Preparation method of InN (indium nitride) thin film through low-temperature deposition on self-supporting diamond thick film by ECR-PEMOCVD (electron cyclotron resonance-plasma enhanced metal organic chemical vapor deposition)

A diamond thick film, self-supporting technology, applied in metal material coating process, gaseous chemical plating, coating, etc., can solve the problems of high decomposition temperature of nitrogen source, lack of substrate material, low growth temperature, etc., and achieve cost Low, excellent heat resistance, high thermal conductivity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

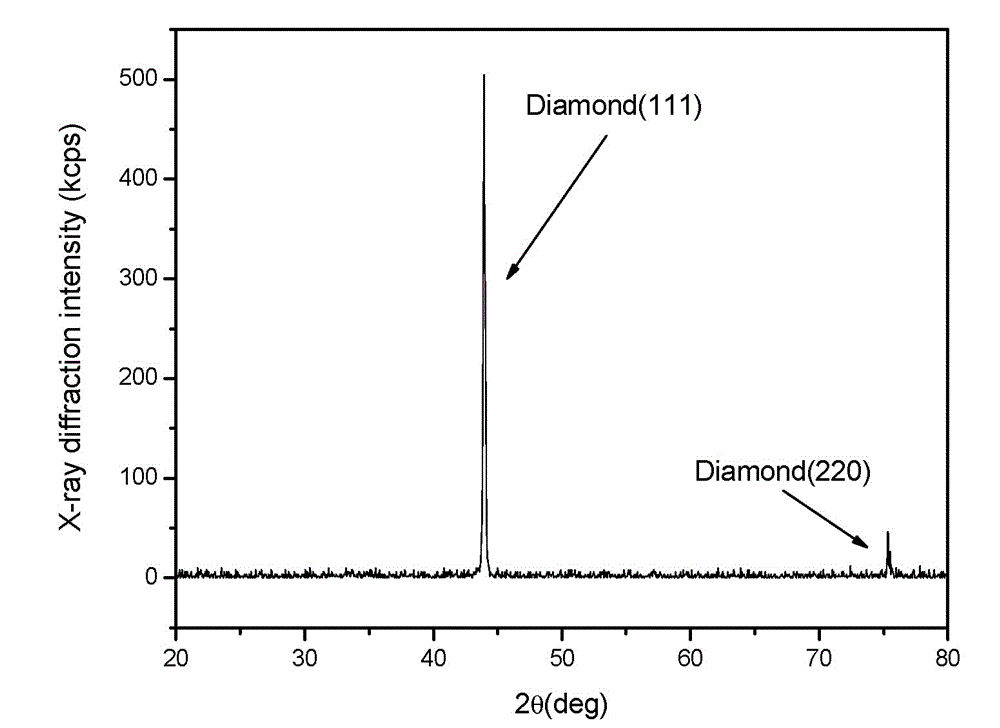

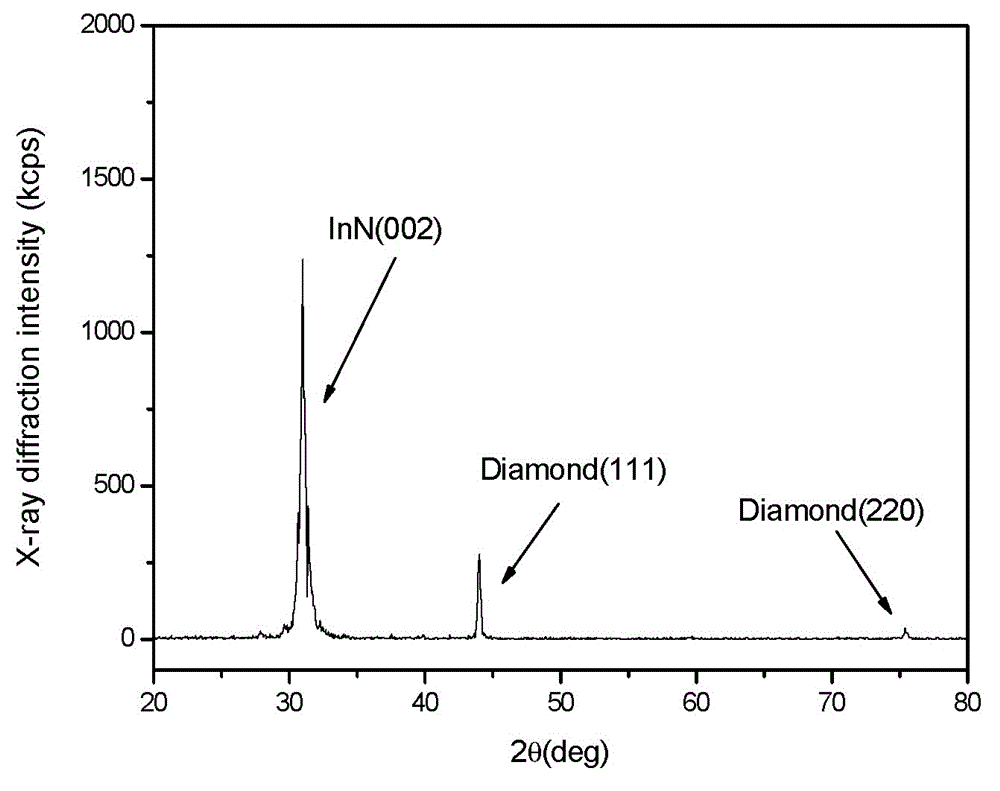

[0036] The free-standing diamond substrate was cleaned with acetone, ethanol and deionized water with ultrasonic in turn, dried with nitrogen and sent to the reaction chamber; the reaction chamber was evacuated to 9.0×10 -4 Pa, heat the substrate to 200℃, and pass trimethyl indium (TMIn) and nitrogen (N 2 ), where TMIn and N 2 The reaction source flow ratio is controlled at 1:100, controlled by the mass flowmeter, the flow parameters are 1 sccm and 100 sccm respectively; the total pressure of the control gas is 1.0Pa; the electron cyclotron resonance frequency is 650W, the reaction is 30min, and the self-supporting diamond thickness is obtained InN photoelectric film on the film substrate.

[0037] After the experiment, Hall test equipment was used to test and analyze the mobility and carrier concentration of the film. The results are shown in Table 1. It can be seen from Table 1 that the InN film on the free standing diamond substrate has good electrical properties, good mobilit...

Embodiment 2

