Method for preparing stable insulin aspart crystal

A technology for the crystallization of insulin aspart, which is applied in the field of purification and preparation of artificial insulin, can solve problems such as inability to form crystals, and achieve the effects of high production efficiency, small sedimentation volume, and shortened freeze-drying time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Prepare recombinant insulin aspart crystallization liquid, each component and concentration are: experiment A is 1.2M glycine system, experiment B is 1.5M glycine system, other components are the same: recombinant insulin aspart: 3.0g / L, acetonitrile: volume fraction content 12%, phenol: volume fraction content is 0.2%, zinc acetate: the molar ratio of zinc ion to insulin aspart is 7.35:1, sodium chloride: 0.34M (20g / L).

[0038] Prepare a recombinant insulin aspart solution with a concentration of 6.0 g / L, in which the volume fraction of acetonitrile is 24%, and adjust the pH value to 6.0 for use. Weigh 1.36g and 1.69g of glycine and put them in 50ml Erlenmeyer flasks, respectively add 0.3g of sodium chloride, add 7.3ml of purified water to dissolve it, then add 7.5ml of 6.0g insulin aspart samples, and then add 30ul of water-saturated phenol, adjust the pH value to 6.0, and finally add 160ul of zinc acetate solution with a concentration of 0.355M to start the crystall...

Embodiment 2

[0040] Prepare recombinant insulin aspart crystallization liquid, each component and concentration are: experiment A contains 0.5M sodium chloride, experiment B contains 0.2M sodium chloride, other ingredients are the same: glycine: 1.2M, recombinant insulin aspart: 6.0g / L, acetonitrile: volume fraction content is 12%, phenol: volume fraction content is 0.4%, zinc acetate: insulin aspart content molar ratio is 3:1.

[0041] Prepare a recombinant insulin aspart solution with a concentration of 12.0 g / L, in which the volume fraction of acetonitrile is 24%, and adjust the pH value to 6.0 for use. Weigh 0.45g and 0.18g of sodium chloride and put them in 50ml Erlenmeyer flasks, respectively add 1.36g of glycine, add 7.3ml of purified water to dissolve it, then add 7.5ml of 12.0g of insulin aspart samples, and then add 60ul of water-saturated phenol, adjust the pH value to 6.2, and finally add 130ul of zinc acetate solution with a concentration of 0.355M to start the crystallizatio...

Embodiment 3

[0042] Embodiment 3 (comparative embodiment)

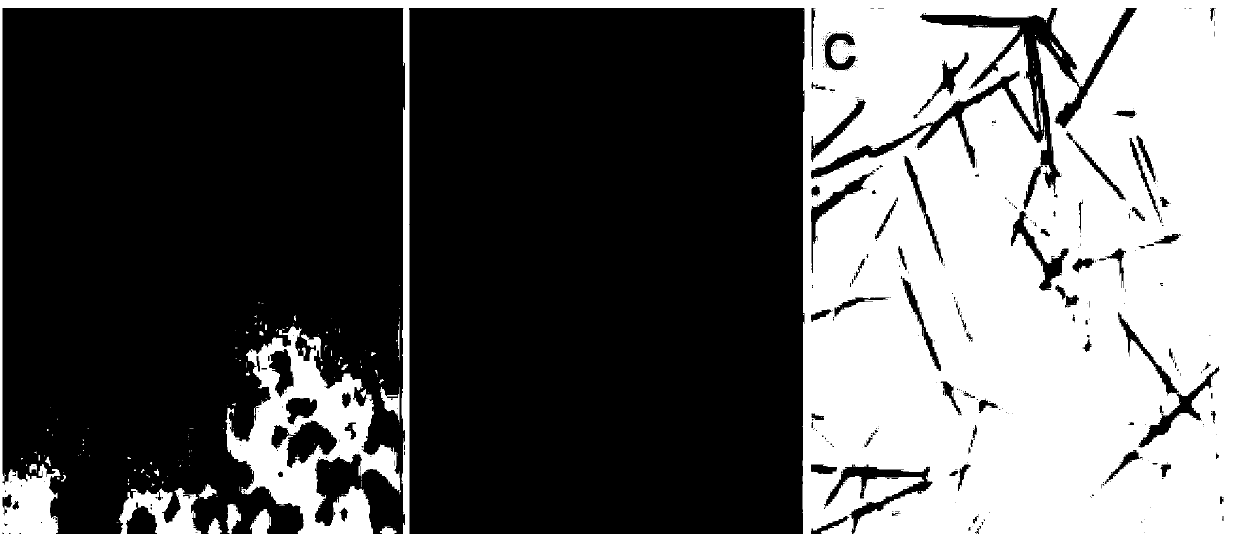

[0043] Preparation of recombinant insulin aspart crystallization solution, the components and concentrations are: Experiment A According to the Chinese patent CN95106555.6 insulin lispro crystallization process, a 15ml crystallization system was prepared, containing acetic acid: 1M, recombinant insulin aspart: 2.5g / L, acetic acid Zinc: 200mg / L, phenol: 0.2% volume fraction, pH6.0; Experiment B added acetonitrile on the basis of Experiment A, and the volume fraction content was 12%; Experiment C added sodium chloride on the basis of Experiment B, The concentration is 0.34M (20g / L). The result is as image 3 Shown: 40X magnification, Experiments A and B are amorphous precipitates (see image 3 a and image 3 b), Insulin aspart monoclinic needle-like crystals formed in experiment C have relatively poor uniformity, and the needle-like crystals are fragile and difficult to follow up (see image 3 c).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com