Nitrile rubber composition, crosslinking nitrile rubber composition, and crosslinked rubber product

A technology of nitrile rubber and composition, which is applied in the field of nitrile rubber composition, cross-linkable nitrile rubber composition and rubber cross-linked products, can solve the problems of deterioration of cold resistance, achieve gasoline permeability resistance and cold resistance excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

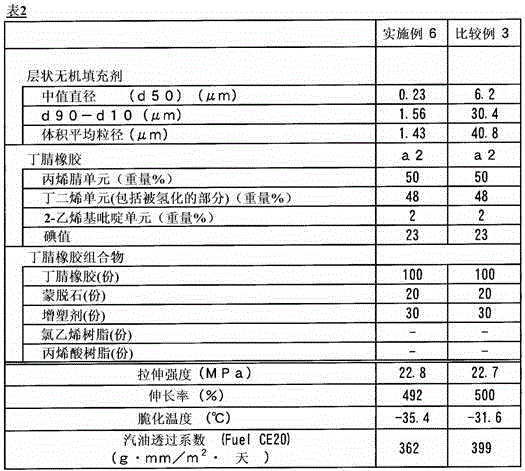

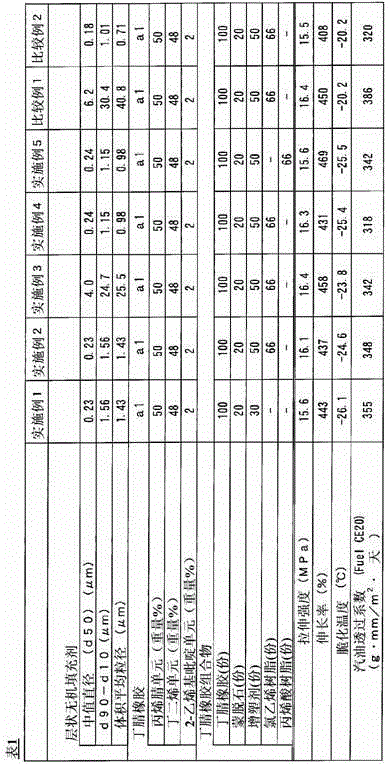

[0142] Hereinafter, although an Example and a comparative example are given and this invention is demonstrated more concretely, this invention is not limited to this Example. Hereinafter, unless otherwise specified, "parts" are based on weight. The test or evaluation methods of physical properties and characteristics are as follows.

[0143] (1) Mooney viscosity

[0144] Mooney viscosity of nitrile rubber (A) (polymer Mooney viscosity) (ML 1+4 , 100°C) was measured in accordance with JIS K6300.

[0145] (2) Normal physical properties (tensile strength and elongation)

[0146] The cross-linkable nitrile rubber composition was put into a mold having a length of 15 cm, a width of 15 cm, and a depth of 0.2 cm, and was press-molded at 160° C. for 20 minutes while pressurizing at 10 MPa to obtain a sheet-like rubber cross-linked product. The obtained sheet-like cross-linked rubber was punched out with a JIS No. 3 dumbbell to prepare a test piece. The tensile strength and elonga...

manufacture example 1

[0154] (production of latex of nitrile rubber (a1))

[0155] 240 parts of water, 75.7 parts of acrylonitrile, 2.2 parts of 2-vinylpyridine, and 2.5 parts of sodium dodecylbenzenesulfonate (emulsifier) were put into the reaction container, and the temperature was adjusted to 5°C. Next, the gas phase was decompressed and degassed sufficiently, and then 22 parts of 1,3-butadiene, 0.06 parts of terpane hydroperoxide as a polymerization initiator, 0.02 parts of sodium ethylenediaminetetraacetate, ferrous sulfate (Heptahydrate salt) 0.006 part and 0.06 part of sodium formaldehyde sulfoxylate and 1 part of tertiary dodecyl mercaptan as a chain transfer agent start the reaction of the first stage of emulsion polymerization. After the reaction started, when the polymerization conversion rate relative to the input monomer reached 40% by weight and 60% by weight, 12 parts and 12 parts of 1,3-butadiene were supplemented in the reaction vessel respectively, and the second stage and The ...

manufacture example 2

[0158] (production of latex of hydrogenated nitrile rubber (a2))

[0159] Use the latex of the nitrile-butadiene copolymer rubber (a1) that obtains in the same manner as Production Example 1, add palladium catalyst (the solution that 1% by weight palladium acetate acetone solution and equal weight ion-exchanged water are mixed) in reactor, A hydrogenation reaction was performed at a hydrogen partial pressure of 3 MPa and a temperature of 50° C. for 6 hours so that the palladium content was 1000 ppm based on the dry rubber weight contained in the latex to obtain a latex of hydrogenated nitrile rubber (a2).

[0160] The content ratio of each monomer unit constituting the obtained hydrogenated nitrile rubber (a2) was measured in the same manner as in Production Example 1. As a result, 50% by weight of an acrylonitrile monomer unit, 1,3-butadiene unit, and saturated butadiene The sum of the units is 48% by weight, and the 2-vinylpyridine monomer unit is 2% by weight. In addition,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap