloric effect-based fusion method and composite material thereof

A technology of carbon nano paper and electrothermal effect, which is applied in the bonding method of adhesive heating, etc., can solve the problems of solvent volatilization pollution, slow preparation speed, and high energy consumption, and achieve simple preparation method, fast preparation speed, and low energy consumption. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

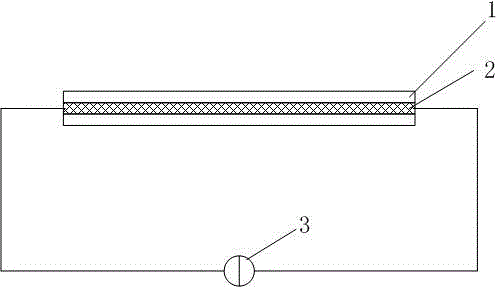

[0040] The magnesium-aluminum alloy sheet and the carbon nano-paper are laminated alternately, so that the whole is in a vacuum environment, and the carbon nano-paper is energized to reach 500°C, kept for 1 minute, and naturally cooled to obtain a carbon nano-reinforced magnesium-aluminum alloy composite material.

Embodiment 2

[0042] Attach a layer of polypropylene film to the carbon nano-paper, heat the carbon nano-paper to 170°C, apply a certain pressure between the polypropylene film and the carbon nano-tube paper, keep it for 5 seconds, and cool naturally to obtain Single sided polypropylene composite carbon nano paper.

Embodiment 3

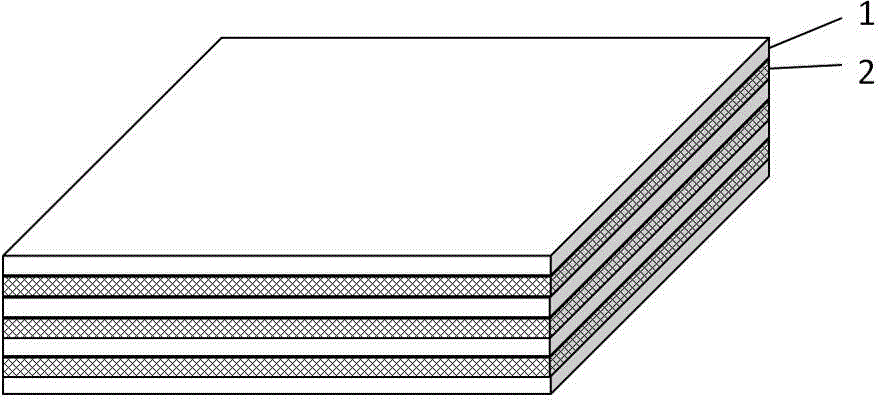

[0044] Alternately stick high-density polyethylene sheets and carbon nano papers in multiple layers so that the whole is in a vacuum environment, heat the carbon nano papers to 140°C, and apply a certain amount of pressure between the high density polyethylene sheets and carbon nano papers Pressure, hold for 20 seconds, natural cooling, carbon nano-reinforced high-density polyethylene composite.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com