Preparation method of metallization layer on surface of AIN film

A metallized layer and film surface technology, applied in metal material coating process, coating, ion implantation plating, etc., can solve the problems of weak bonding between the substrate and the metal film, poor structural stability, and difficult sintering of AlN substrates. Achieve the effects of low price, stable structure and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0036] The specific preparation process and steps in this embodiment are as follows:

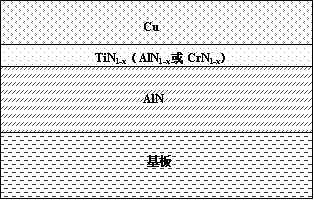

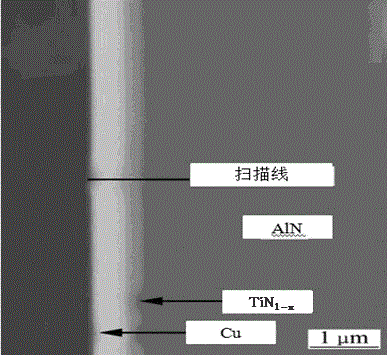

[0037] (1) AlN film is grown on Si substrate by magnetron sputtering method. Process parameters: the target material is Al target, the power is 280W, the gas flow rate of argon and nitrogen is 9sccm, and the sputtering time is 120min. The thickness of the grown AlN film is about 2 μm, and it grows preferentially along the c-axis (0001) direction.

[0038] (2) Growth of TiN on AlN film by magnetron sputtering 1-x (x=0-1) film. Process parameters: The target material is Ti target, the power is 100W, the flow rate of argon gas is 15 sccm, the flow rate of nitrogen gas is gradually reduced from 9 sccm to 0, and the sputtering time is 30 min. Growth of TiN with good orientation 1-x film, the thickness of the film is about 300nm.

[0039] (3) In Si / AlN / TiN 1-x Continue to grow Cu film on the composite film by magnetron sputtering. Process parameters: The target material is pure Cu target, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com