Preparation method of polyethylene glycol microcapsule used as composite phase change and energy storage material

A polyethylene glycol, phase change energy storage technology, applied in microcapsule preparations, microsphere preparation, heat exchange materials, etc. The effect of low requirements and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

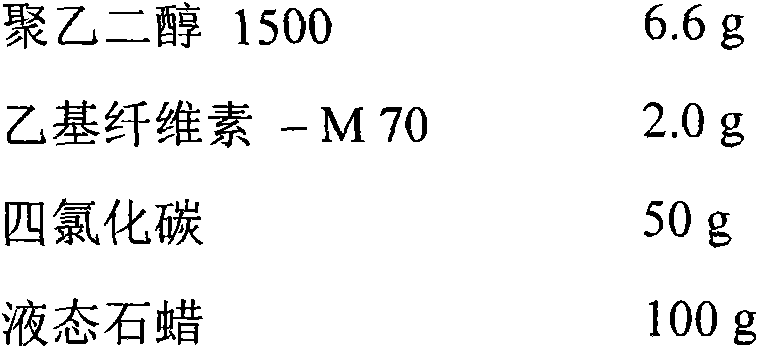

[0020] Prepare the quality of each component of polyethylene glycol / ethyl cellulose microcapsule as follows:

[0021]

[0022] The preparation method of polyethylene glycol / ethyl cellulose microcapsules is as follows:

[0023] (1) Heat 6.6g of polyethylene glycol 1500 into a liquid state and add it into 50g of carbon tetrachloride dissolved in 2g of ethyl cellulose, and ultrasonically vibrate for 60min to form a mixed solution;

[0024] (2) Take 100g of liquid paraffin with a melting point of 17°C in a three-necked flask, stir at a speed of 100rpm, and control the temperature at 30°C;

[0025] (3) The mixed solution obtained in (1) is dripped into the liquid paraffin in (2) at a speed of 1.5mL / min, after dripping, continue to stir for 120min, and keep the temperature and stand for 120min;

[0026] (4) down to room temperature, suction filtration, washing with normal hexane, drying, removing liquid paraffin and normal hexane on the surface of microcapsules, washing with wat...

Embodiment 2

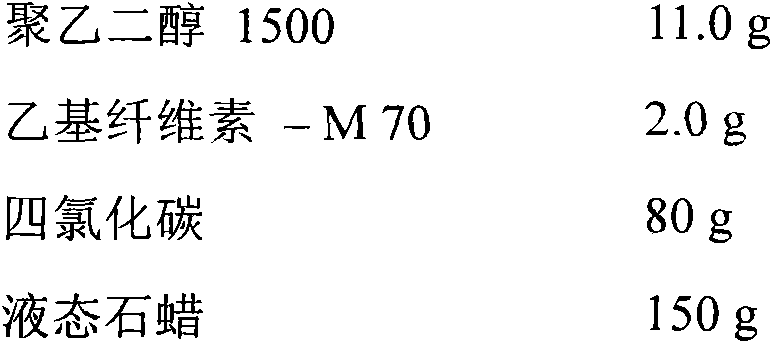

[0029] Prepare the quality of each component of polyethylene glycol / ethyl cellulose microcapsule as follows:

[0030]

[0031] The preparation method of polyethylene glycol / ethyl cellulose microcapsules is as follows:

[0032] (1) Heat 11.0 g of polyethylene glycol 1500 into a liquid state, add 2.0 g of ethyl cellulose to 80 g of carbon tetrachloride, and ultrasonically vibrate for 60 minutes to form a mixed solution;

[0033] (2) Take 150 g of liquid paraffin with a melting point of 17° C. in a three-necked flask, stir at a speed of 1500 rpm, and control the temperature at 30° C.;

[0034] (3) Drop the mixed solution obtained in (1) into the liquid paraffin in (2) at a rate of 1.0 mL / min, continue to stir for 120 min after dripping, and keep the temperature for 120 min;

[0035] (4) down to room temperature, suction filtration, washing with n-hexane, drying, removing liquid paraffin and n-hexane on the surface of microcapsules, washing with water, removing polyethylene gl...

Embodiment 3

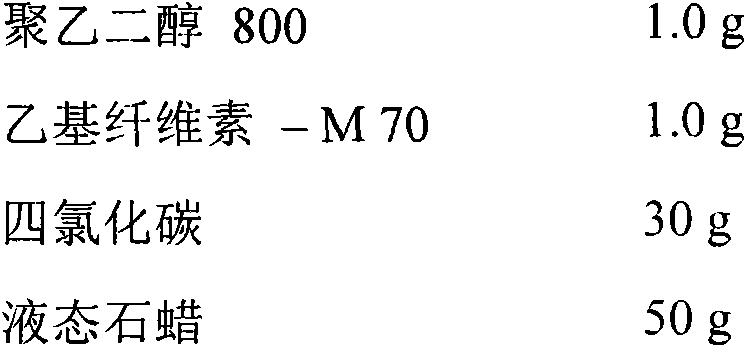

[0038] Prepare the quality of each component of polyethylene glycol / ethyl cellulose microcapsule as follows:

[0039]

[0040] The preparation method of polyethylene glycol / ethyl cellulose microcapsules is as follows:

[0041] (1) Heat 1.0 g of polyethylene glycol 800 into a liquid state, add it into 30 g of carbon tetrachloride dissolved in 1.0 g of ethyl cellulose, and ultrasonically vibrate for 60 minutes to form a mixed solution;

[0042] (2) Take 50 g of liquid paraffin with a melting point of 14°C in a three-necked flask, stir at a speed of 500 rpm, and control the temperature at 25°C;

[0043] (3) Drop the mixed solution obtained in (1) into the liquid paraffin in (2) at a rate of 1.0 mL / min, continue to stir for 120 min after dripping, and keep the temperature for 120 min;

[0044] (4) down to room temperature, suction filtration, washing with n-hexane, drying, removing liquid paraffin and n-hexane on the surface of microcapsules, washing with water, removing polye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com