Physical preparation method of nano-lead and cadmium sulfide material

A lead cadmium sulfide and nanotechnology, applied in the direction of lead sulfide, cadmium sulfide, nanotechnology, etc., can solve the problem of uneven composition of nanocrystals, and achieve the effect of easy-to-obtain raw materials, uniform chemical composition, and single structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] In the following, the present invention will be further described in conjunction with the preparation examples and spectra of the samples.

[0025] The preparation method of nano lead cadmium sulfide material comprises the following steps:

[0026] 1) The mixture of high-purity cadmium, lead and sulfur powder is sealed in a ball mill jar as a raw material, and the molar ratio of the sum of cadmium and lead to sulfur is (1±0.1):(1±0.1), while cadmium and lead The molar ratio is any value from 0 to 1, and ball mills of different diameters are loaded into the ball mill tank at the same time;

[0027] 2) Put the sealed ball milling tank in the glove box, then open the ball milling tank cover, and fill the ball milling tank with inert gas to remove the oxygen in the raw materials;

[0028] 3) Install the sealed ball mill tank on the ball mill to start ball milling, so that the element powder is mechanically alloyed into the desired semiconductor compound or nanocrystal;

...

Embodiment 1

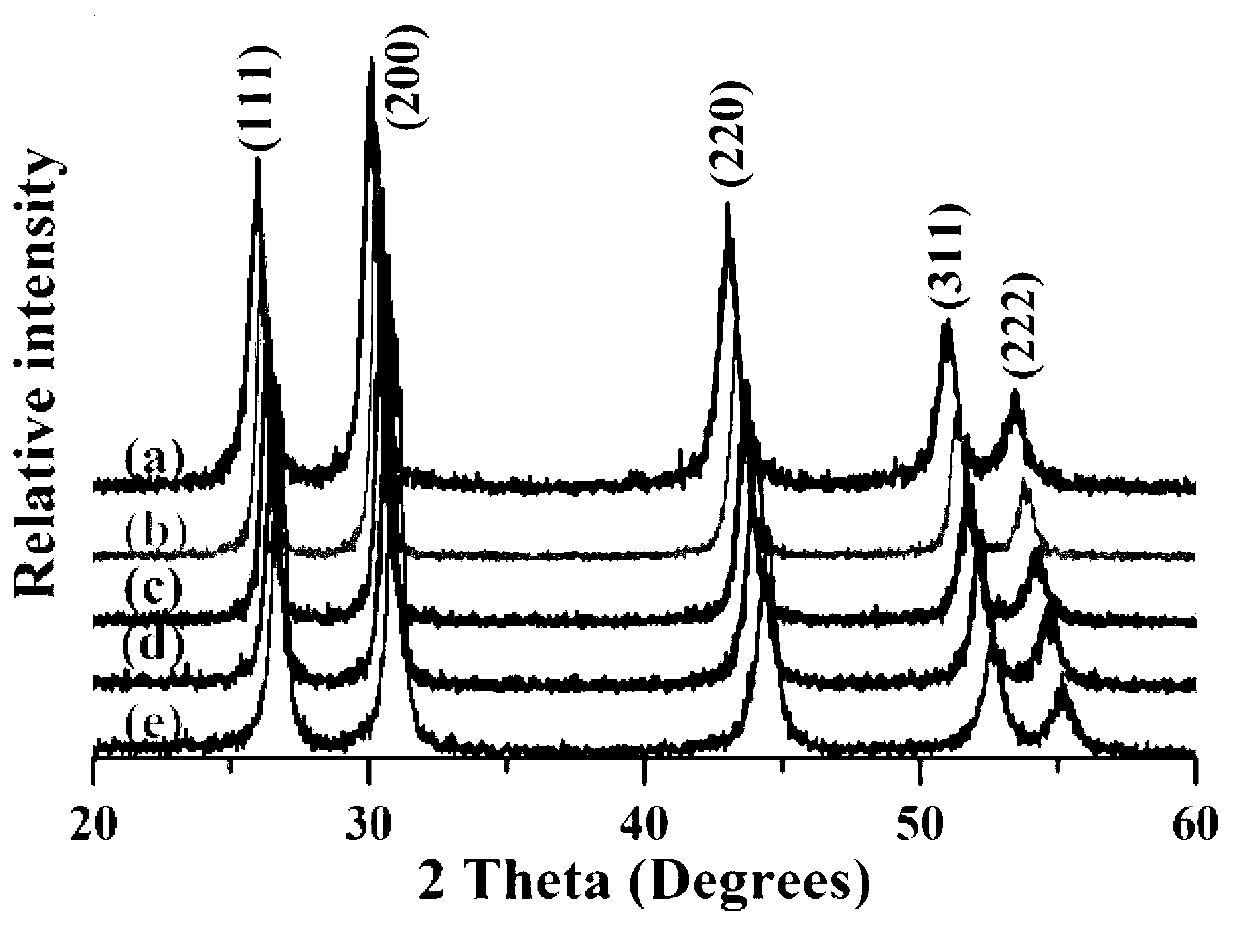

[0038]CdS nanocrystals were prepared by mechanical alloying, that is, x=0, and the samples were weighed according to the stoichiometric ratio of CdS. In order to avoid excessive Cd, the atomic ratio of Cd to S was set to 0.46:0.54, and then the elements Cd and S powder were weighed 11.2371g and 3.7628g each, the weighing error is ±0.0002g, the purity of high-purity cadmium and sulfur is 99.9% (the same below), put the weighed samples into ball mill jars with ball mills of different diameters And sealed, the diameter of the ball mill is 2-12 mm, the mass ratio of the ball mill to the raw material is set to 1:1~10:1, put it in the glove box, open the ball mill tank cover, and fill the ball mill tank with inert gas for 30 minutes , to remove the oxygen in the raw material, take it out after sealing, load it on the ball mill (SPEX8000) of SPEX SpamplePrep Company in the United States for ball milling, and ball mill for 1 to 40 hours, so that the element powder can completely react ...

Embodiment 2

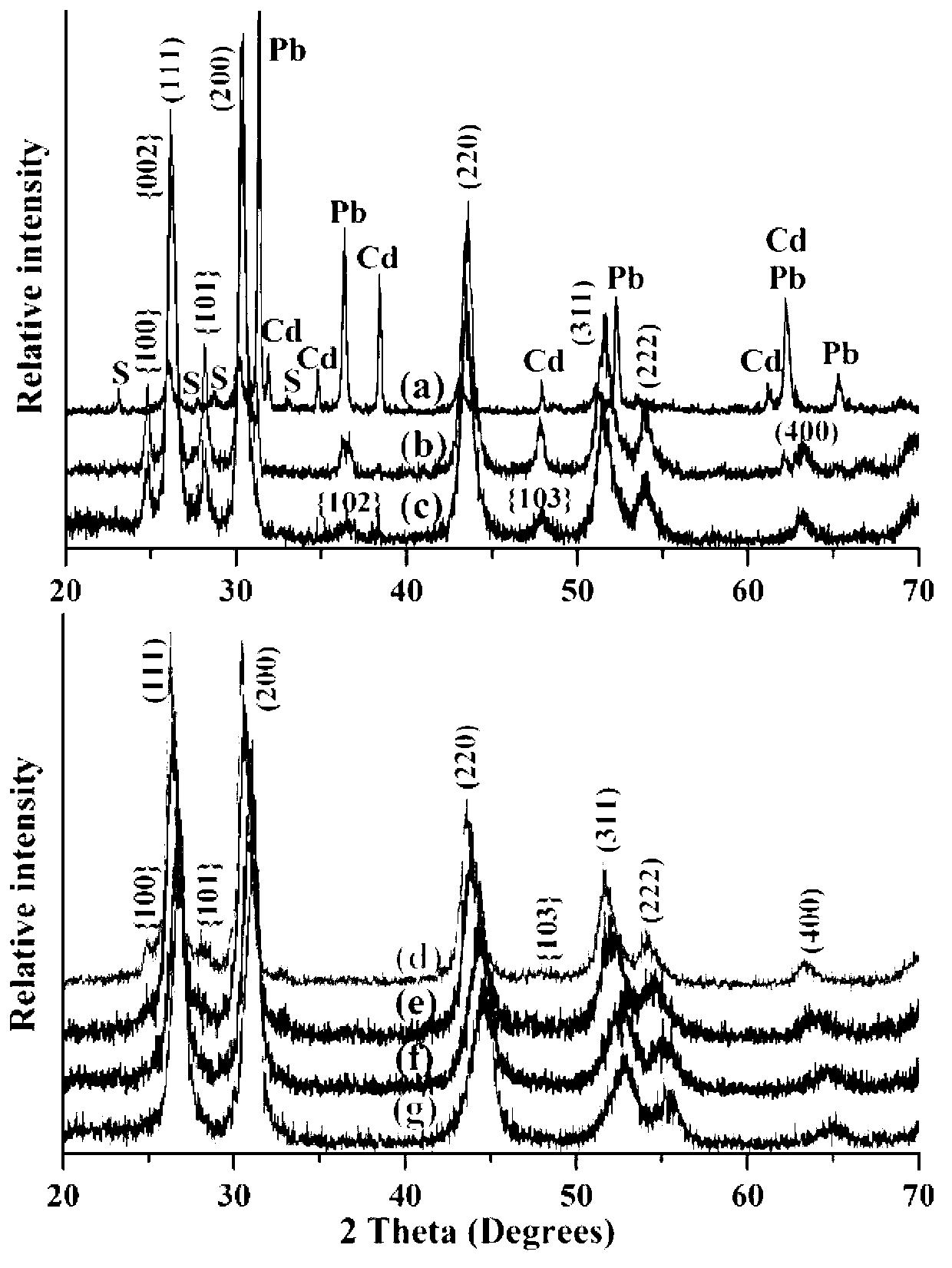

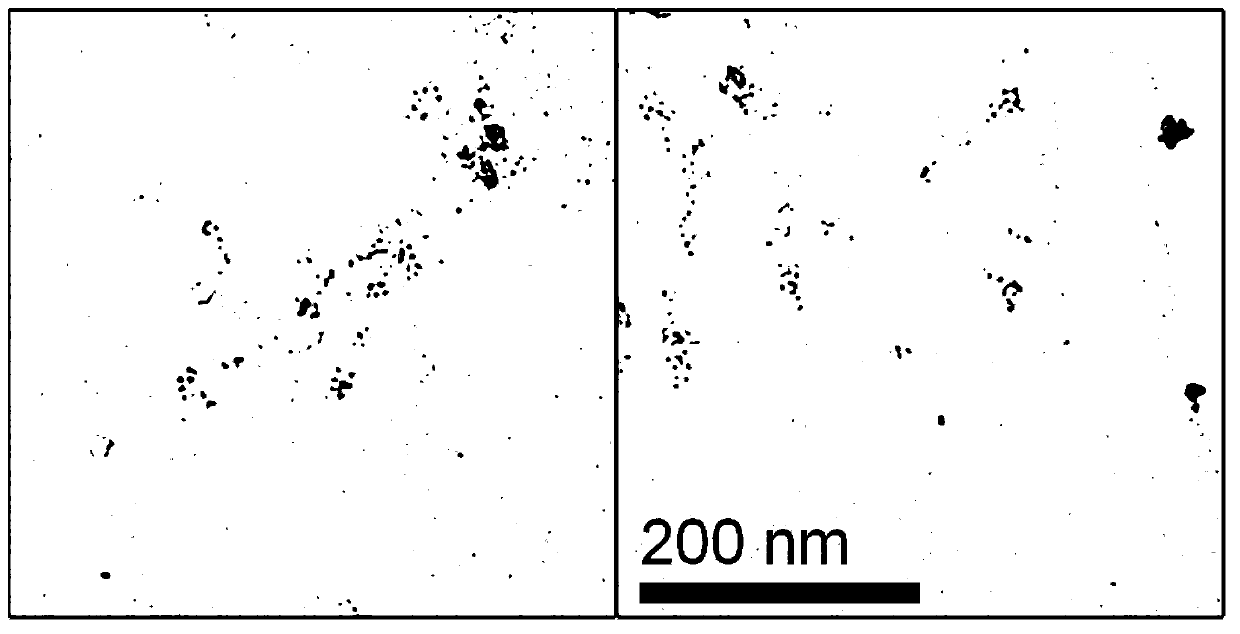

[0040] Preparation of Cd by Mechanical Alloying 0.5 Pb 0.5 S nanocrystals, that is, x=0.5; Weigh 4.3939g, 8.0992g and 2.5067g of elemental Cd, Pb and S powder respectively, keep the weighing error within the range of ±0.0002g, place the weighed sample in the There are ball mill jars with different diameters and sealed. The diameter of the ball mill is 2-12 mm. The mass ratio of the ball mill to the raw material is set at 1:1 to 10:1. Put it in the glove box and open the lid of the ball mill jar. Fill the ball mill tank with inert gas for 30 minutes to remove the oxygen in the raw materials, seal it and take it out, load it on the ball mill (SPEX8000) of SPEX SpamplePrep Company in the United States for ball milling, and ball mill for 15 minutes, 30 minutes, 60 minutes, 2 hours, 5 hours, 10 hours, 20 hours, 40 hours, the samples of different ball milling times should be sampled in the glove box for structural and optical performance tests to avoid oxidation. XRD tests were ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Energy gap | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com