[0041] The free-standing diamond substrate was cleaned with acetone, ethanol and deionized water with ultrasonic in turn, dried with nitrogen and sent to the reaction chamber; the reaction chamber was evacuated to 9.0×10 -4 Pa, heat the substrate to 500℃, and pass trimethyl indium (TMIn) and nitrogen (N 2 ), where TMIn and N 2 The reaction source flow ratio is controlled at 1:150, controlled by the mass flowmeter, the flow parameters are 1 sccm and 150 sccm respectively; the total pressure of the control gas is 2.0Pa; the electron cyclotron resonance frequency is 650W, the reaction is 50min, and the self-supporting diamond thickness is obtained InN photoelectric film on the film substrate.

[0042] After the experiment, Hall test equipment was used to test and analyze the mobility and carrier concentration of the film. The results are shown in Table 2. It can be seen from Table 2 that the InN film on the free standing diamond substrate has good electrical properties, good mobilit...

Embodiment 3

[0046] The free-standing diamond substrate was cleaned with acetone, ethanol and deionized water with ultrasonic in turn, dried with nitrogen and sent to the reaction chamber; the reaction chamber was evacuated to 9.0×10 -4 Pa, heat the substrate to 600℃, and pass trimethyl indium (TMIn) and nitrogen (N 2 ), where TMIn and N 2 The reaction source flow ratio is controlled at 2:200, controlled by the mass flowmeter, the flow parameters are 2 sccm and 200 sccm respectively; the total pressure of the control gas is 1.5Pa; the electron cyclotron resonance frequency is 650W, the reaction is 120min, and the self-supporting diamond thickness is obtained InN photoelectric film on the film substrate.

[0047] After the experiment, Hall test equipment was used to test and analyze the mobility and carrier concentration of the film. The results are shown in Table 3. From Table 3, it can be seen that the InN film on the free standing diamond substrate has good electrical properties, good mobil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com